Extremely wide type breadth shortening forming cutting machine

A technology of shearing machine and sizing machine, which is applied in the cutting of textile materials, textiles and papermaking, and winding strips, etc. It can solve the problems of unmatched sizing machines, low efficiency, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

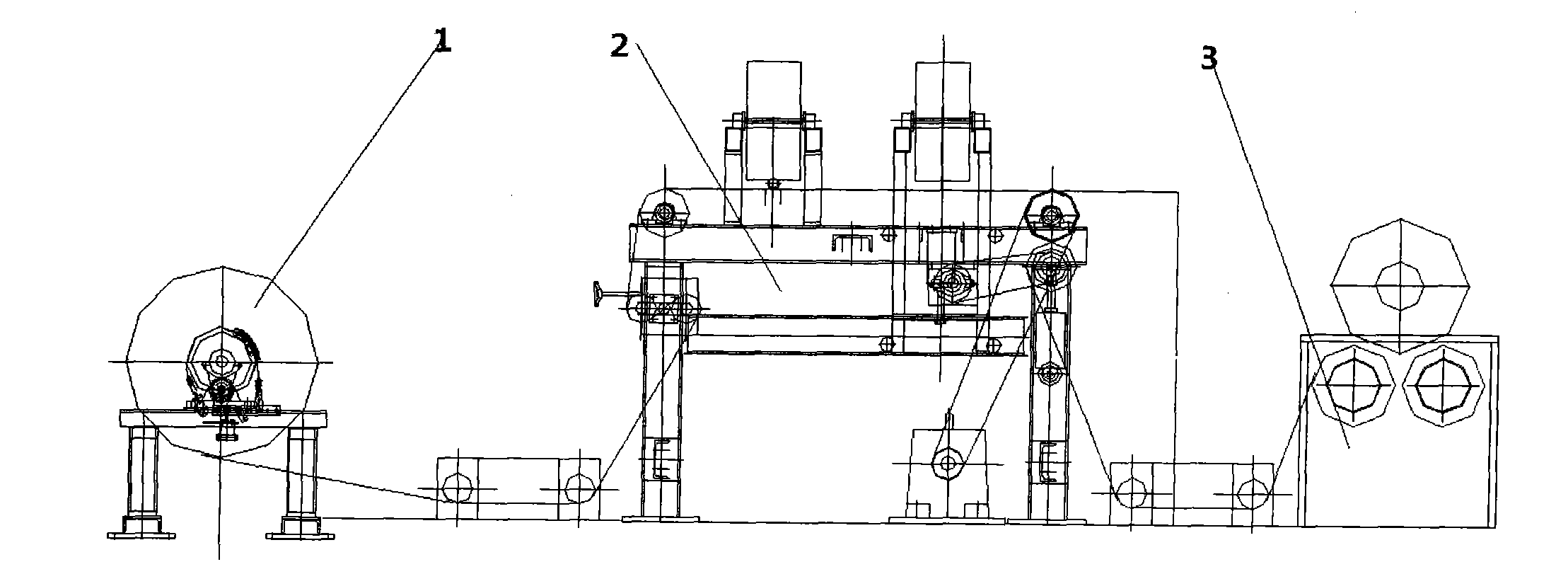

[0012] Such as figure 1 As shown, the overall structure of the ultra-wide shrinking and shaping shearing machine is composed of a shaft frame assembly 1, a shearing assembly 2, and a winding assembly 3.

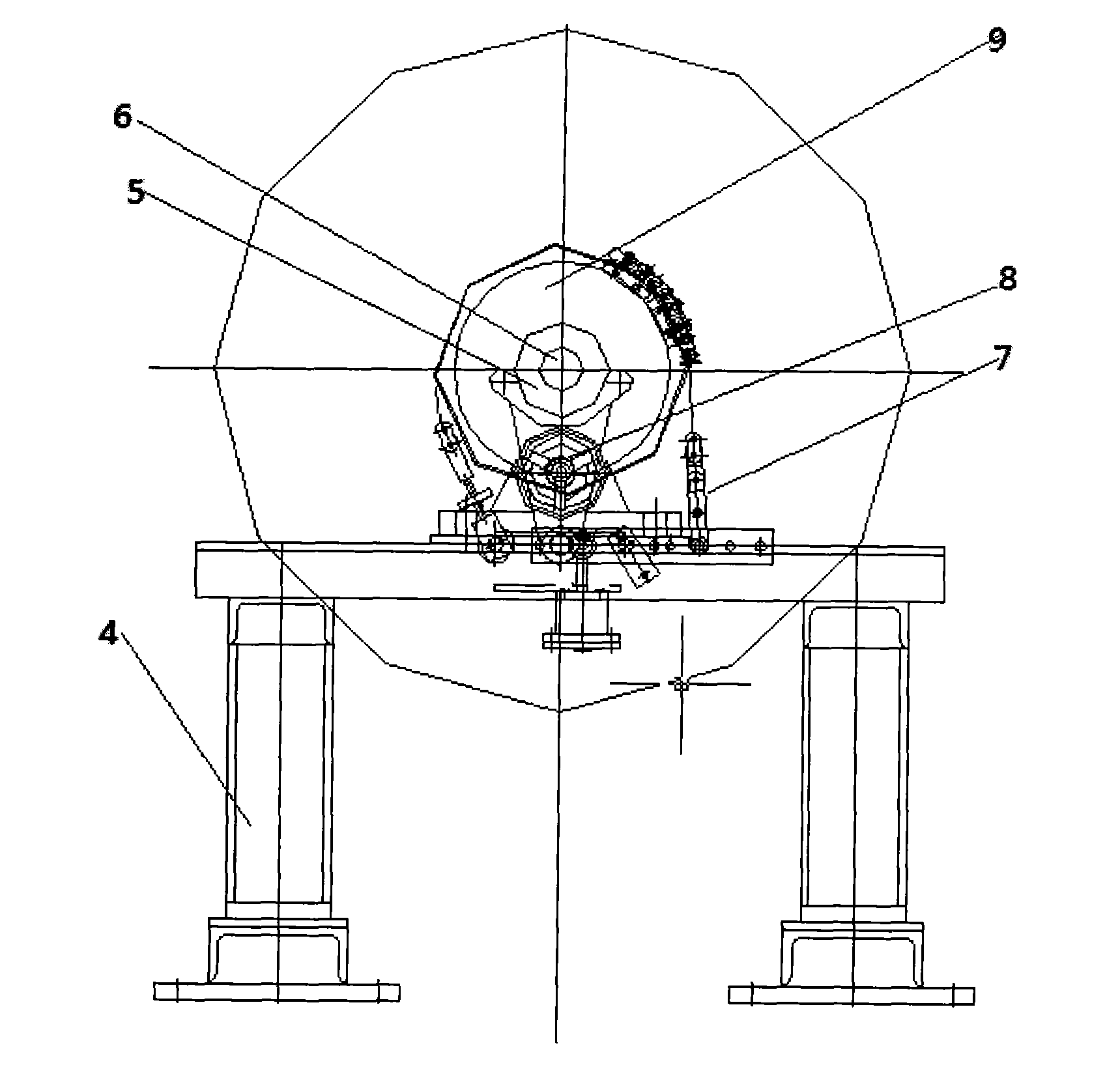

[0013] The shaft frame assembly is composed of a shaft frame 4, a bearing 5, a reel 6, a braking device 7, an adjustment hand wheel 8, and a cloth roll 9. Both ends of the shaft frame can be fine-tuned axially, and the position of the shaft frame bracket along the axial It can be adjusted to suit different widths. The channel steel adjusted along the axial position of the shaft bracket is level with the ground. The tension is pneumatically controlled, the pressure is manually adjusted, and the brake is braked by the brake band.

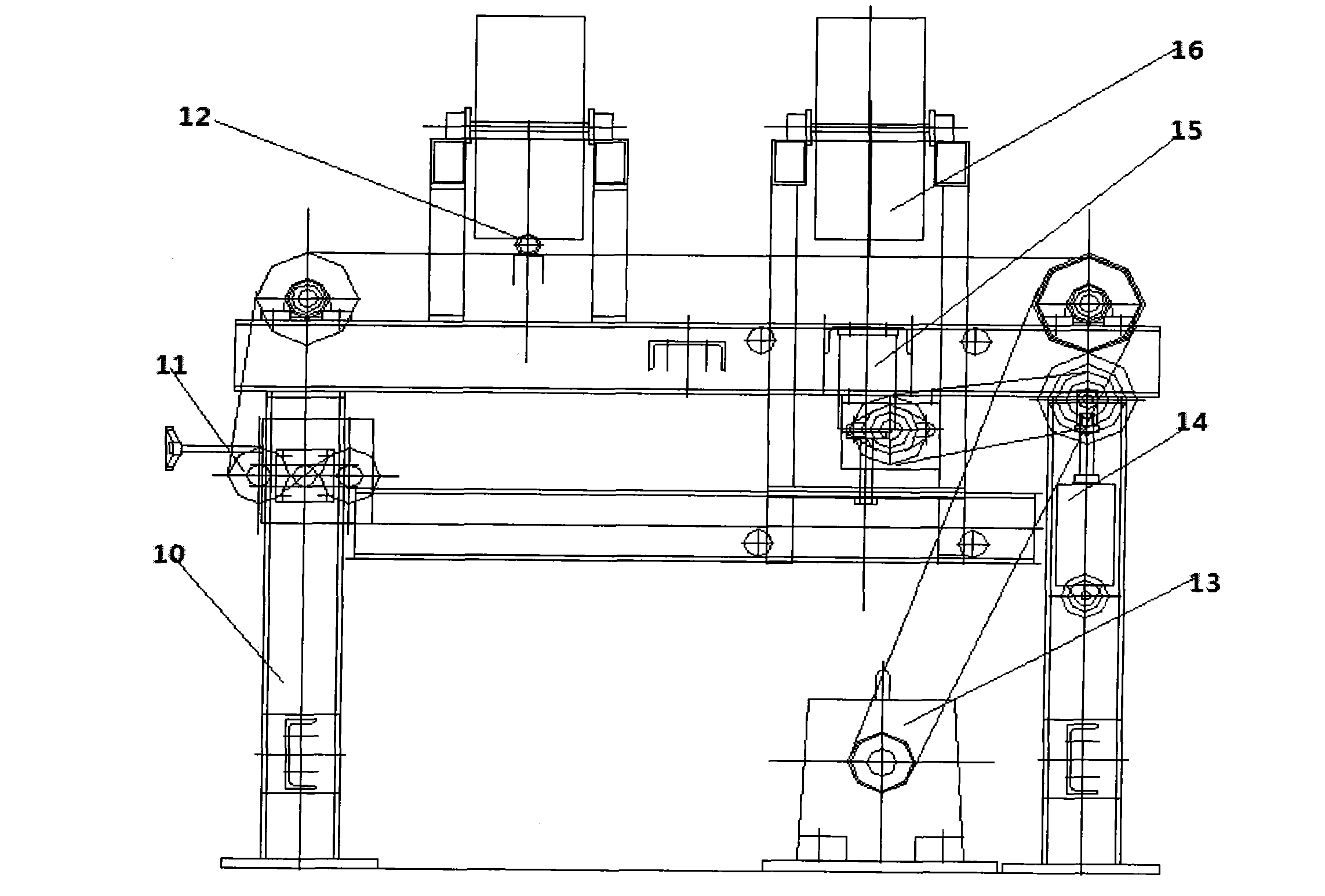

[0014] The shearing assembly is composed of a bracket part 10, a cloth tight frame part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com