Steel for machine structural use excellent in friability of chips

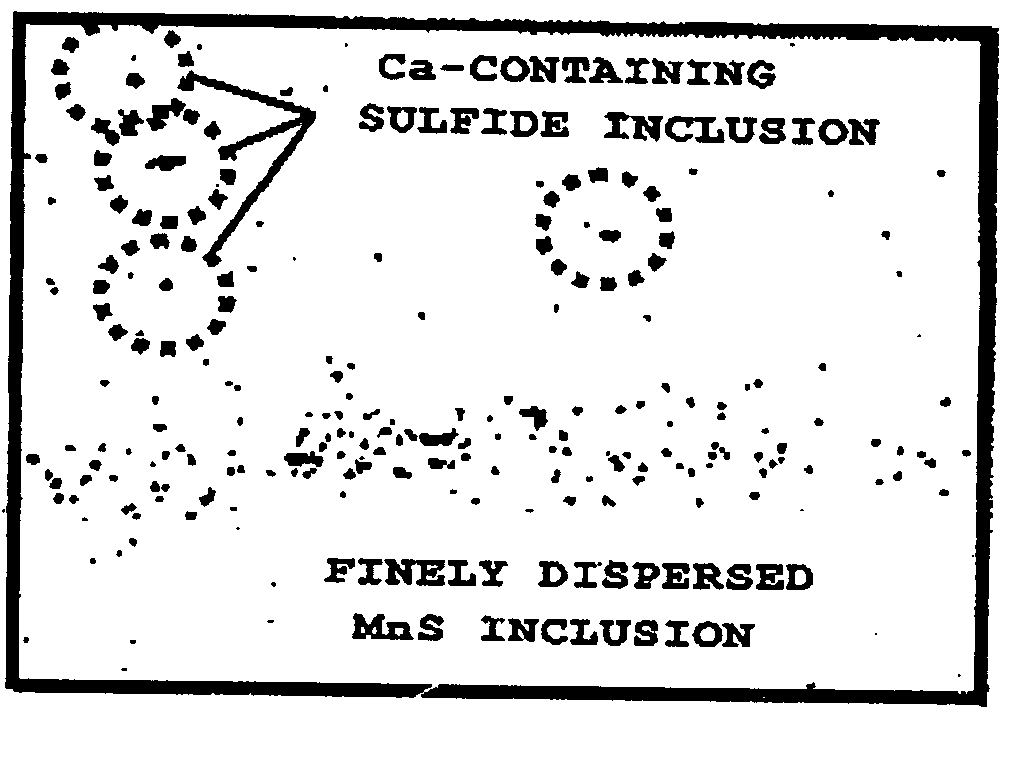

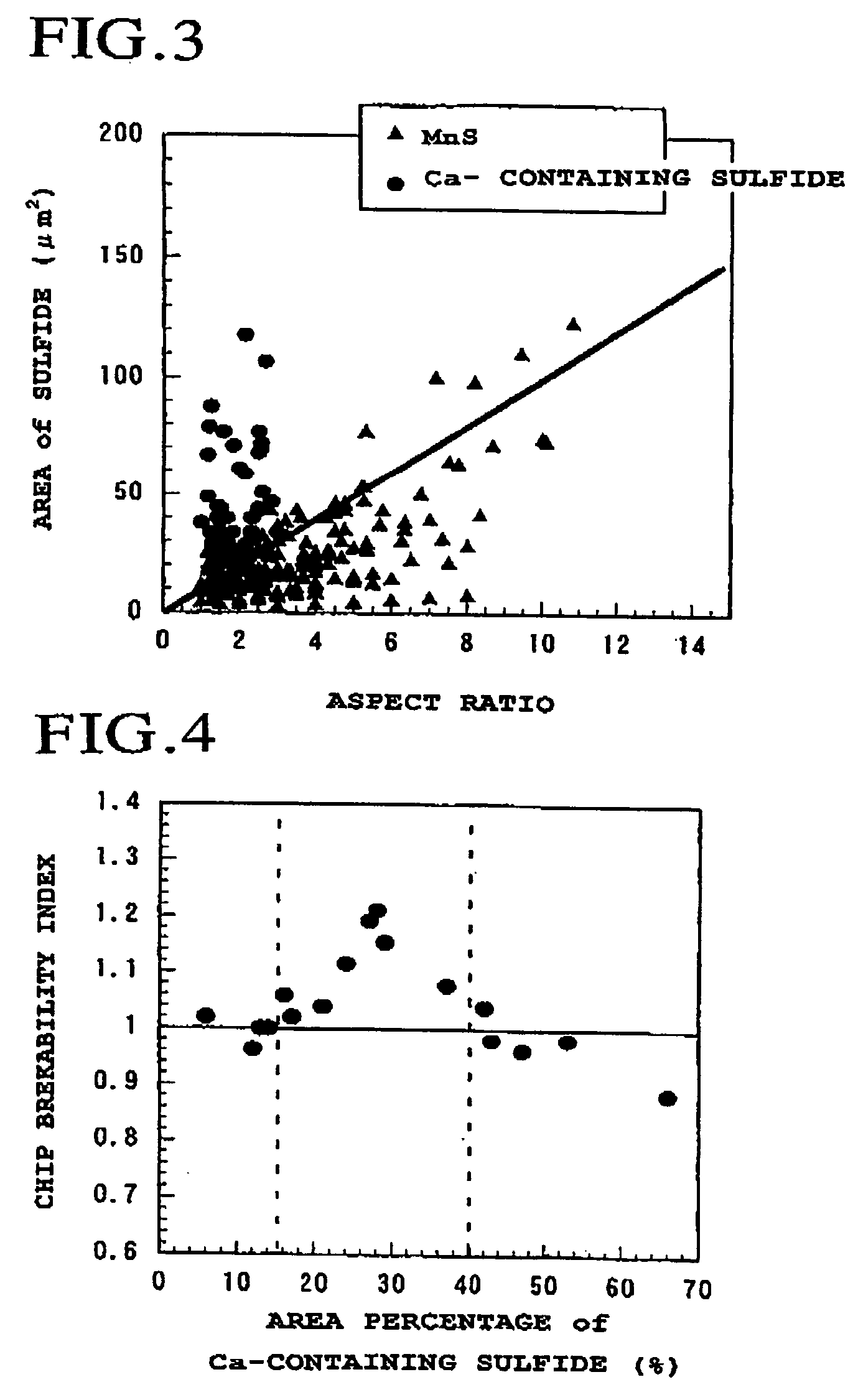

a technology of steel and structural use, applied in the field of steel for machine structural use, can solve the problems of unsatisfactory chip breakability, obstructing automation, and machining chip breakability, and achieve the effect of improving chip breakability, good tool life, and facilitating automation of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043] The present invention was applied to S45C steels. The prepared steels were cast into ingots, and from the ingots test pieces in the form of round rods of diameter 72 mm were taken, and subjected to the tests. The alloy compositions and the test results are shown in TABLE 2 (working examples) and TABLE 3 (control examples).

example 2

[0044] In regard to S15C free cutting steel preparation of the steels and the cutting tests were carried out as done in Example 1. The alloy compositions and the test results are shown in TABLE 4 (working examples) and TABLE 5 (control examples).

example 3

[0045] In regard to S55C free cutting steel preparation of the steels and the cutting tests were carried out as done in Example 1. The alloy compositions and the test results are shown in TABLE 6 (working examples) and TABLE 7 (control examples).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com