Tobacco Treatment

a technology for tobacco and tobacco products, applied in the field of tobacco treatment, can solve the problems of difficult to maintain turbulent mixing at the edges of the vessel, not without their disadvantages, and the throughput of such extraction and separation processes is clearly limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

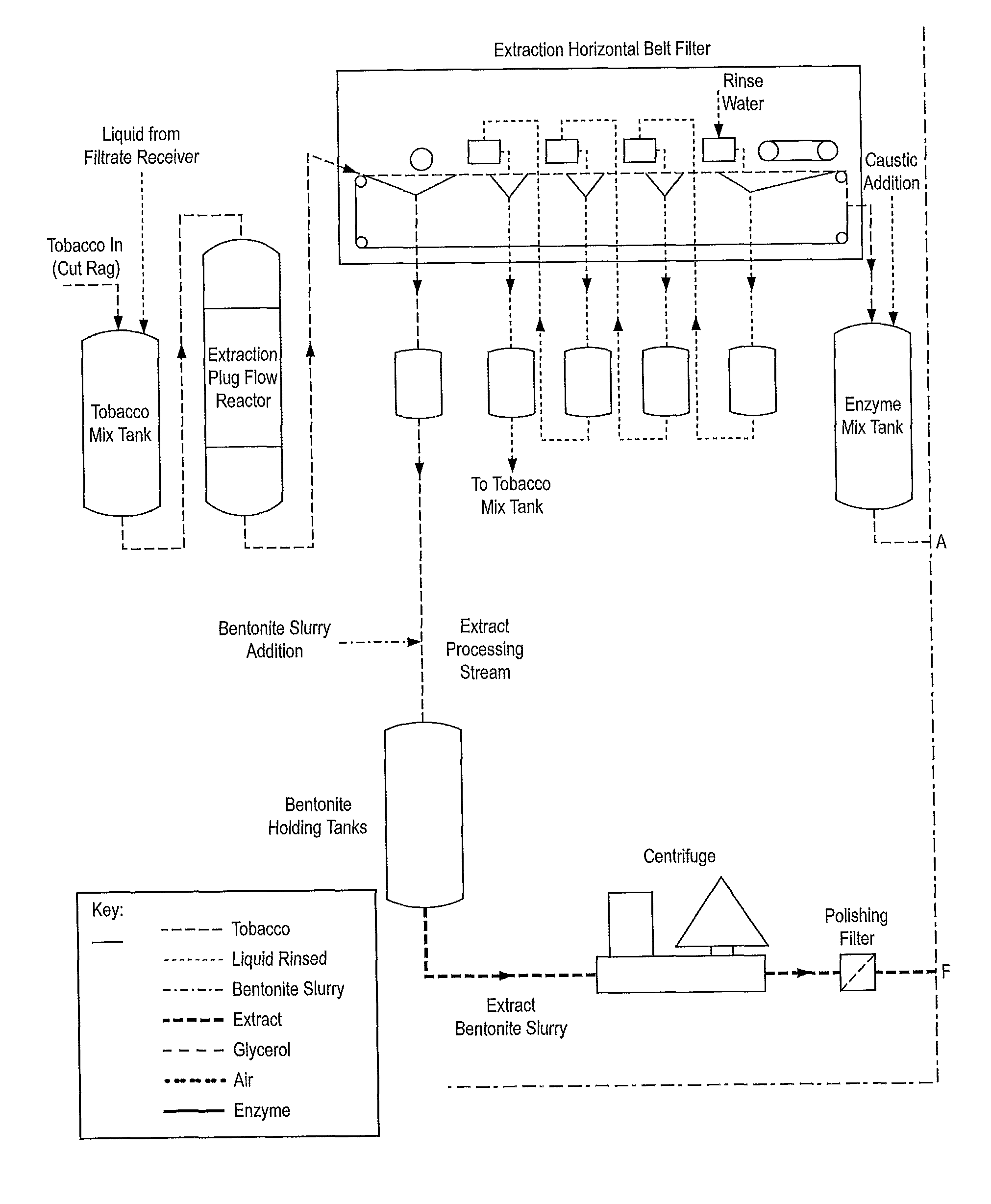

[0040]In one embodiment of this invention, the tobacco material to be extracted is strip, cut, shredded or ground tobacco. In a preferred embodiment, the tobacco is shredded tobacco. Other forms of tobacco may, however, be extracted using the methods described herein.

[0041]The tobacco material may be mixed with a solvent for extraction to form a slurry. The solvent may be added to the tobacco material in a ratio of between 10:1 and 50:1, preferably between 20:1 and 40:1 and most preferably between 25:1 and 30:1 by weight. In a particularly preferred embodiment, the solvent is added to the tobacco material in a ratio of 27:1 by weight.

[0042]The solvent may be an organic solution, but preferably is an aqueous solution or is water. At the very start of the extraction process, the solvent is usually water, but it can also contain alcohols such as ethanol or methanol, or it can contain a surfactant. Other solvents could be used, depending on the particular constituents to be extracted fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com