High-efficiency energy-saving belt filter press

A belt filter press, high-efficiency and energy-saving technology, applied in filtration separation, mobile filter element filter, chemical industry, etc., can solve the problems of short service life, low work efficiency, poor dehydration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described.

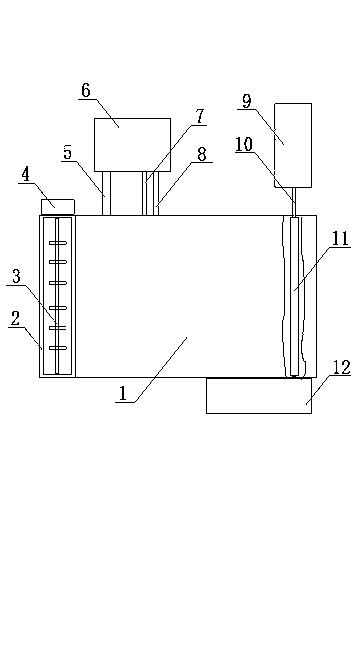

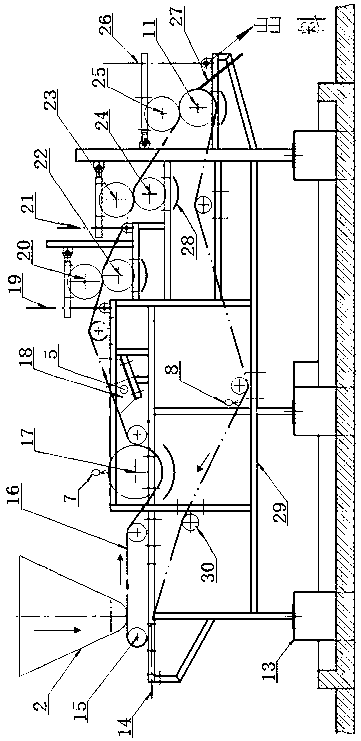

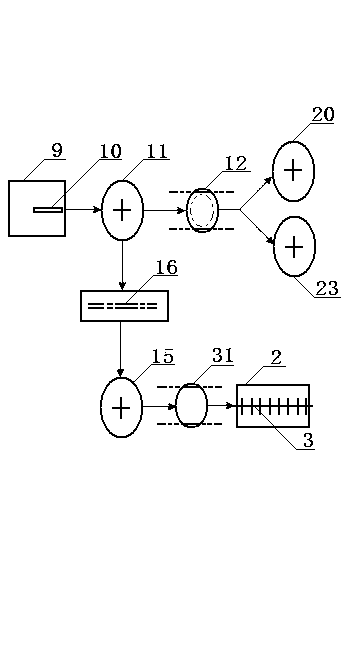

[0027] figure 1 Shown is a schematic structural view of the present invention; as can be seen from the figure, the present invention includes a filter press device 1, a hopper 2, a vacuum pump 6, a driving device 9 and a power transmission device 12 for rollers. Wherein, the hopper 2 is arranged at the rear end of the filter press device 1, that is, the feeding end; the bottom of the hopper 2 is provided with a stirring shaft 3, and one end of the stirring shaft 3 is powered by a hopper power transmission device 4 . Stirring shaft 3 is in rotation, stirs the slag material that enters the hopper 4, and distributes the slag material evenly to the top of the filter press belt. The vacuum pump 6 sends the vacuum air to the vacuum suction filter plate 18 located under the filter belt 16 through the vacuum tube 5, the exhaust pipe 7 of the mesh cage roller and the exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com