Mine settling pond

A sedimentation tank and mine technology, applied in the field of mine shaft engineering research, can solve the problems of cumbersome manual cleaning, unsatisfactory results, slow sedimentation in mine sedimentation tanks, etc., and achieve good sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

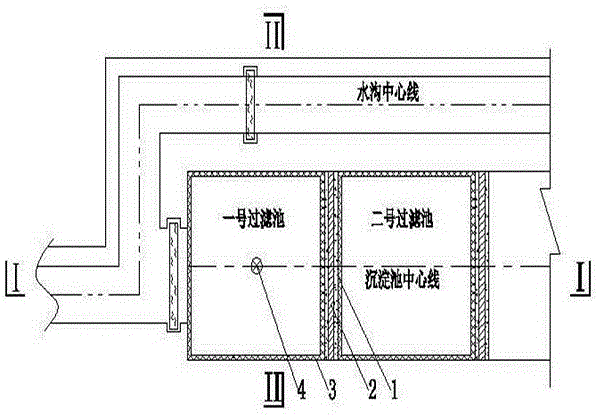

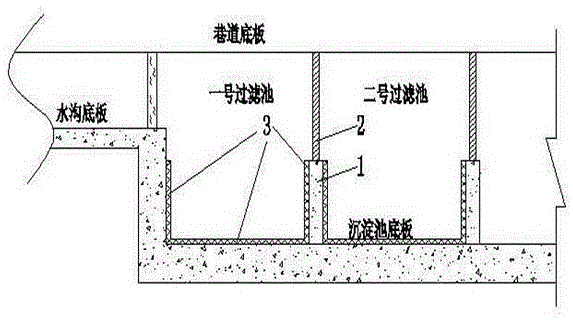

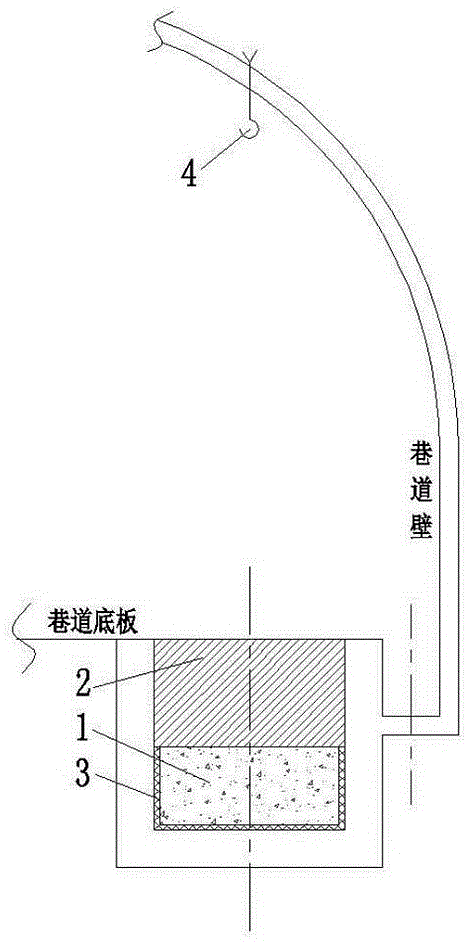

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The sedimentation tank that has been constructed is divided into several filter pools with a concrete retaining wall 1. The height of the retaining wall 1 is lower than the level of the bottom plate of the ditch. A stainless steel filter mesh 2 is installed on each retaining wall 1 to filter coal slime , and then use nylon monofilament mesh bag 3 to tile the bottom and surroundings of each filter tank, to ensure that the water in the ditch first flows into nylon monofilament mesh bag 3, and finally on the roadway wall directly above each nylon monofilament mesh bag 3 A suspension hook 4 is respectively set on the top. The water in the ditch enters the sedimentation tank and first settles in the No. 1 filter tank, and the sediment falls into the nylon monofilament mesh bag 3, and the water after the preliminary precipitation flows into the next filter tank after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com