Automatic chemical dosing jet flow mixing and water pump stirring sewage treatment system

A technology of sewage treatment system and automatic control system, which is applied in the direction of fluid mixer, mixer, mixer accessories, etc., can solve the problems of ineffective completion of polymer compounding and mixing, high manufacturing cost, long reaction time, etc. Complete functions, low power consumption and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

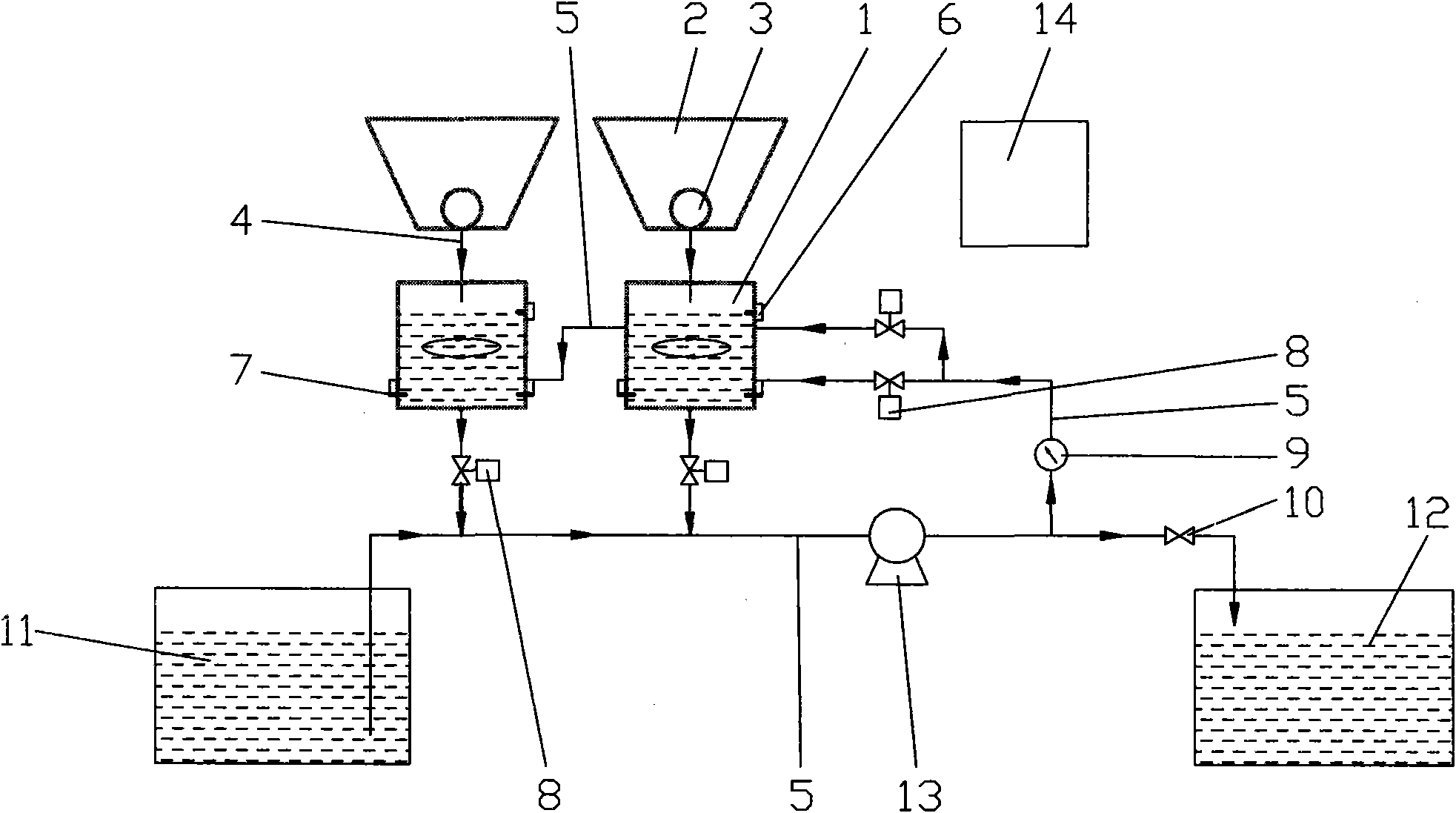

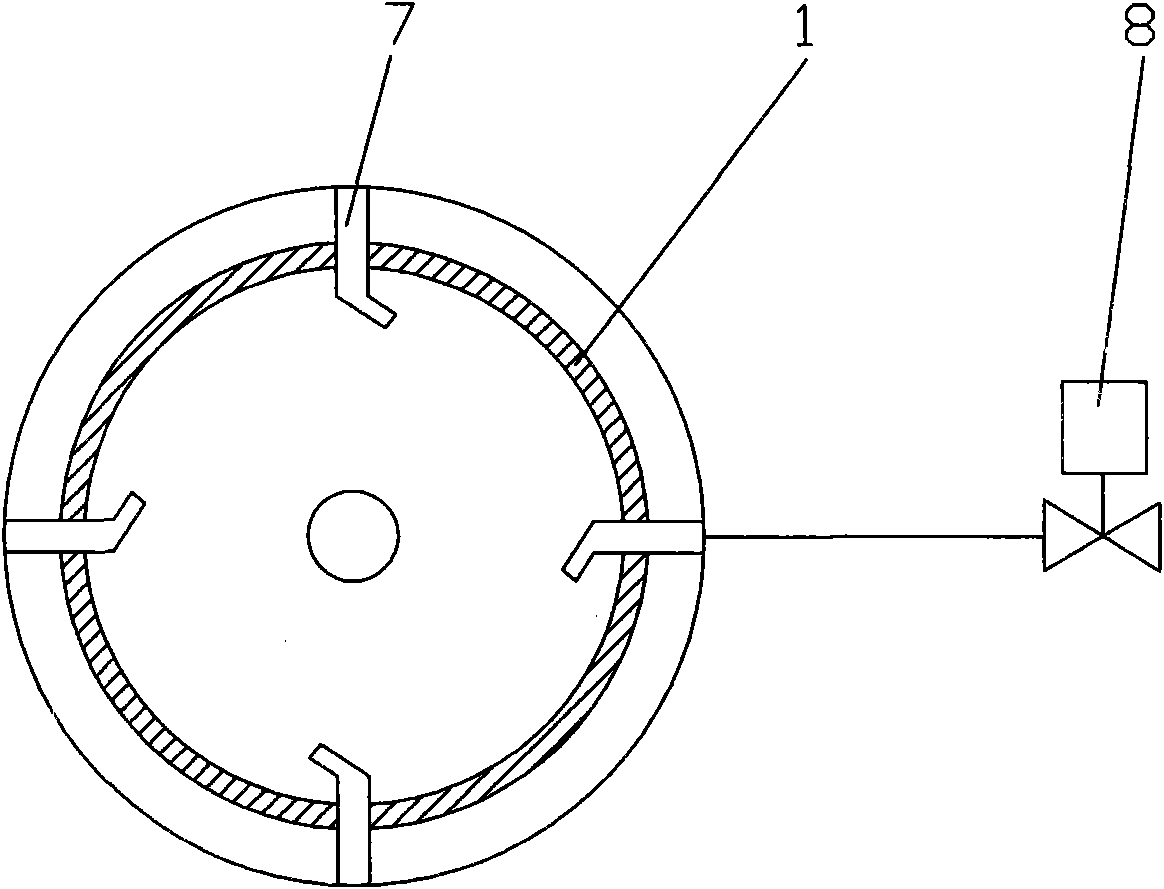

[0016] see figure 1 and figure 2 , an automatic dosing jet mixing and water pump agitation sewage treatment system, with a batching box 1, the batching box 1 is a single configuration or a combination of multiple single configurations in parallel, and the upper part of the batching box 1 is equipped with a drug storage of an automatic feeder 3 Box 2, the outlet 4 of the automatic feeder 3, communicates with the inner cavity of the batching box 1 through the pipeline 5; a liquid level detector 6 is installed on one side of the batching box 1, and the corresponding two At least two jet nozzles 7 are installed on the position, and the center line of the jet nozzle 7 and the center line of the batching box form a certain angle setting or elbow design; the jet nozzle 7 passes through the pipeline 5, the electric valve 8, the flow meter 9 It communicates with the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com