Synthesis of active ferrous sulphide and uses thereof

A ferrous sulfide and synthesis method technology, applied in the field of non-ferrous metallurgy, can solve the problems of poor selectivity, large alkali consumption, low purity of nickel hydroxide or nickel carbonate, etc., and achieve high production efficiency, less co-precipitation, and nickel precipitation high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

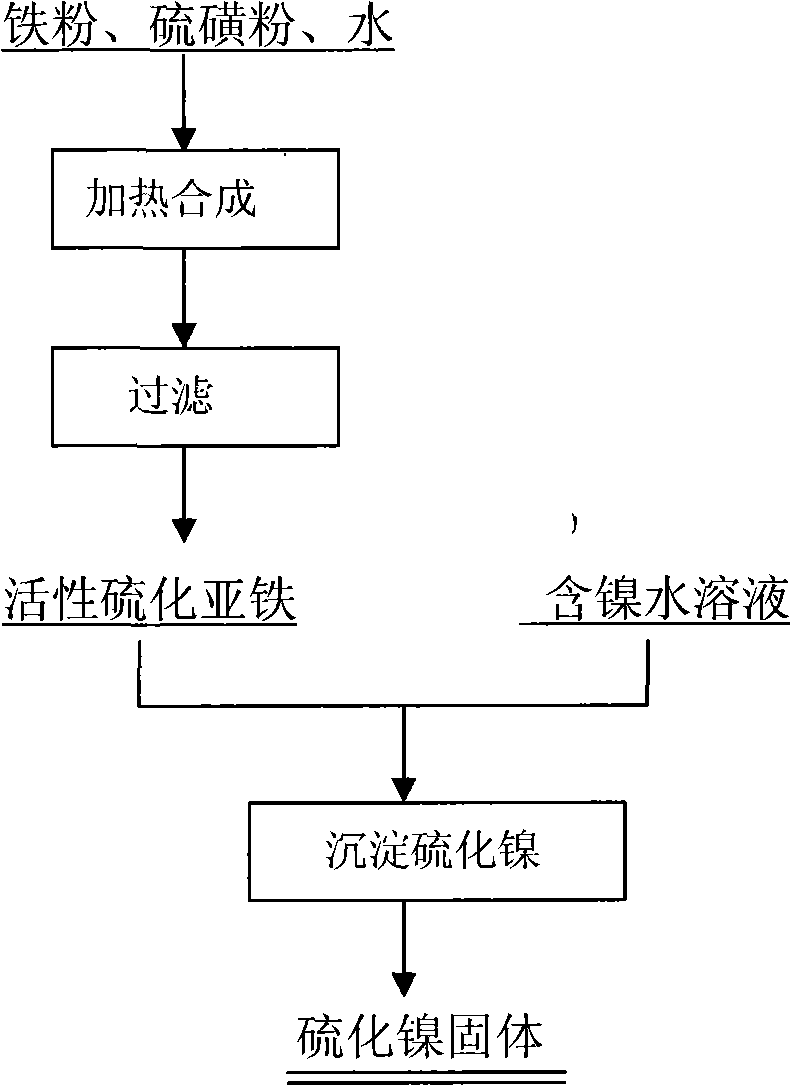

Method used

Image

Examples

Embodiment 1

[0012] Mix 78.2g of iron powder (metal iron content 93%) with 46.0g of sulfur powder (main content 99%), add 120g of water and mix evenly, add to a stirring reactor and heat to 80-90°C, stir for 2 hours, cool, and filter After obtaining active ferrous sulfide, its main content (FeS) is 89.45%, and the average particle diameter is 12.54 μm;

[0013] Add 5.0 liters of nickel-containing aqueous solution (main components Ni12.56g / l, Fe 42.34g / l, pH value 2.0) into the stirred reactor, add active ferrous sulfide, heat to 60-70°C, stir for 2 hours, cool , filtration, the quality of the obtained nickel sulfide solid after drying is 190.4g, containing 32.75% nickel, and the nickel precipitation rate is 98.52%.

Embodiment 2

[0015] Mix 78.2g of iron powder (metal iron content 93%) with 54.6g of sulfur powder (main content 99%), add 200g of water and mix evenly, add to a stirring reactor and heat to 100-110°C, stir and react for 1 hour, cool and filter After obtaining active ferrous sulfide, its main content (FeS) is 82.79%, and the average particle diameter is 16.63 μm;

[0016] Add 5.0 liters of nickel-containing aqueous solution (main components Ni12.56g / l, Fe 42.34g / l, pH 2.0) into the stirred reactor, add active ferrous sulfide, heat to 75-85°C, stir for 1 hour, cool , filtration, the quality of the obtained nickel sulfide solid after drying is 207.7g, containing 29.37% nickel, and the nickel precipitation rate is 97.12%.

Embodiment 3

[0018] Mix 78.2g of iron powder (metal iron content 93%) with 62.3g of sulfur powder (main content 99%), add 300g of water and mix evenly, add to a stirring reactor and heat to 120-130°C, stir and react for 0.5 hours, cool and filter After obtaining active ferrous sulfide, its main content (FeS) is 75.93%, and the average particle diameter is 19.42 μm;

[0019] Add 5.0 liters of nickel-containing aqueous solution (main components Ni12.56g / l, Fe 42.34g / l, pH value 2.0) into the stirred reactor, add active ferrous sulfide, heat to 90-100°C, stir for 0.5 hours, cool , filtration, the quality of the obtained nickel sulfide solid after drying is 227.9g, containing 26.21% nickel, and the nickel precipitation rate is 95.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com