Cementing material, all-solid waste concrete and preparation method of all-solid waste concrete

A technology of cementitious materials and waste concrete, which is applied in the direction of solid waste management, sustainable waste treatment, cement production, etc., can solve the problems of single type of solid waste, unsatisfactory demand, unusable steel slag raw materials, etc., to improve mechanical properties, Meet the needs of use and reduce the effect of environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

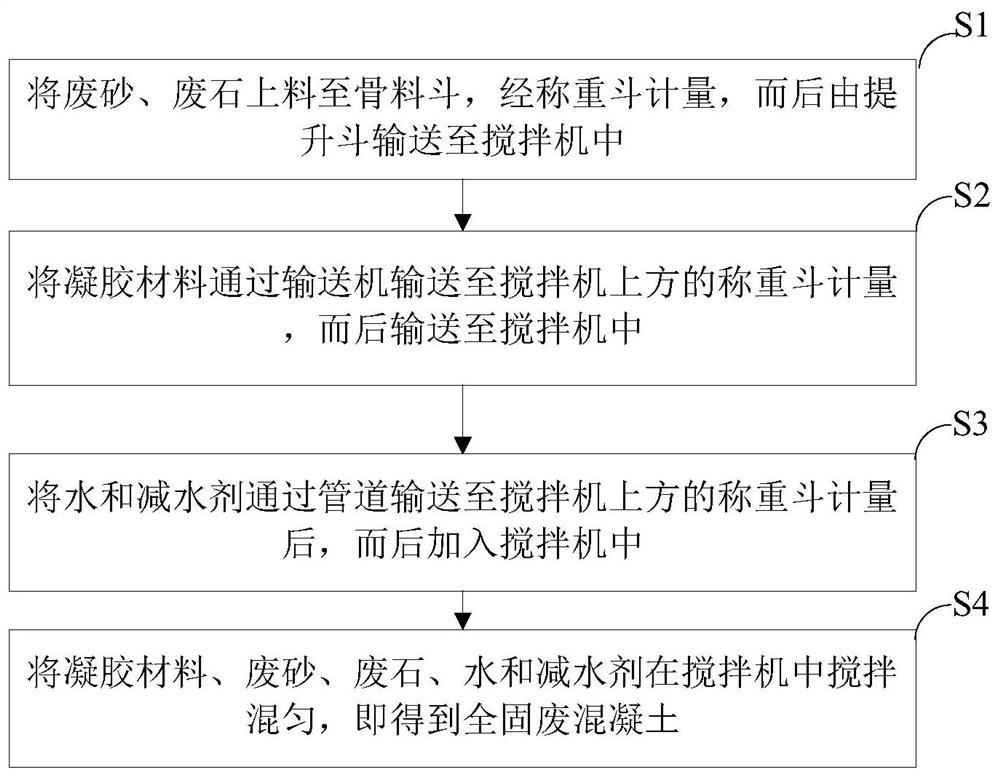

Method used

Image

Examples

Embodiment 1

[0032] Pretreatment of steel slag, slag, desulfurized gypsum, and calcium phosphate slag raw materials: steel slag powder is ground to a specific surface area of 500m 2 / kg; After the slag is crushed, it is transported to the ball mill for grinding until the specific surface area is 500m 2 / kg. The desulfurized gypsum is dried and pretreated, and sent to the ball mill for grinding until the specific surface area is 420m 2 / kg. Calcium phosphate slag is pre-dried and sent to the ball mill for grinding until the specific surface area is 570m 2 / kg.

[0033] The pretreated steel slag powder, slag powder, desulfurized gypsum powder and calcium phosphate slag powder were added to the ball mill according to the mass percentages shown in Table 1 below, and the cementitious material was obtained after grinding and mixing.

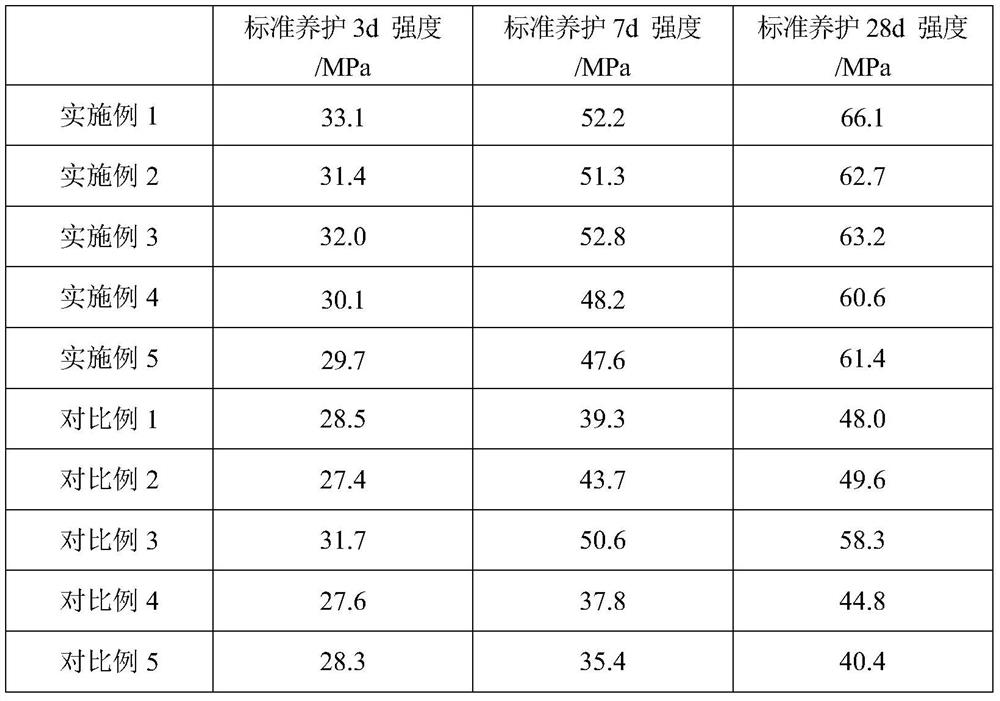

[0034] Table 1: The mass percentages of the various components of the gelled material prepared in Examples 1-5 and Comparative Examples 1-5

[0035] ...

Embodiment 2-5

[0037] On the basis of Example 1, gelling materials were prepared respectively according to the contents of the formula components shown in Table 1. Wherein, embodiment 2 replaces the calcium phosphate slag powder in the cementitious material composition of embodiment 1 with waste catalyst; embodiment 3 replaces the calcium phosphate slag powder in the cementitious material composition of embodiment 1 with the alkali after neutralizing the acid sewage sexual sludge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com