Fragile armor-piercing shell W alloy and preparation method thereof

A technology of armor-piercing projectiles and tungsten alloys, which is applied in the field of alloys, can solve the problems of difficult secondary blasting, low compressive strength, and insufficient effects, and achieve good plasticity, reduce tensile strength, and improve fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

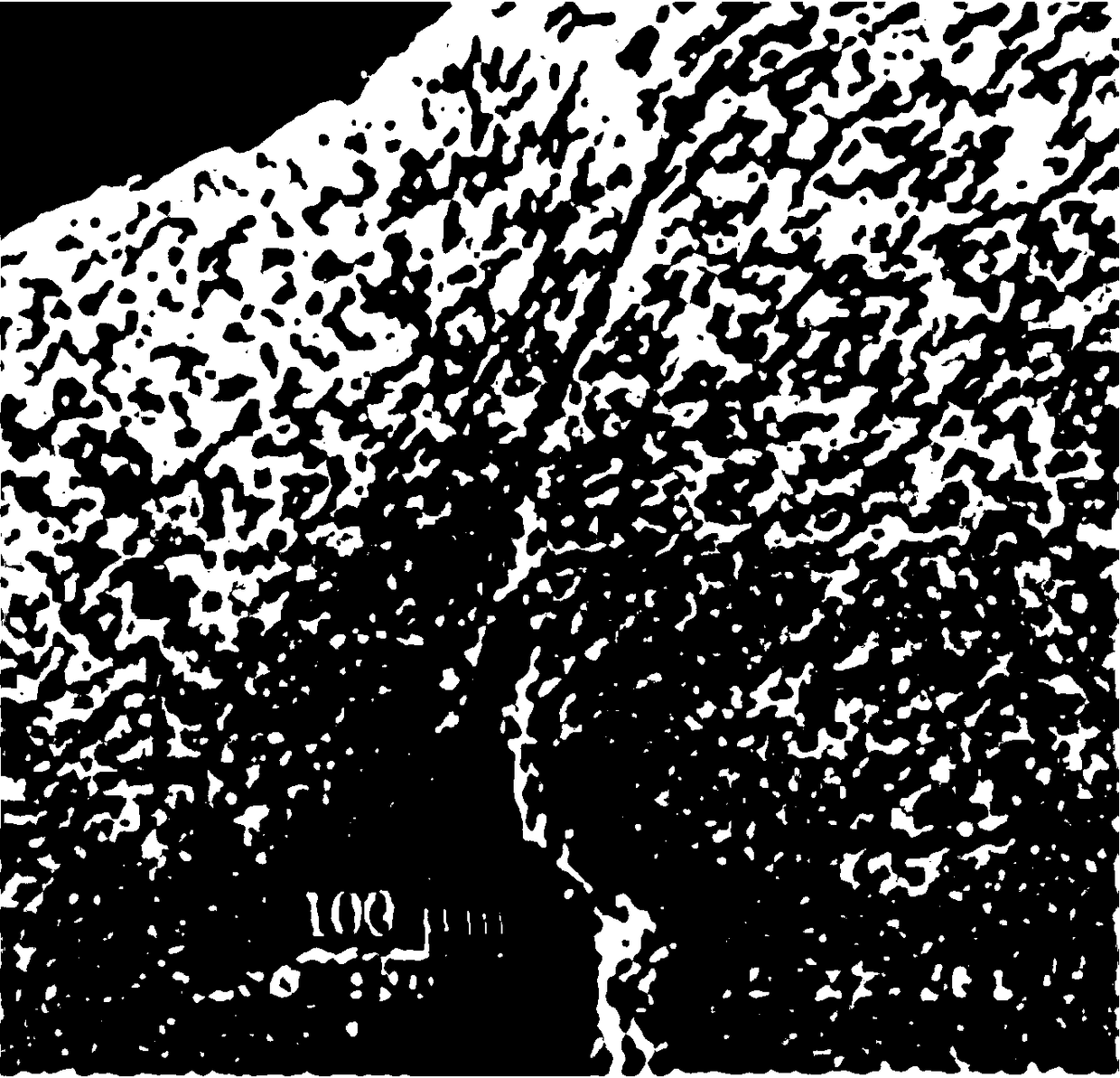

Image

Examples

Embodiment 1

[0038] By weight percentage:

[0039] W powder 97.8%, Fibonacci particle size 3.0μm, purity 99.9%;

[0040] Ni powder 1.1%, Fischer particle size 3.66μm, purity 99.5%;

[0041] The Fe powder is 1.1%, the Fibonacci particle size is 3.97μm, and the purity is 99.3%.

[0042] Mix the above powders into a three-dimensional mixer for mixing, and then ball mill in a steel ball mill cylinder. The ball milling medium is anhydrous alcohol, the balls for ball milling are hard alloy balls, the ball-to-material ratio is 2:1, and the ball milling time is 10 hours. , the speed is 300r / min.

[0043] Dry the wet-mixed slurry in a vacuum drying oven at a drying temperature of 100-120° C. for 2 hours, and pass through an 80-mesh sieve after drying.

[0044] Add additive, additive selects paraffin gasoline solution for use, dissolves 10g paraffin wax preparation solution with 50ml gasoline, during the addition amount, 100g raw material powder is mixed with paraffin wax 2g.

[0045] Dry and si...

Embodiment 2

[0052] By weight percentage:

[0053] W powder 97%, Fischer particle size 3.0μm, purity 99.9%;

[0054] Ni powder 1.1%, Fischer particle size 3.66μm, purity 99.5%;

[0055] Fe powder 1.1%, Fibonacci particle size 3.97μm, purity 99.3%;

[0056] Re powder 0.8%, Fibonacci particle size 3.54μm, purity 99.99%.

[0057] Mix the above powders into a three-dimensional mixer for mixing, and then ball mill in a steel ball mill cylinder. The ball milling medium is anhydrous alcohol, the balls for ball milling are hard alloy balls, the ball-to-material ratio is 2:1, and the ball milling time is 10 hours. , the speed is 300r / min.

[0058] Dry the wet-mixed slurry in a vacuum drying oven at a drying temperature of 100-120° C. for 2 hours, and pass through an 80-mesh sieve after drying.

[0059] Add additive, additive selects paraffin gasoline solution for use, dissolves 10g paraffin wax preparation solution with 50ml gasoline, during the addition amount, 100g raw material powder is mixe...

Embodiment 3

[0064] By weight percentage:

[0065] W powder 97%, Fischer particle size 3.0μm, purity 99.9%;

[0066] Ni powder 1.1%, Fischer particle size 3.66μm, purity 99.5%;

[0067] Fe powder 1.1%, Fibonacci particle size 3.97μm, purity 99.3%;

[0068] Re powder 0.8%, Fibonacci particle size 3.54μm, purity 99.99%.

[0069] Add the mixed powder into Al according to the weight ratio of 3% 2 o 3 , Al 2 o 3 The diameter of the powder is 0.67μm, and the above powder is mixed into a three-dimensional mixer for mixing, and then ball milled in a steel ball mill cylinder. The ball milling medium is anhydrous alcohol, and the balls for ball milling are cemented carbide balls. : 1, the ball milling time is 10h, and the rotating speed is 300r / min.

[0070] Dry the wet-mixed slurry in a vacuum drying oven at a drying temperature of 100-120° C. for 2 hours, and pass through an 80-mesh sieve after drying.

[0071] Add additive, additive selects paraffin gasoline solution for use, dissolves 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com