Multi-stage sedimentation tank for wastewater of dust removal and desulfurization equipment

The technology of desulfurization equipment and secondary sedimentation tank is applied in the field of sedimentation tank, which can solve the problems of poor sedimentation effect, large floor space, boundary pollution, etc., and achieve the effects of improving sedimentation efficiency, convenient construction and installation, and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

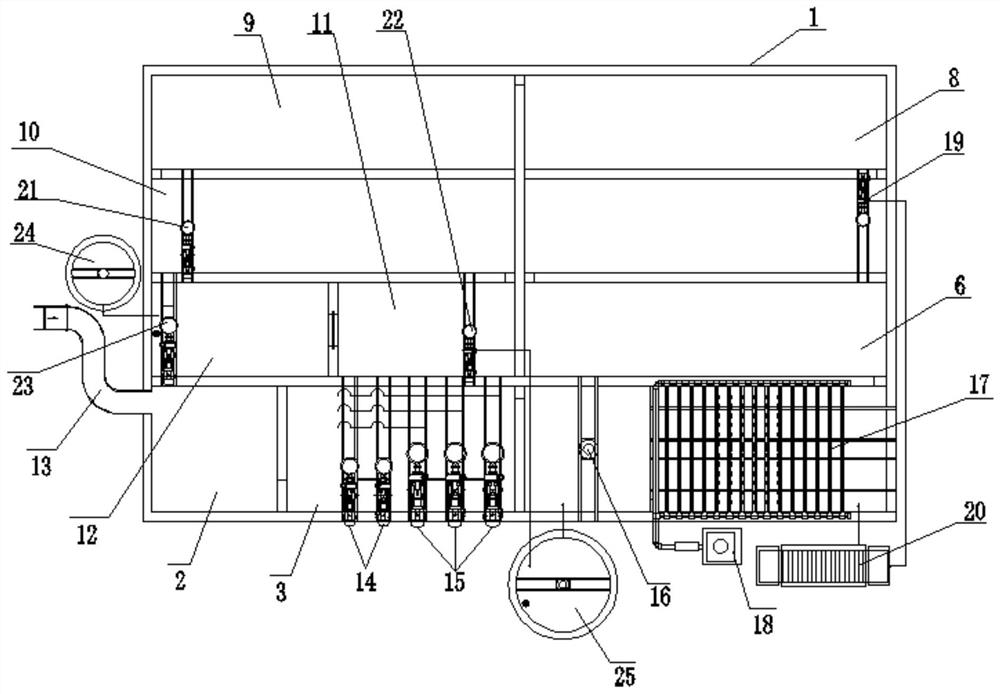

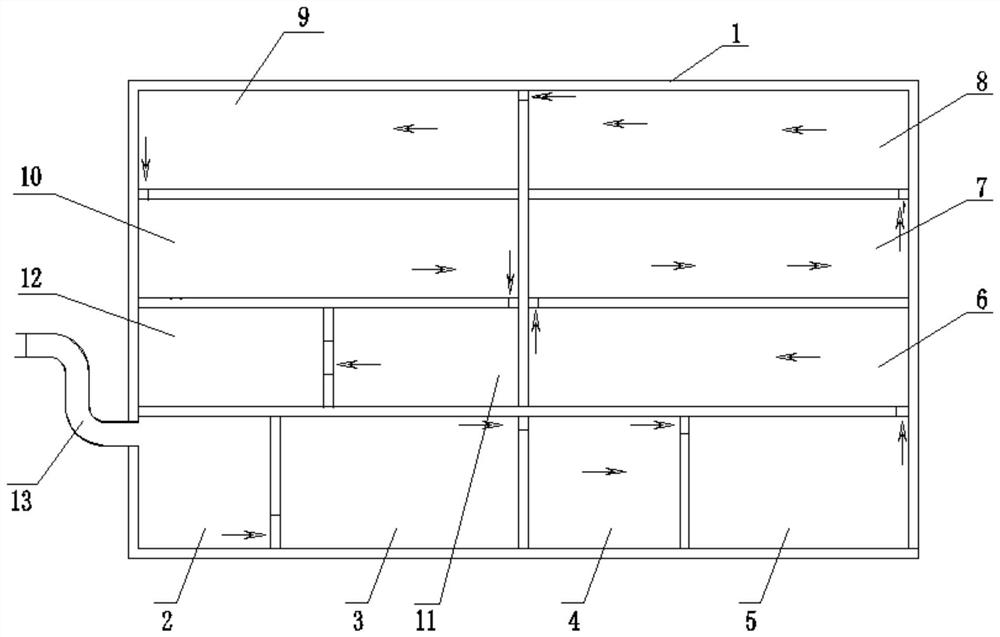

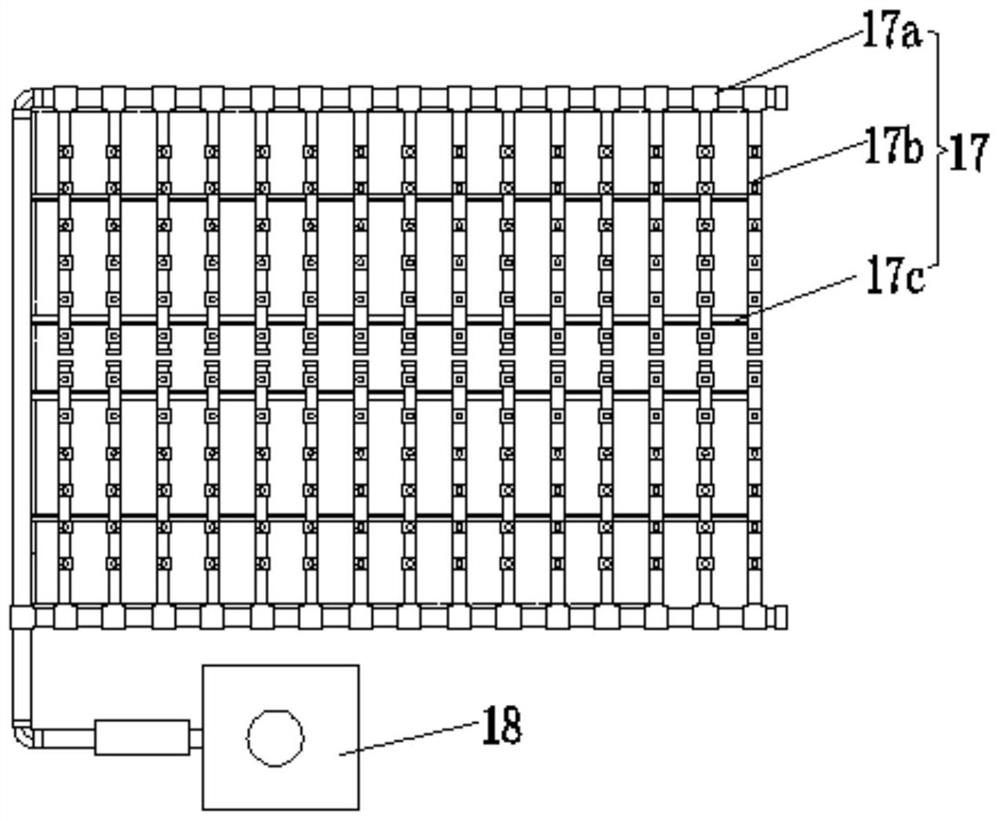

[0024] Such as Figure 1-3 As shown, a multi-stage sedimentation tank for dust removal and desulfurization equipment wastewater includes a sedimentation tank body 1. The sedimentation tank body 1 is a cuboid structure with an unsealed upper end, and a plurality of small pools are arranged inside, including a pH neutralization pool 2, Desulfurization circulation pool 3, reaction pool 4 and oxidation pool 5, pH neutralization pool 2, desulfurization circulation pool 3, reaction pool 4 and oxidation pool 5 are arranged in sequence from left to right, and are connected to each other, oxidation pool 5 and reaction pool 4 There is a first-level sedimentation tank 6 in front, and a second-level sedimentation tank 7 and a third-level sedimentation tank 8 are arranged in front of the first-level sedimentation tank 6, and the first-level sedimentation tank 6, the second-level sedimentation tank 7 and the third-level sedimentation tank 8 are connected to each other , the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com