Post-treatment method for washing, drying and calcining SAPO (silicoaluminophosphate) molecular sieve

A molecular sieve and drying technology, applied in the direction of molecular sieve catalyst, molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc. The effect of dust pollution and low comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

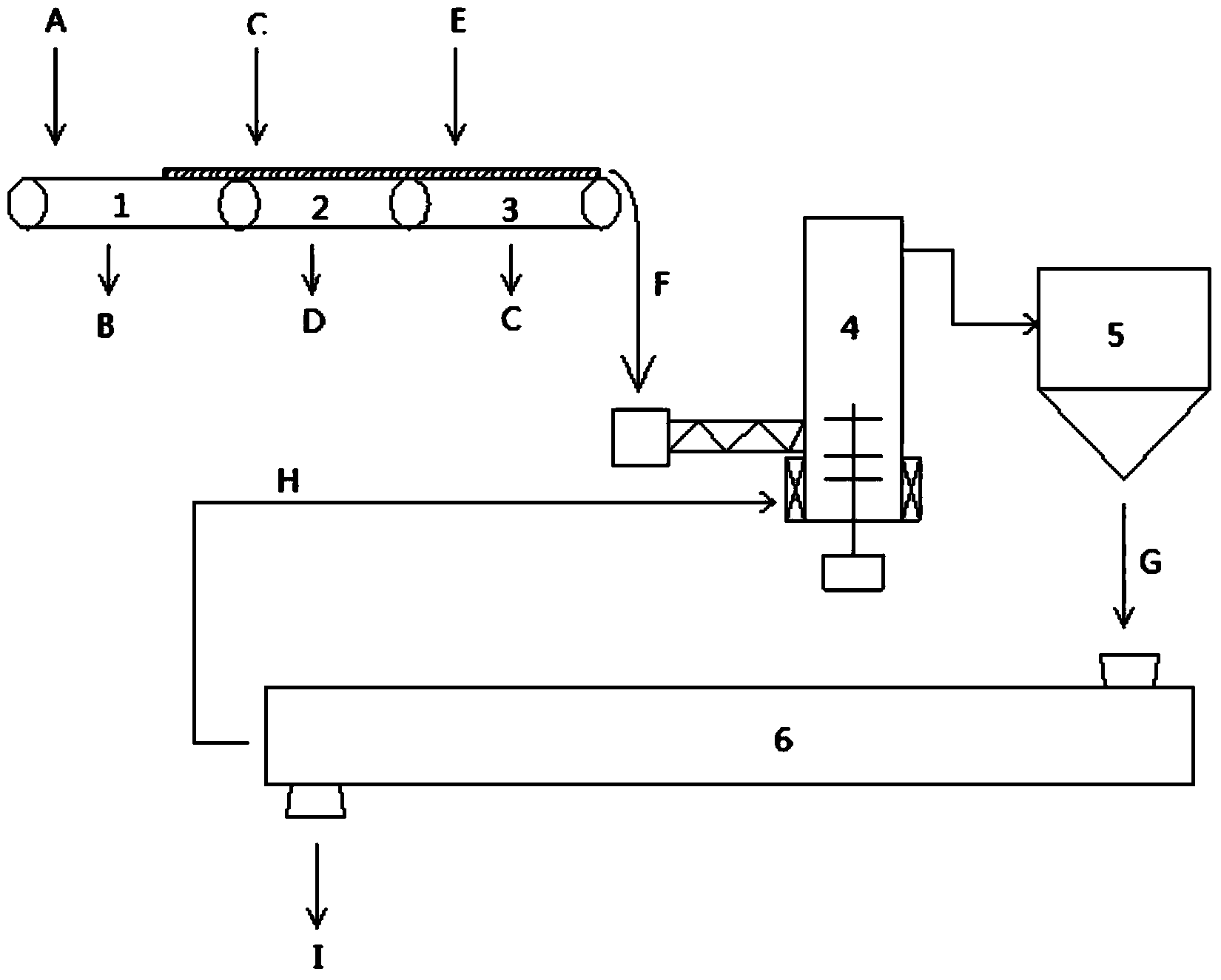

[0023] The SAPO molecular sieve mother liquor A of 500Kg after the crystallization is first filtered with a belt filter section 1, and the mother liquor B is separated, and then washed twice at the second section 2 of the belt filter and the third section 3 of the belt filter. The third section 3 of the belt filter is washed with desalted water E, and the obtained secondary washing liquid C is returned to the second section 2 of the belt filter for washing, and the primary washing liquid is filtered to achieve the purpose of recycling, and finally in the belt filter The filter cake F is formed at the end of the machine; then the filter cake F is dried at 400°C using the rotary flash drying device 4 to form a dry molecular sieve fine powder G with a particle size of 6-12 microns; the dry molecular sieve fine powder G passes through a bag filter 5 After collection, use the rotary kiln 6 to roast the molecular sieve fine powder G. The roasting temperature is 550°C, the roasting ti...

Embodiment 2

[0025] The SAPO molecular sieve mother liquor A of 1200Kg after the crystallization is first filtered with a belt filter section 1, and the mother liquor B is separated, and then washed twice in the second section 2 of the belt filter and the third section 3 of the belt filter. The third section 3 of the belt filter is washed with desalted water E, and the obtained secondary washing liquid C is returned to the second section 2 of the belt filter for washing, and the primary washing liquid is filtered to achieve the purpose of recycling, and finally in the belt filter The filter cake F is formed at the end of the machine; then the filter cake F is dried at 600°C using the rotary flash drying device 4 to form a dry molecular sieve fine powder G with a particle size of 8-13 microns; the dry molecular sieve fine powder G passes through a bag filter 5 After collection, use the rotary kiln 6 to roast the molecular sieve fine powder G. The roasting temperature is 700°C, the roasting t...

Embodiment 3

[0027] The SAPO molecular sieve mother liquor A of 800Kg after crystallization is first filtered with belt filter one section 1, and mother liquor B is separated, and then washed twice at belt filter two section 2 and belt filter three section 3, wherein The third section 3 of the belt filter is washed with desalted water E, and the obtained secondary washing liquid C is returned to the second section 2 of the belt filter for washing, and the primary washing liquid is filtered to achieve the purpose of recycling, and finally in the belt filter The filter cake F is formed at the end of the machine; then the filter cake F is dried at 500°C using a rotary flash drying device 4 to form a dry molecular sieve fine powder G with a particle size of 2-16 microns; the dry molecular sieve fine powder G passes through a bag filter 5 After collection, use the rotary kiln 6 to roast the molecular sieve fine powder G. The roasting temperature is 620°C, the roasting time is 5 hours, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com