High-efficiency desulfurization dust separation system for coal-fired boiler flue gas

A technology for desulfurization and dust removal and coal-fired boilers, applied in chemical instruments and methods, use of liquid separating agents, lighting and heating equipment, etc., can solve problems such as poor desulfurization and dust removal effects, achieve the effect of eliminating secondary pollution and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

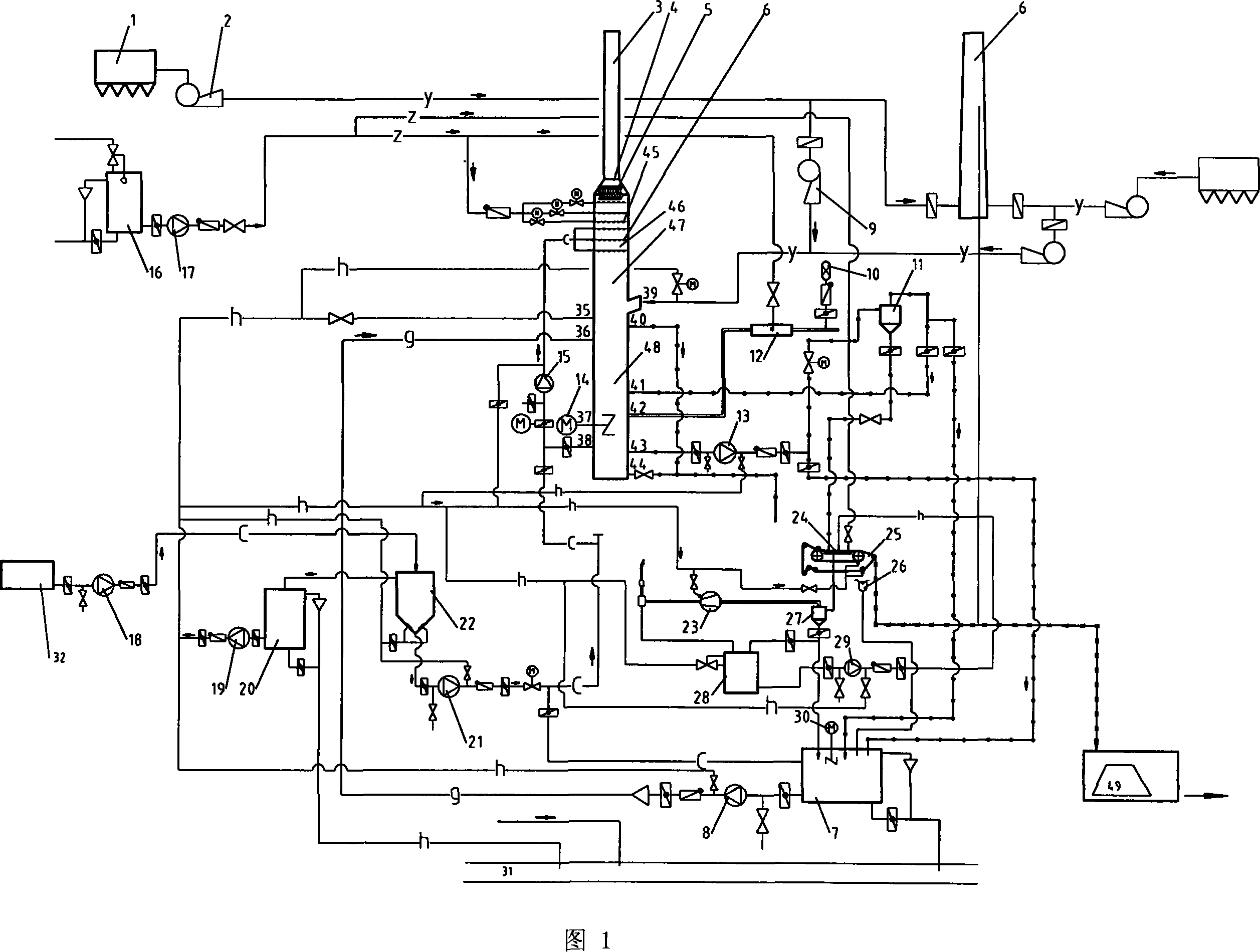

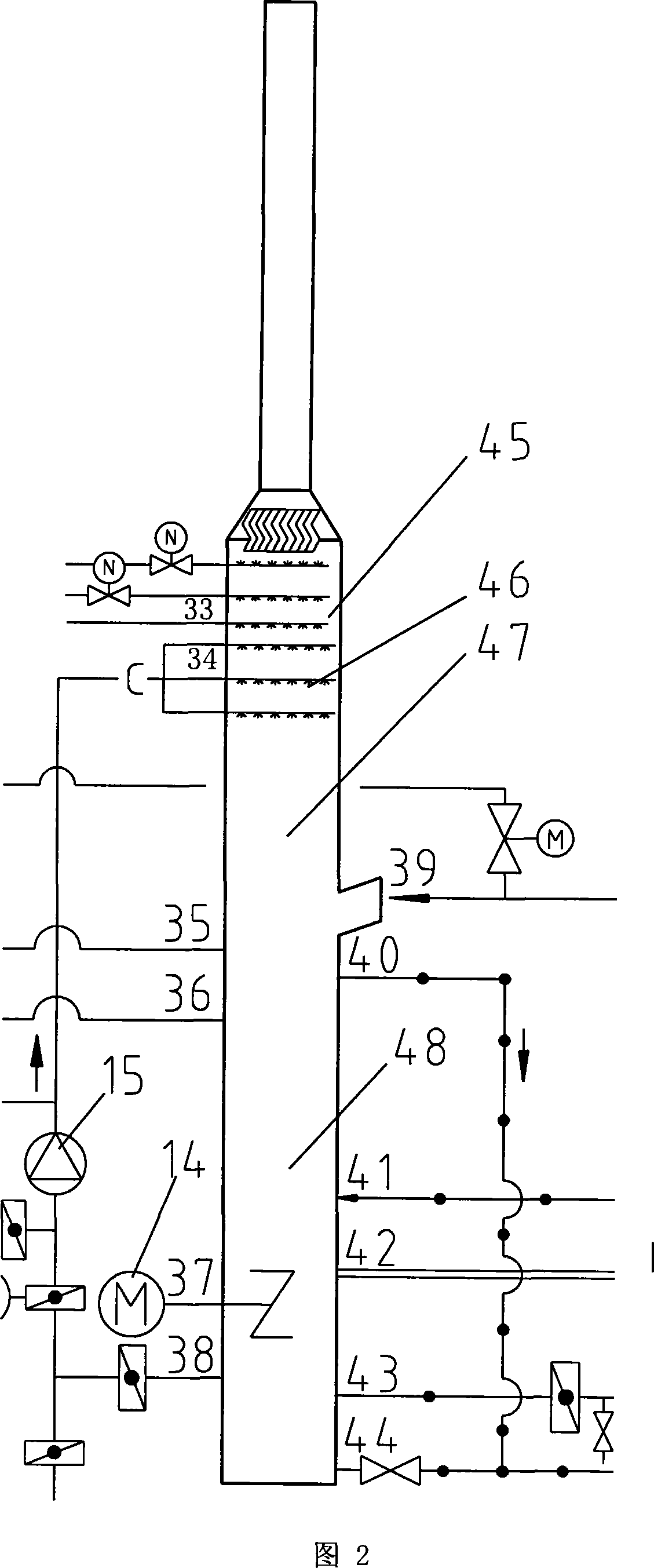

[0013] Referring to Figures 1 and 2, the embodiment of the present invention is provided with a dust collector 1, an induced draft fan 2, a booster fan 9, an absorption tower 4, a process water pump 17, a process water tank 16, an oxidation fan 10, a hydrocyclone 11, and a slurry discharge pump 13. The first agitator 14, the second agitator 30, circulation pump 15, slurry delivery pump 18, clear water pump 19, clear water tank 20, emulsion pump 21, concentration tank 22, water ring vacuum pump 23, mixing tank 24, belt Type filter press 25, filtrate tank 26, gas-water separator 27, filter cloth washing pump 29, filter cloth washing water tank 28, filtrate neutralization tank 7, filtrate water pump 8, and electric butterfly valve, solenoid valve, shut-off valve, regulating valve , inlet baffle door, check valve, piping, etc.

[0014] Under the action of the induced draft fan 2, the flue gas discharged from the exhaust outlet of the dust collector 1 enters the flue gas chamber 47...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com