C30-grade all-solid-waste concrete and preparation method thereof

A waste concrete and carbide slag technology, applied in the field of building materials, can solve the problems of limited application, insufficient concrete strength, low strength, etc., and achieve the effects of reducing production costs, reducing excessive mining of stone materials, and reducing high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the all-solid waste concrete of the present invention can be a general concrete preparation method, but the relevant raw materials are replaced with the alkali slag-carbide slag, slag, fly ash, and iron tailing sandstone of the present invention. But in order to be able to achieve better strength, it is preferably prepared by the following steps:

[0035] S1. Put the alkali slag and the carbide slag stock solution into static stratification to obtain the upper clear liquid and the lower slurry of the alkali slag and the carbide slag respectively, and store the upper clear liquid and the lower slurry separately for later use; the upper clear liquid of the calcium carbide slag, its OH - The concentration is 0.032-0.063mol / L, the pH value is 12.5-12.8; the moisture content of the slurry in the lower part of the alkali slag and carbide slag is 50%-60%.

[0036] S2. Pretreat the lower slurry of alkali slag and carbide slag, dry it naturally, crush i...

Embodiment 1

[0041] Alkali slag, carbide slag, slag, fly ash, iron tailings, iron tailings, water reducing agent by weight: 52-156 parts of alkali slag, 26-78 parts of calcium carbide slag, 182-234 parts of slag , 104-208 parts of fly ash, 170-190 parts of water, 460-510 parts of iron tailings, 1030-1150 parts of iron tailings, 1-3 parts of polycarboxylate superplasticizer.

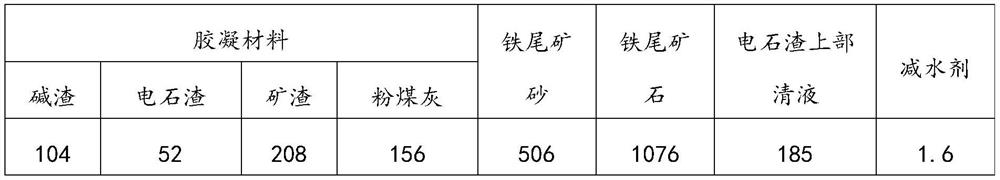

[0042] The specific mixing ratio of all solid waste concrete is shown in the following table: (Concrete material consumption per cubic meter: kg / m 3 ):

[0043]

[0044] According to the above mixing ratio, the specific preparation steps are as follows:

[0045] S1. Put the alkali slag and the carbide slag stock solution into static stratification to obtain the upper clear liquid and the lower slurry of the alkali slag and the carbide slag respectively, and store the upper clear liquid and the lower slurry separately for later use;

[0046] S2. Pretreat the lower slurry of alkali slag and carbide slag, dry it nat...

Embodiment 2

[0076] Alkali slag, carbide slag, slag, fly ash, iron tailings, iron tailings, water reducing agent by weight: 52-156 parts of alkali slag, 26-78 parts of calcium carbide slag, 182-234 parts of slag , 104-208 parts of fly ash, 170-190 parts of water, 460-510 parts of iron tailings, 1030-1150 parts of iron tailings, 1-3 parts of polycarboxylate superplasticizer.

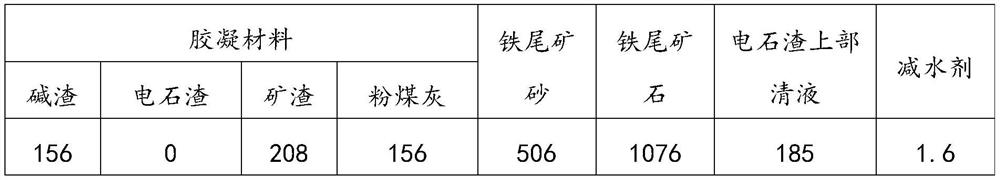

[0077] The specific mixing ratio of all solid waste concrete is shown in the following table: (Concrete material consumption per cubic meter: kg / m 3 ):

[0078]

[0079] According to the above mixing ratio, the specific preparation steps are as follows:

[0080] S1. Put the alkali slag and the carbide slag stock solution into static stratification to obtain the upper clear liquid and the lower slurry of the alkali slag and the carbide slag respectively, and store the upper clear liquid and the lower slurry separately for later use;

[0081]S2. Pretreat the lower slurry of alkali slag and carbide slag, dry it natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com