Process of extracting high-purity pectin from apple pomace

An apple pomace, high-purity technology, applied in the field of pectin extraction, can solve the problems of environmental pollution, waste of resources, etc., to improve pectin extraction rate and pectin purity, improve pectin precipitation rate and pectin purity, and promote rapid The effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

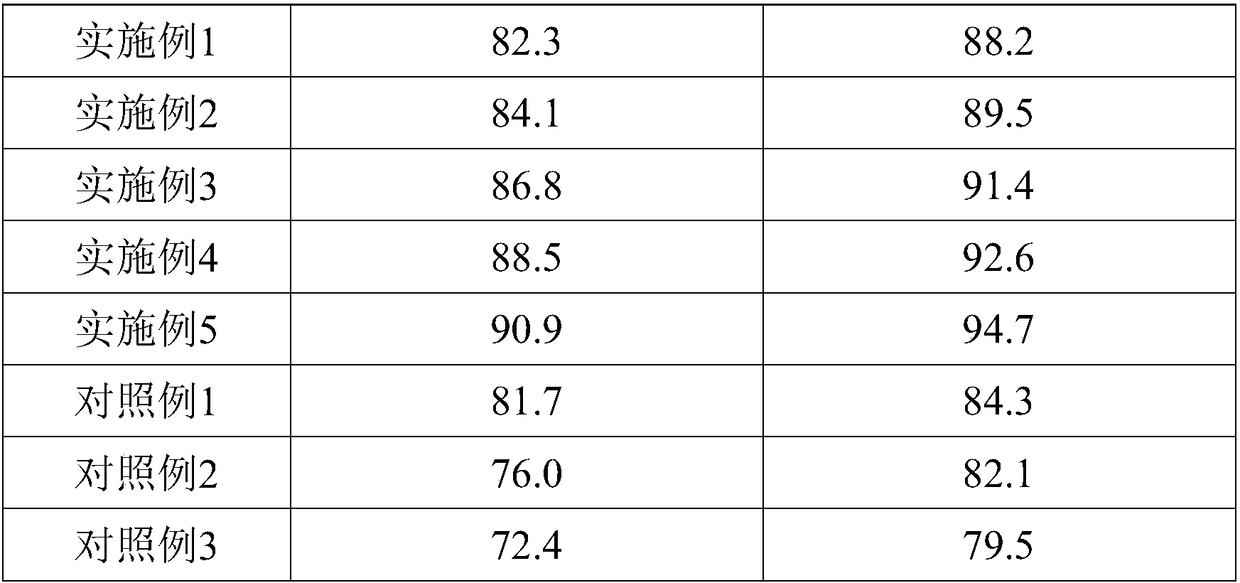

Examples

Embodiment 1

[0029] (1) Rinse and remove impurities: add warm water at 50-60°C to 25 kg of apple pomace, the ratio of material to liquid is 1:5, stir at 50-60°C for 15 minutes at a stirring speed of 30 r / min, centrifugally filter, and take the filter residue ;

[0030] (2) Flour making: the filter residue is dehydrated to constant weight through a freeze dryer, and is made into a 60-mesh powder by a pulverizer to obtain apple pomace powder;

[0031] (3) Acid extraction: Put the apple pomace powder into the extraction tank, then add hot water at 80-90°C, the ratio of solid to liquid is 1:5, adjust the pH value to 2 with dilute hydrochloric acid, and then stir at 120 r / min in the Keep stirring at 80-90°C for 3 hours, then raise the temperature to reflux state, keep stirring for 10 minutes, centrifugally filter, and take the filtrate;

[0032] (4) Decolorization: transfer the filtrate to the decolorization tank, and heat up to 70-80°C, then add a decolorizer (activated carbon) with 2% dry we...

Embodiment 2

[0038] (1) Rinse and remove impurities: add warm water at 50-60°C to 25 kg of apple pomace, the ratio of material to liquid is 1:5, stir at 50-60°C for 15 minutes at a stirring speed of 30 r / min, centrifugally filter, and take the filter residue ;

[0039] (2) Flour making: the filter residue is dehydrated to constant weight through a freeze dryer, and is made into a 60-mesh powder by a pulverizer to obtain apple pomace powder;

[0040] (3) Acid extraction: Put the apple pomace powder into the extraction tank, then add hot water at 80-90°C, the ratio of solid to liquid is 1:5, adjust the pH value to 2 with dilute hydrochloric acid, and then stir at 120 r / min in the Keep stirring at 80-90°C for 3 hours, then raise the temperature to reflux state, keep stirring for 10 minutes, centrifugally filter, and take the filtrate;

[0041] (4) Decolorization: transfer the filtrate to the decolorization tank, and heat up to 70-80°C, then add a decolorizer (activated carbon) with 2% dry we...

Embodiment 3

[0047] (1) Rinse and remove impurities: add warm water at 50-60°C to 25 kg of apple pomace, the ratio of material to liquid is 1:5, stir at 50-60°C for 15 minutes at a stirring speed of 30 r / min, centrifugally filter, and take the filter residue ;

[0048](2) Flour making: the filter residue is dehydrated to constant weight through a freeze dryer, and is made into a 60-mesh powder by a pulverizer to obtain apple pomace powder;

[0049] (3) Acid extraction: Put the apple pomace powder into the extraction tank, then add hot water at 80-90°C, the ratio of solid to liquid is 1:5, adjust the pH value to 2 with dilute hydrochloric acid, and then stir at 120 r / min in the Keep stirring at 80-90°C for 3 hours, then raise the temperature to reflux state, keep stirring for 10 minutes, centrifugally filter, and take the filtrate;

[0050] (4) Decolorization: transfer the filtrate into a decolorization tank, and heat up to 70-80°C, then add a decolorant with 2% dry weight of apple pomace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com