Process for preparing composition 'Sailong' from industrial waste dregs by in-situ synthesis

An industrial waste, in-situ technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of limited heating area, limited research level, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

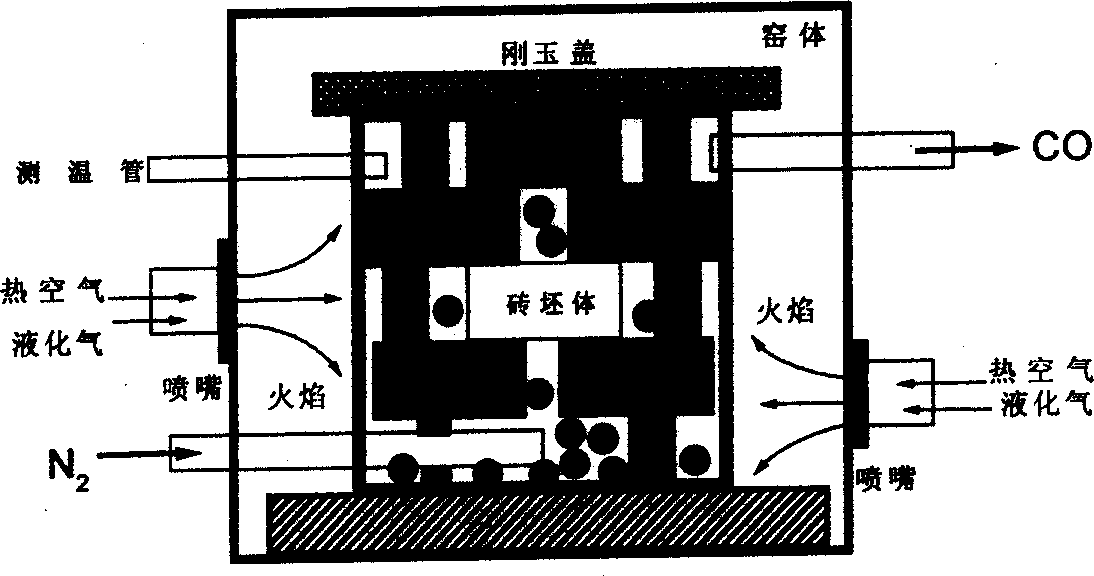

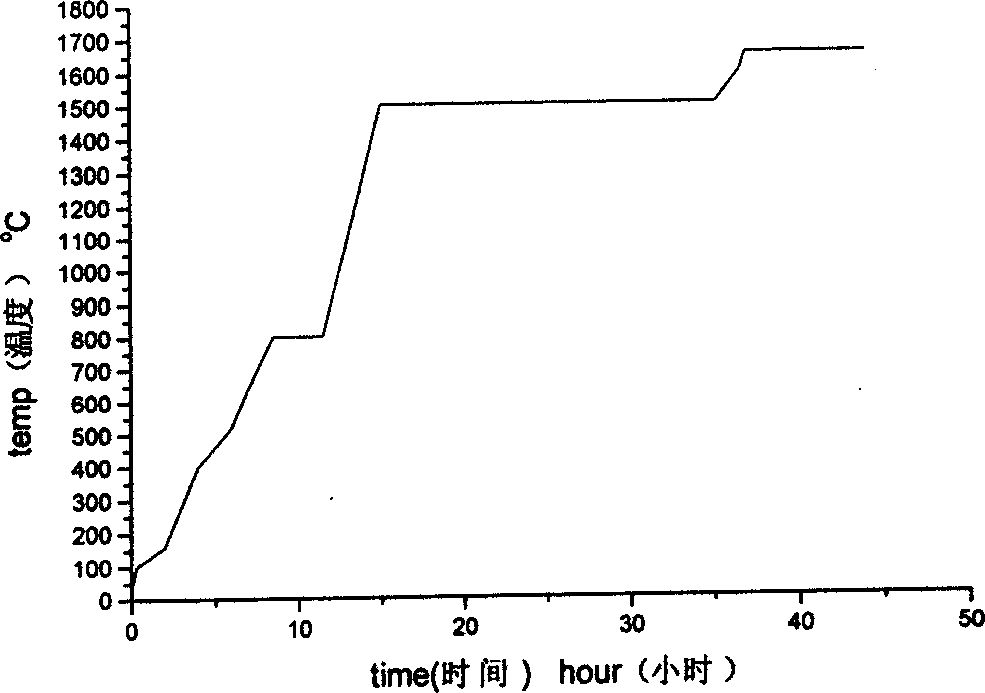

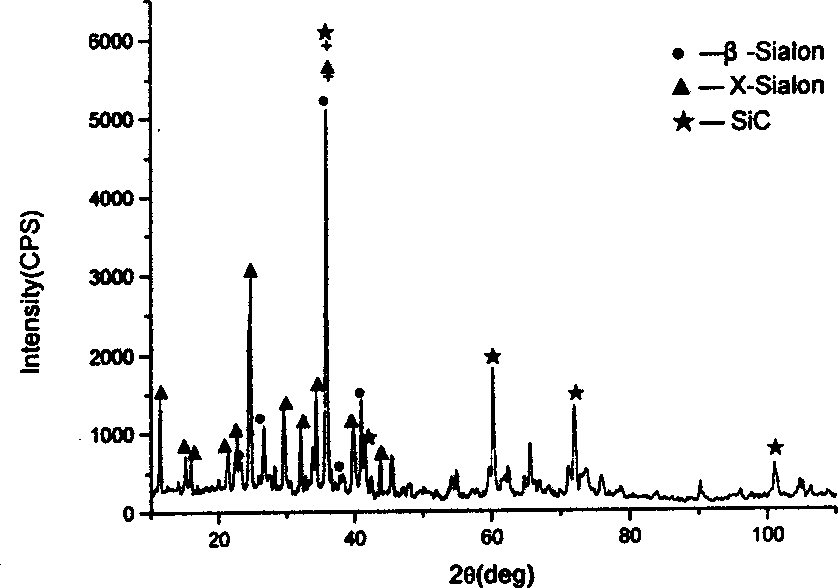

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be described in detail below. 1. Chemical composition and basic formula design of starting materials

[0018] Adopt solid waste slag-coal gangue prepared by the present invention, the chemical composition of fly ash is as follows:

[0019] The chemical composition of coal gangue is as follows: SiO 2 : 60.28; Al 2 o 3 : 28.37; Fe 2 o 3 : 4.94; CaO: 0.92; MgO: 1.26;

[0020]Industrial analysis of coal gangue: ash: 83.24; volatile matter: 9.20; fixed carbon: 7.56

[0021] Chemical composition of fly ash: SiO 2 : 51.52; Al 2 o 3 : 33.43; Fe 2 o 3 : 8.86; CaO: 4.9; specific surface area 3108cm 2 / g

[0022] The chemical composition of the clay (Zibo, Shandong) that is adopted is as follows:

[0023] SiO 2 : 67.04; Al 2 o 3 : 16.19; Fe 2 o 3 : 5.39; CaO: 1.45; MgO: 1.40; K 2 O+Na 2 O: 2.01; Burn Vector: 6.55

[0024] In order to further reduce the iron content in the solid waste residue, the finely ground raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com