Hordeum Vulgare L. var. nudum Hook. F nutritive coarse cereal instant noodles and processing method thereof

A processing method and technology of instant noodles, which are applied in the direction of food ingredients as taste improvers, food ingredients as odor improvers, food ingredients as taste improvers, etc., can solve the problem of no obvious nutritional advantages of ordinary instant noodles, discount of nutritional value of highland barley instant noodles, and influence The safety of highland barley instant noodles can avoid the generation of toxic substance acrylamide, the taste is no longer rough, and the effect of improving friability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The highland barley nutritious miscellaneous grain instant noodles include the following raw materials in parts by weight: 60 parts of highland barley, 6 parts of millet, 8 parts of whole potato flour, 1 part of quinoa, 0.5 part of vegetable oil, 24 parts of purified water, 0.3 part of edible salt, and 1.5 parts of starch improver.

[0033] The starch improver is composed of the following components by weight: 3 parts of wheat protein, 0.2 part of artemisia gum, 0.02 part of sodium polyacrylate, 0.05 part of β-cyclodextrin, and 1 part of lotus root powder.

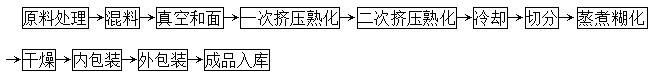

[0034] Highland barley nutritional miscellaneous grains instant noodles such as figure 1 The shown processing technology specifically includes the following steps:

[0035] (1) Raw material preparation. First, the highland barley was roasted at 85°C for 120 minutes at low temperature. After cooling, it was pulverized by a cup mill and passed through a 120-mesh sieve to obtain highland barley flour. Millet and quino...

Embodiment 2

[0044] The highland barley nutritious miscellaneous grain instant noodles include the following raw materials in parts by weight: 80 parts of highland barley, 15 parts of millet, 16 parts of whole potato powder, 4 parts of quinoa, 2.0 parts of vegetable oil, 44 parts of purified water, 0.6 part of edible salt, and 3.5 parts of starch modifier.

[0045] The starch improver is composed of the following components in weight ratio: 8 parts of wheat protein, 0.8 part of artemisia gum, 0.08 part of sodium polyacrylate, 0.12 part of β-cyclodextrin, and 4 parts of lotus root powder.

[0046] Highland barley nutritional miscellaneous grains instant noodles such as figure 1 The shown processing technology specifically includes the following steps:

[0047] (1) Raw material preparation. First, the highland barley was roasted at 85°C for 120 minutes at low temperature. After cooling, it was pulverized by a cup mill and passed through a 120-mesh sieve to obtain highland barley flour. Mill...

Embodiment 3

[0056] The highland barley nutritious miscellaneous grain instant noodles include the following raw materials in parts by weight: 70 parts of highland barley, 9 parts of millet, 12 parts of whole potato flour, 1 part of quinoa, 1.2 parts of vegetable oil, 32 parts of purified water, 0.5 part of edible salt, and 2.5 parts of starch improver.

[0057] The starch improver is composed of the following components by weight: 5 parts of wheat protein, 0.5 part of artemisia gum, 0.05 part of sodium polyacrylate, 0.08 part of β-cyclodextrin, and 2.5 parts of lotus root powder.

[0058] Highland barley nutritional miscellaneous grains instant noodles such as figure 1 The shown processing technology specifically includes the following steps:

[0059] (1) Raw material preparation. First, the highland barley was roasted at 85°C for 120 minutes at low temperature. After cooling, it was pulverized by a cup mill and passed through a 120-mesh sieve to obtain highland barley flour. Millet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com