Negative pressure type ball mill coal grinding and powdering powder grinding system

A ball mill, negative pressure technology, applied in the field of negative pressure ball mill grinding coal powder grinding system, can solve the problems of power consumption, volume increase, large dust, etc., achieve small dust diffusion, provide efficiency, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

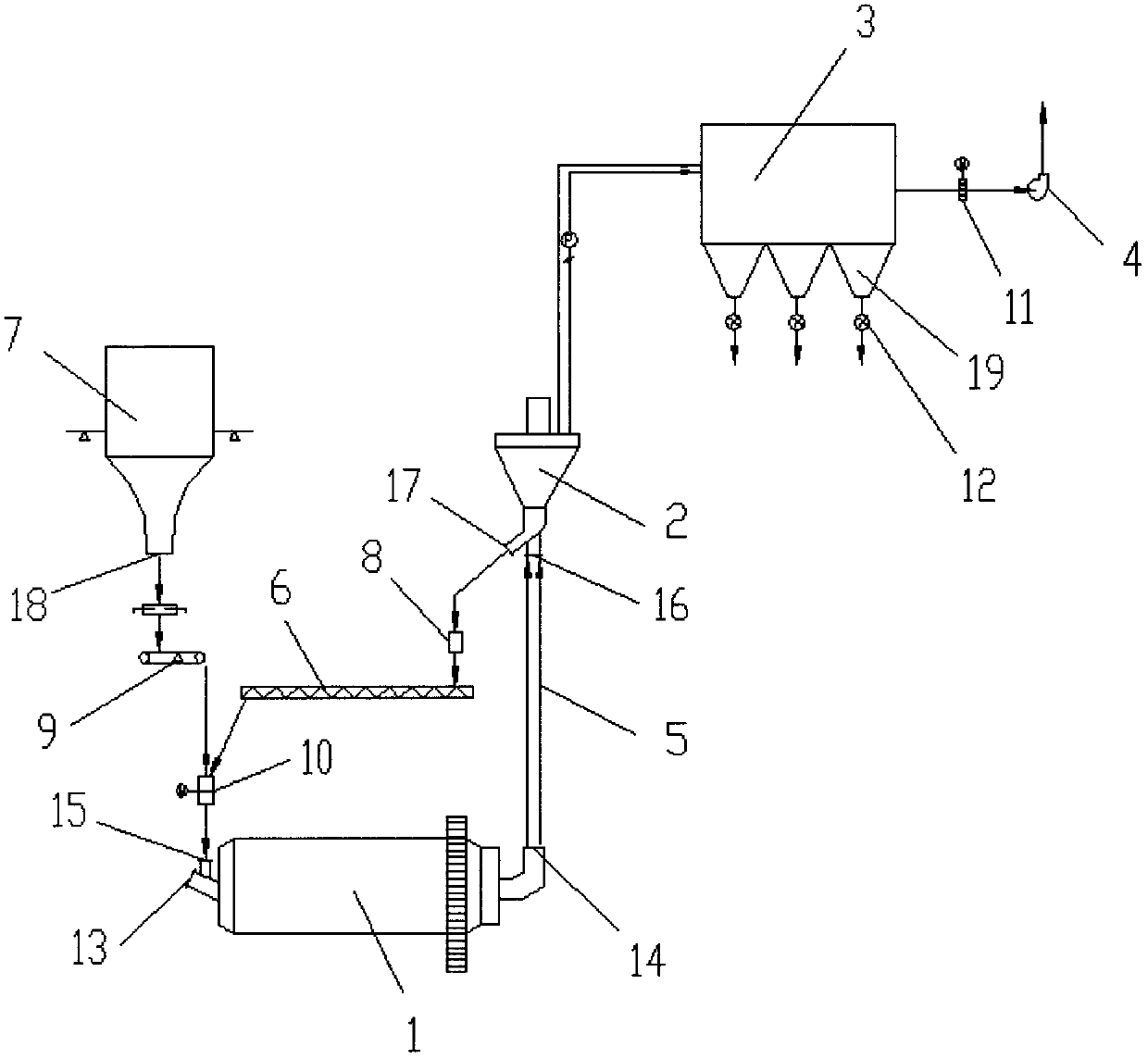

[0023] Please refer to figure 1 As shown, the embodiment of the present invention discloses a negative pressure ball mill grinding coal pulverization grinding system, which is specially aimed at the shortcomings of the coal grinding pulverization system in the prior art, and removes the hoist that has a greater impact on the grinding efficiency , on the basis of the original ball mill 1 as the main grinding equipment, the powder classifier 2, the bag filter 3 and the centrifugal fan 4 are connected in series to form a closed negative pressure supplemented by external fresh hot air. The dust-laden airflow open-loop production system, the air outlet 14 of the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com