Circulating Grinding Cement Vertical Mill with Preheating Grinding Function

A circulating grinding and cement technology, applied in the field of cement vertical mill, can solve the problems that local materials are difficult to grind and separate, and the uniformity of cement, mineral powder and other materials is difficult to be guaranteed, so as to achieve fine grinding fineness, improve grinding quality, and improve The effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

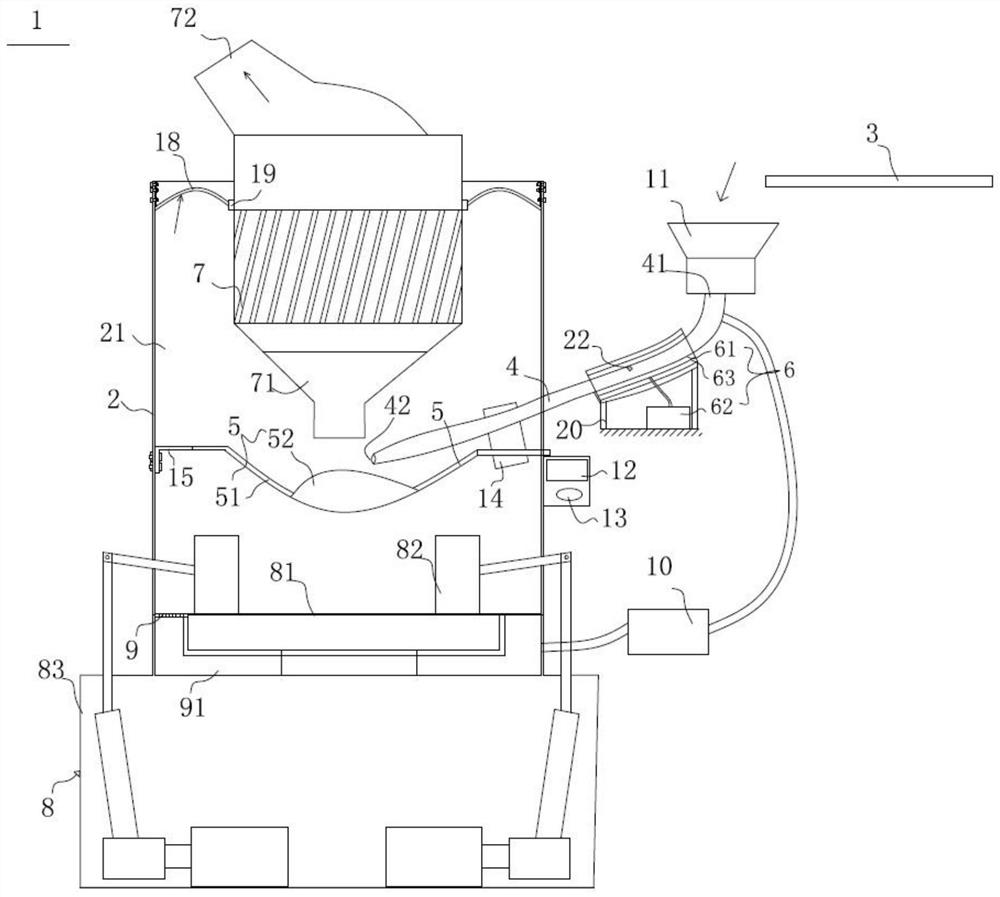

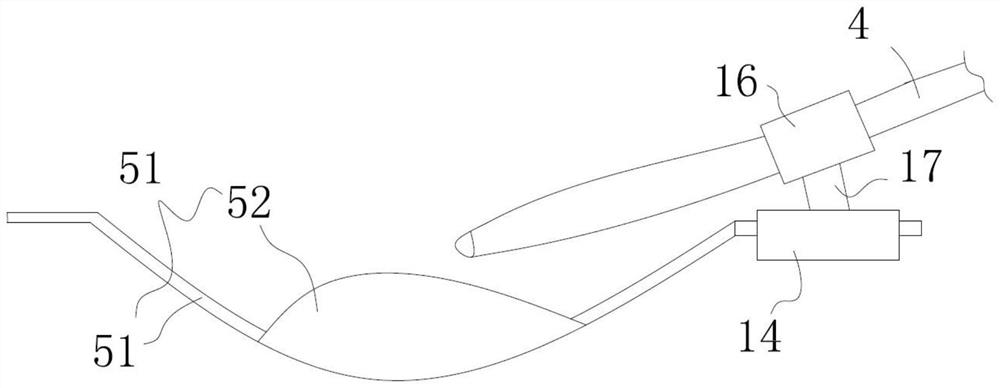

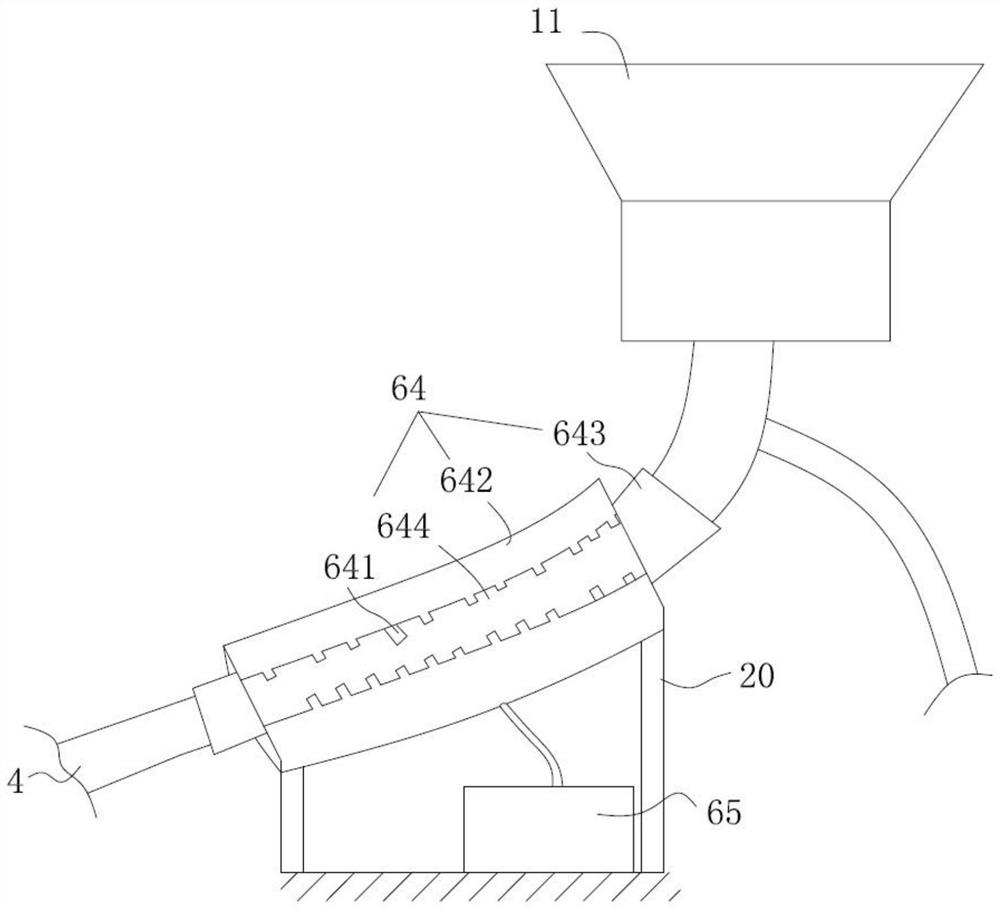

[0027] The present invention discloses an embodiment of a circulating grinding cement vertical mill 1 with preheating grinding function, please refer to Figure 1-4 As shown, for grinding cement materials, the circulating grinding cement vertical mill 1 with the function of preheating grinding includes a cylinder body 2, a conveying device 3, a crushing device 11, a feeding pipe 4, a material distributing device 5, a heating device 6, and a powder selecting device. Device 7, grinding device 8, sieve disc ring 9 and suction fan 10, wherein:

[0028] Please refer to figure 1 As shown, the cylinder body 2 has an accommodating space 21, and the cylinder body 2 mainly enables the circulating grinding cement vertical mill 1 with preheating grinding function of the present invention to grind and collect cement materials in the accommodating space 21. In the present invention There may be no special requirements for the selection of the structure of the cylinder body 2, just refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com