Carbon nanotube adsorption member, preparation method and application

A technology of carbon nanotubes and carbon nanotube arrays, which is applied in the field of carbon nanotube adsorption components and preparation, can solve the problems of reduced adsorption performance and loss of carbon nanotubes, and achieve equipment cost reduction, high space utilization, and large adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

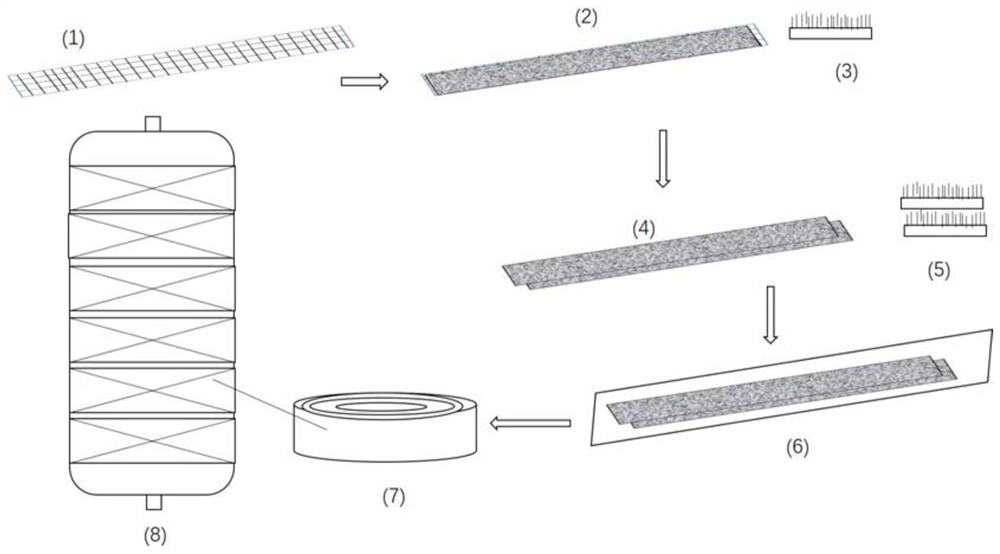

Embodiment 1

[0030] One side of the copper wire mesh belt was sprayed with a nickel-based catalyst capable of growing carbon nanotubes, and after heat treatment, it was placed in the reactor. At a temperature of 320° C. and a pressure of 0.1 MPa, a nitrogen gas of 160 ppm of xylene was introduced, and the reaction time was 60 minutes. After the carbon-containing process gas is cracked, a dense carbon nanotube array layer is formed on one side of the metal wire mesh; after the reaction is stopped, the copper wire mesh belt with the carbon nanotube array layer is taken out. The two layers of carbon nanotube array layers are inserted into each other to form a belt-like structure in which one side of the copper mesh belt where no carbon nanotubes are deposited is separated from the other side where the carbon nanotubes are deposited. After bundling and fixing the belt-like structure, it is packed with filter cloth on the outside for later use.

[0031] According to the inner diameter of the c...

Embodiment 2

[0034] One side of the copper wire mesh was sprayed with a nickel-based catalyst capable of growing carbon nanotubes, and after heat treatment, it was placed in the reactor. At a temperature of 500° C., a pressure of 1 MPa, and hydrogen containing 20% methane, the reaction time was 4 hours. After the carbon-containing process gas is cracked, a dense carbon nanotube array layer is formed on one side of the copper wire mesh belt; after the reaction is stopped, the copper wire mesh belt with the carbon nanotube array layer is taken out. Three copper wire mesh ribbons with carbon nanotube array layers are stacked to form a ribbon structure in which one side of the copper wire mesh ribbon is not deposited with carbon nanotubes and the other side where carbon nanotubes are deposited is spaced apart. After bundling and fixing the belt-like structure, it is packed with filter cloth on the outside for later use.

[0035] According to the inner diameter of the cylindrical container o...

Embodiment 3

[0038] One side of the stainless steel mesh belt is sprayed with a cobalt-based catalyst capable of growing carbon nanotubes, and after heat treatment, it is placed in a reactor. A mixed gas containing 6% CO and 30% isopropanol was introduced, the temperature was 400° C., the pressure was 0.5 MPa, and the reaction time was 2 hours. After the carbon-containing process gas is cracked, a dense carbon nanotube array layer is formed on one side of the wire mesh belt; after the reaction is stopped, the stainless steel wire mesh belt with the carbon nanotube array layer is taken out. Four stainless steel wire mesh belts with carbon nanotube array layers are stacked to form a belt-like structure in which one side of the stainless steel mesh belt without carbon nanotubes is deposited and the other side with carbon nanotubes deposited at intervals. After bundling and fixing the belt-like structure, it is packed with filter cloth on the outside for later use.

[0039] According to the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com