Mixer truck for concrete transport

A technology of mixer truck and concrete, which is applied in the direction of concrete transportation, cement mixing device, clay preparation device, etc., to achieve the effect of increasing bonding strength and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

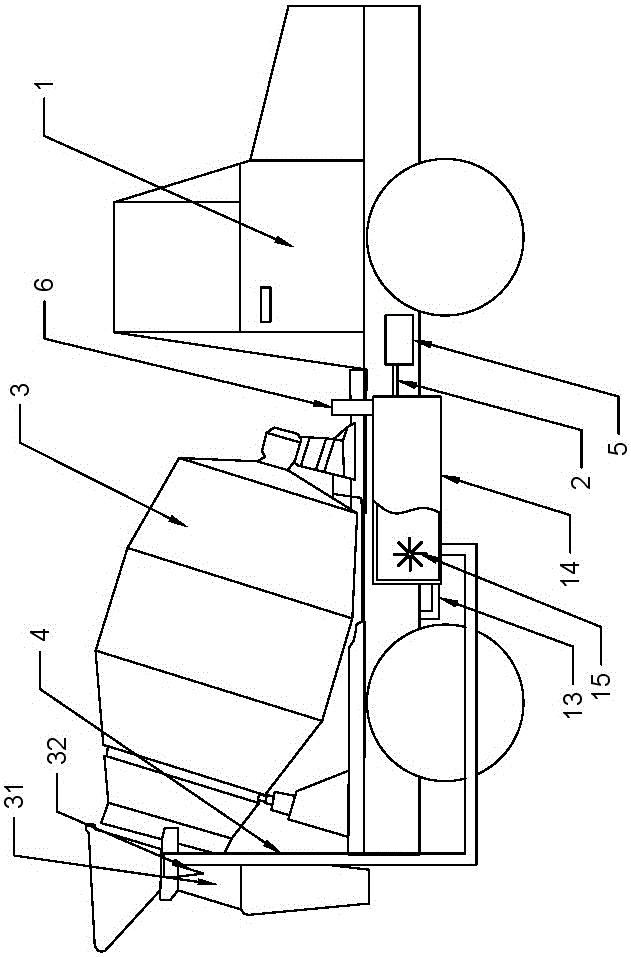

[0025] Basic as attached figure 1 Shown: a mixer truck used for concrete transportation, including a car body 1 and a mixing drum 3 . In fact, the better method of this program is to select an existing mixer truck and improve the existing mixer truck. This embodiment is to select an existing mixer truck whose emission standard has reached the national standard. If the national standard is reached, there are many impurities in the exhaust gas, which will dissolve into the water in the water tank 14, and eventually affect the quality of the concrete. The vehicle body 1 includes an exhaust pipe 12 , an air braking system 5 and a water tank 14 filled with water, and a discharge pipe 13 is arranged between the exhaust pipe 12 and the water tank 14 . What discharge pipe 13 was selected for use is a steel pipe, because the tail gas temperature discharged in the exhaust pipe 12 is still very high, if the insufficient high temperature resistant pipes such as rubber pipes and plastic p...

Embodiment 2

[0030] Compared with Embodiment 1, the only difference is that a selective catalytic reduction device is provided between the exhaust pipe 12 and the exhaust pipe 13 , and a particle trap is provided on the exhaust pipe 13 .

Embodiment 3

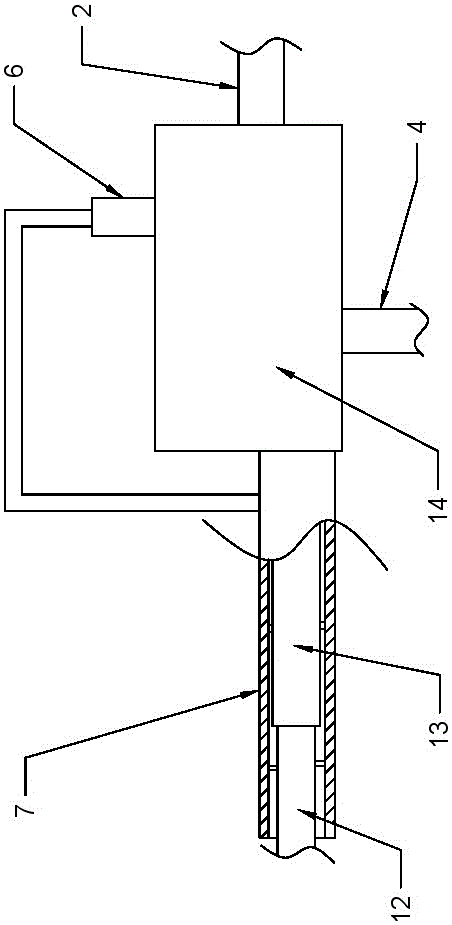

[0032] Compared with Embodiment 1, the only difference is that it also includes a cooling pipe 7, the cooling pipe 7 is sheathed on the exhaust pipe 12 and the discharge pipe 13, and supports are uniformly provided between the cooling pipe 7 and the exhaust pipe 12 and the discharge pipe 13 column, the cooling pipe 7 communicates with the outlet pipe 6, and the airflow direction between the cooling pipe 7 and the exhaust pipe 12 and the discharge pipe 13 is opposite to the airflow direction in the exhaust pipe 12 (as figure 2 shown). The high temperature of the exhaust gas will gradually heat up the water in the water tank 14. When the gas in the water tank 14 is discharged, it will carry a part of the steam. The steam will take away heat during the evaporation process, so it enters the cooling pipe 7 The temperature of the gas will be lower than the temperature in the tail gas pipe 12, and the cooling pipe 7 can initially cool the tail gas pipe 12 to prevent the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com