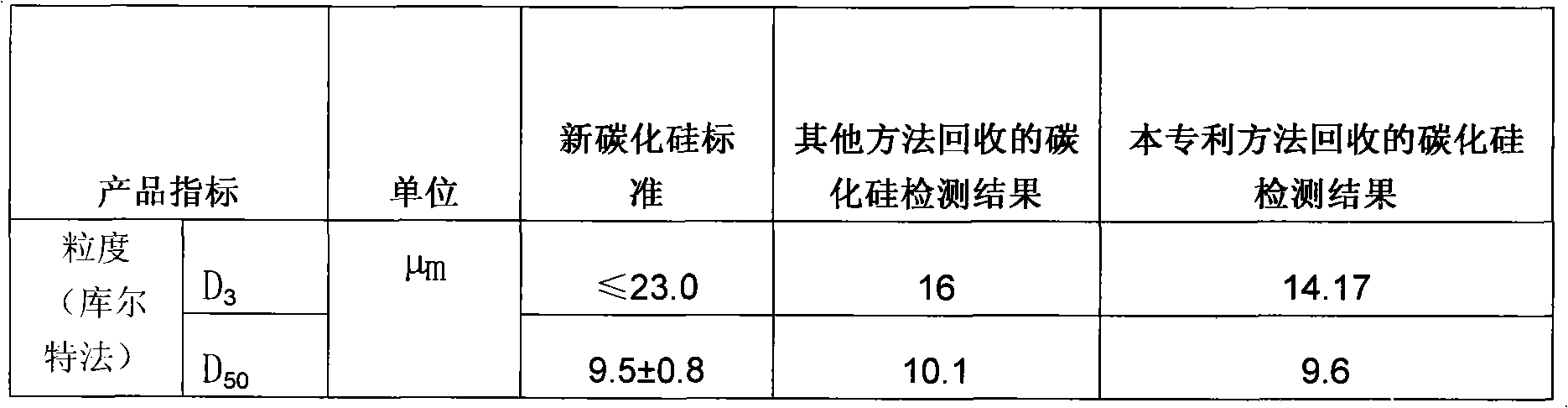

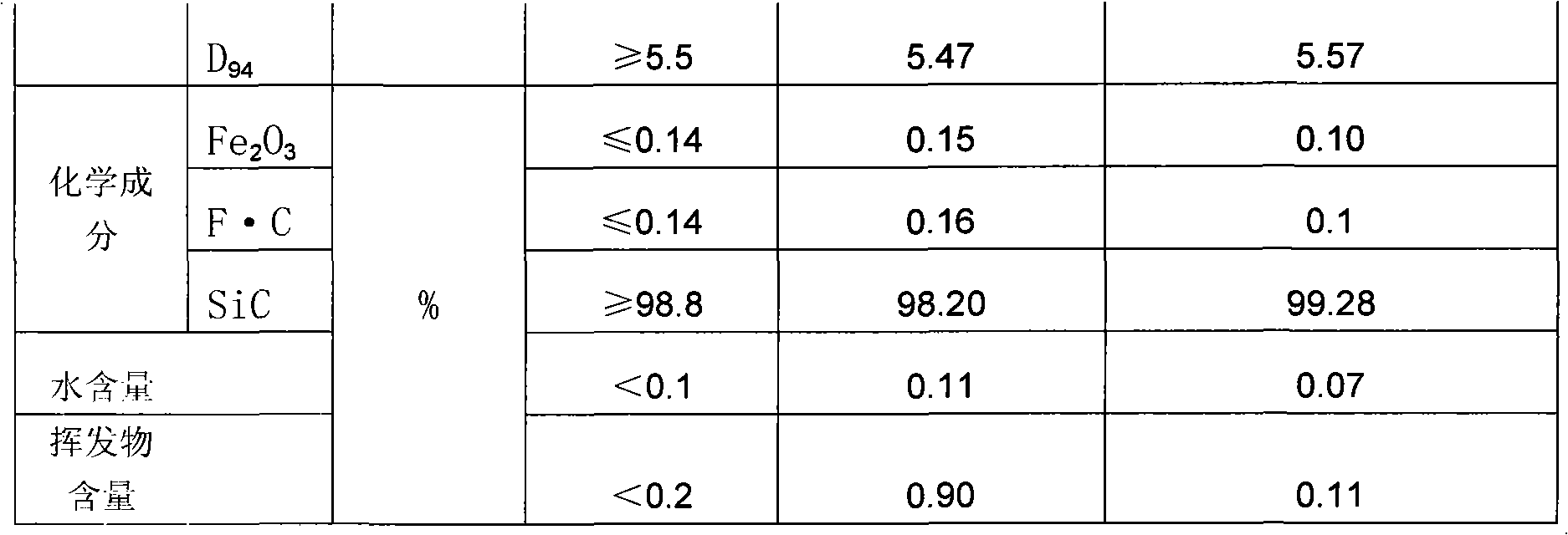

Method for recovering silicon carbide and polyglycol cutting solution from silicon slice cutting waste mortar

A technology of silicon wafer cutting and polyethylene glycol, applied in the direction of lubricating compositions, etc., can solve the problems of low recovery rate, aggravated environmental burden, large amount of waste water, etc., achieve less water and volatile matter content, improve cutting efficiency, and reduce particle size distribution concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

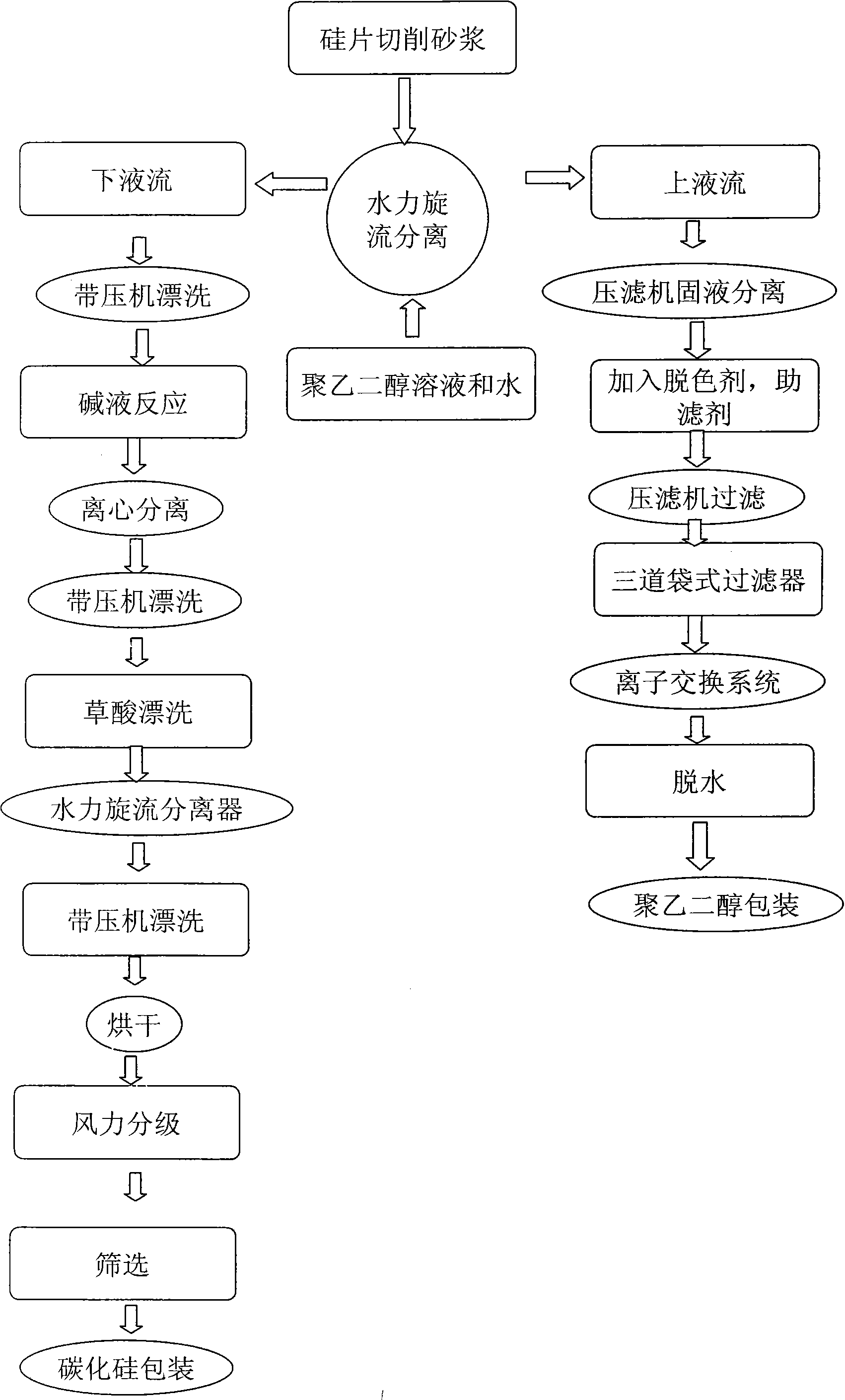

Method used

Image

Examples

Embodiment 1

[0043] The method for reclaiming silicon carbide and polyethylene glycol cutting fluid from silicon chip cutting waste mortar of the present embodiment comprises the following steps:

[0044] Stir the silicon wafer cutting waste mortar evenly with a stirrer at room temperature, add 1% polyethylene glycol solution and water, control its temperature at 25°C, put it into a six-stage hydrocyclone separator, and keep the pressure at 0.5bar; under this pressure, the cyclone separator separates to obtain upper liquid flow and lower liquid flow: the lower liquid flow contains most of the silicon carbide larger than 5um; the upper liquid flow contains most of the silicon, a large amount Moisture, silicon carbide less than 5um;

[0045] The liquid flow obtained by the hydrocyclone separator is poured into a vacuum belt filter for filtration, cleaned with clean water to remove impurities on the surface of silicon carbide, and vacuumed to absorb water to obtain a filter cake with a moistu...

Embodiment 2

[0053] The method for reclaiming silicon carbide and polyethylene glycol cutting fluid from silicon chip cutting waste mortar of the present embodiment comprises the following steps:

[0054] Stir the silicon chip cutting waste mortar evenly with a stirrer at room temperature, add polyethylene glycol solution and water with a content of 35%, control its temperature at 65°C, put it into a six-stage hydrocyclone separator, and keep the pressure at 3bar; under this pressure, the cyclone separator is separated to obtain the upper liquid flow and the lower liquid flow: the lower liquid flow contains most of the silicon carbide larger than 5um; the upper liquid flow contains most of the silicon, a large amount of water , silicon carbide less than 5um;

[0055] The liquid flow obtained by the hydrocyclone separator is poured into a vacuum belt filter for filtration, cleaned with clean water to remove impurities on the surface of silicon carbide, and vacuumed to absorb water to obtain...

Embodiment 3

[0063] The method for reclaiming silicon carbide and polyethylene glycol cutting fluid from silicon chip cutting waste mortar of the present embodiment comprises the following steps:

[0064] Stir the silicon chip cutting waste mortar evenly with a stirrer at room temperature, add polyethylene glycol solution and water with a content of 25%, control its temperature at 50°C, put it into a six-stage hydrocyclone separator, and keep the pressure at 2bar; under this pressure, the cyclone separator is separated to obtain the upper liquid flow and the lower liquid flow: the lower liquid flow contains most of the silicon carbide larger than 5um; the upper liquid flow contains most of the silicon, a large amount of water , silicon carbide less than 5um;

[0065] The liquid flow obtained by the hydrocyclone separator is poured into the vacuum belt filter for filtration, and the impurities on the surface of the silicon carbide are removed by washing with clean water, and the water is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com