Bearing lubricating and cooling method and device

A lubricating cooling and bearing lubricating technology, which is applied in the direction of bearing cooling, engine lubrication, bearing components, etc., can solve the problems that the efficiency of the rolling mill cannot be fully exerted, and achieve the effect of improving the cooling effect and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

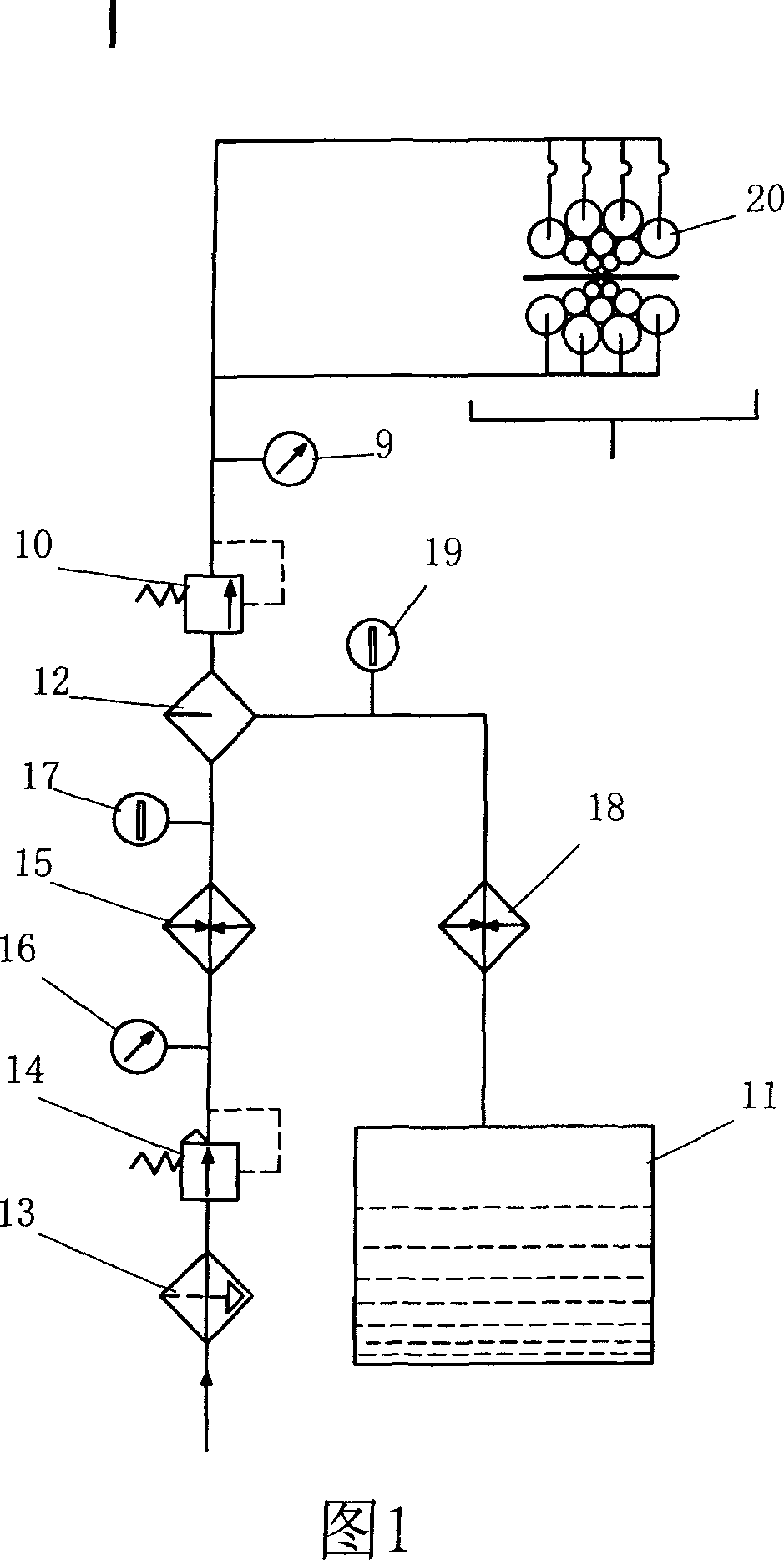

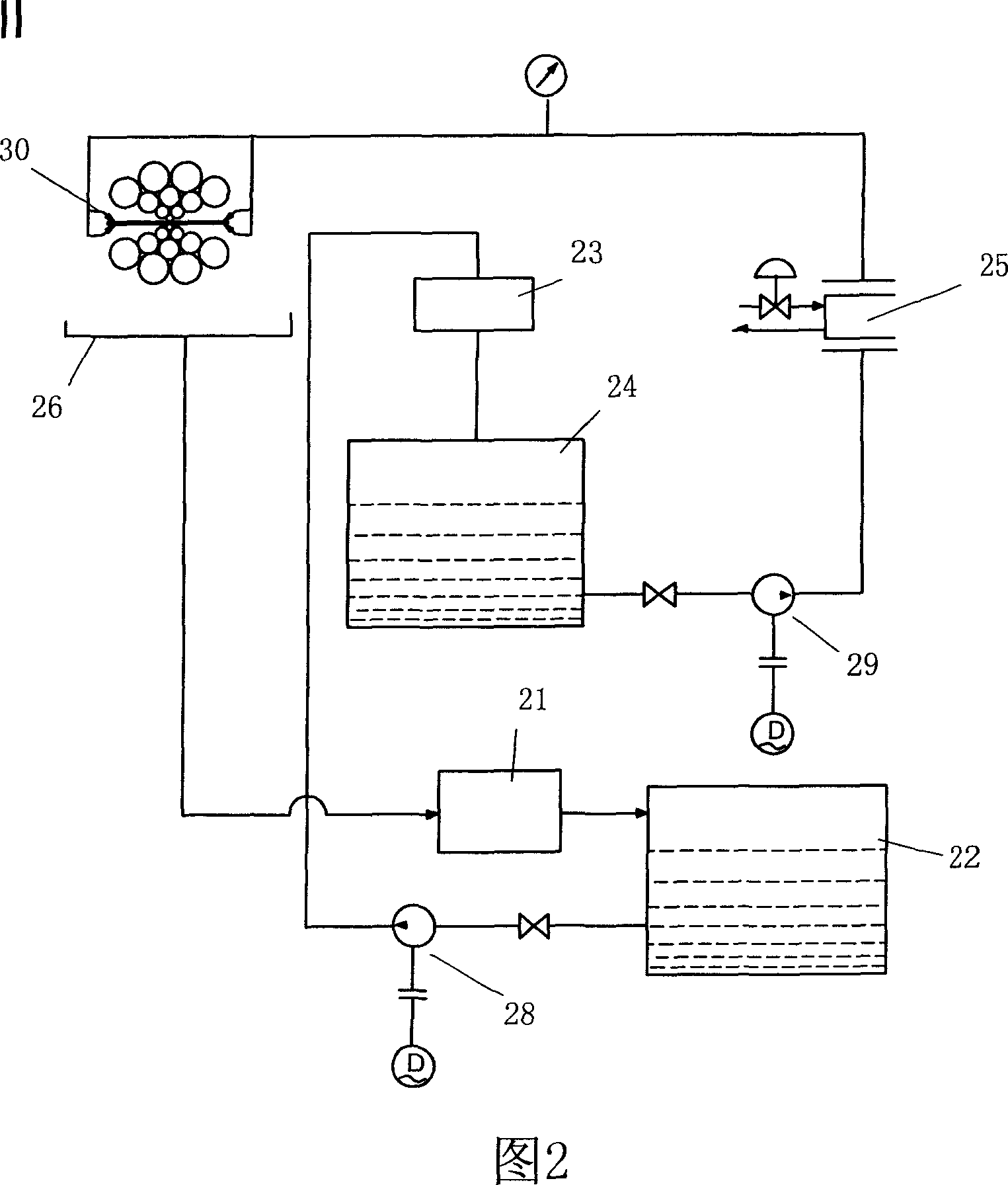

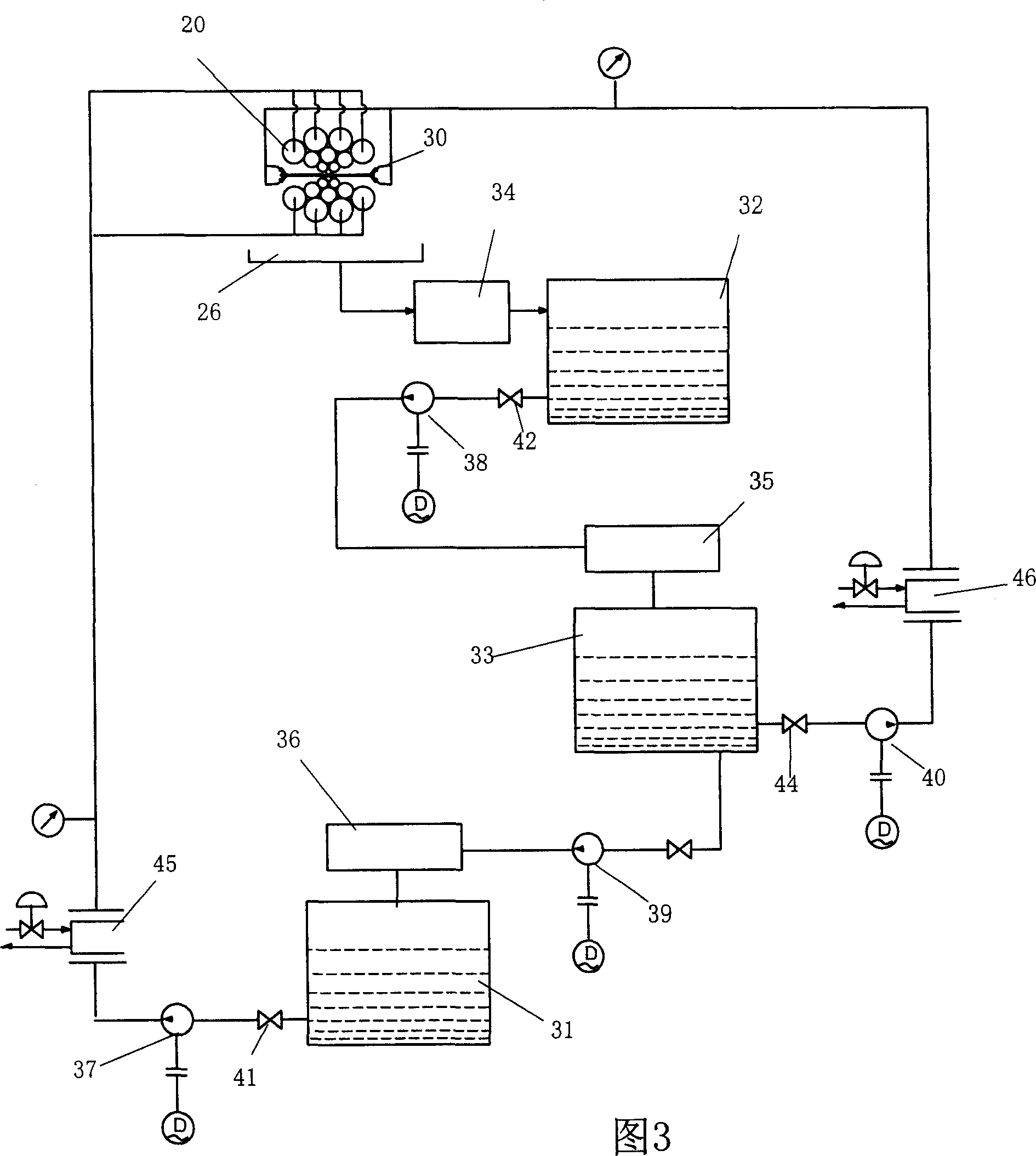

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a rolling and backing bearing method using a medium cooling and lubricating rolling mill process. Since one medium is used, there is no problem that the lubricating and cooling effect is reduced due to the mixing of different lubricating mediums.

[0030] The lubricating and cooling method of the bearing provided by the present invention is to use the emulsion as the medium for lubricating and cooling; the emulsion circulation device is used to supply the liquid to the backing bearing, the roll and the plate to be rolled. The emulsion used is an anti-rust emulsion with good lubricity and super cooling capacity. The kinematic viscosity of the rolling oil (at 40°C): 40-70mm 2 / s, preferably 60mm 2 / s; saponification value=(11 0~190) mgKOH / g, preferably 150 mgKOH / g; oil content in the emulsion > 1%, preferably 3%. Specifically, select the QUAKEROL emulsion of the U.S. Quake (QUAKER) company, preferably QUAKEROLC77-XD, QUAKEROL C79-XD and RO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com