Device for realizing gas-liquid-solid three-phase separation in sewage treatment and application method thereof

A three-phase separation, sewage treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. , the problem of shortening the sequencing batch time, etc., to achieve the ideal precipitation effect, increase the conveying volume, and improve the precipitation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

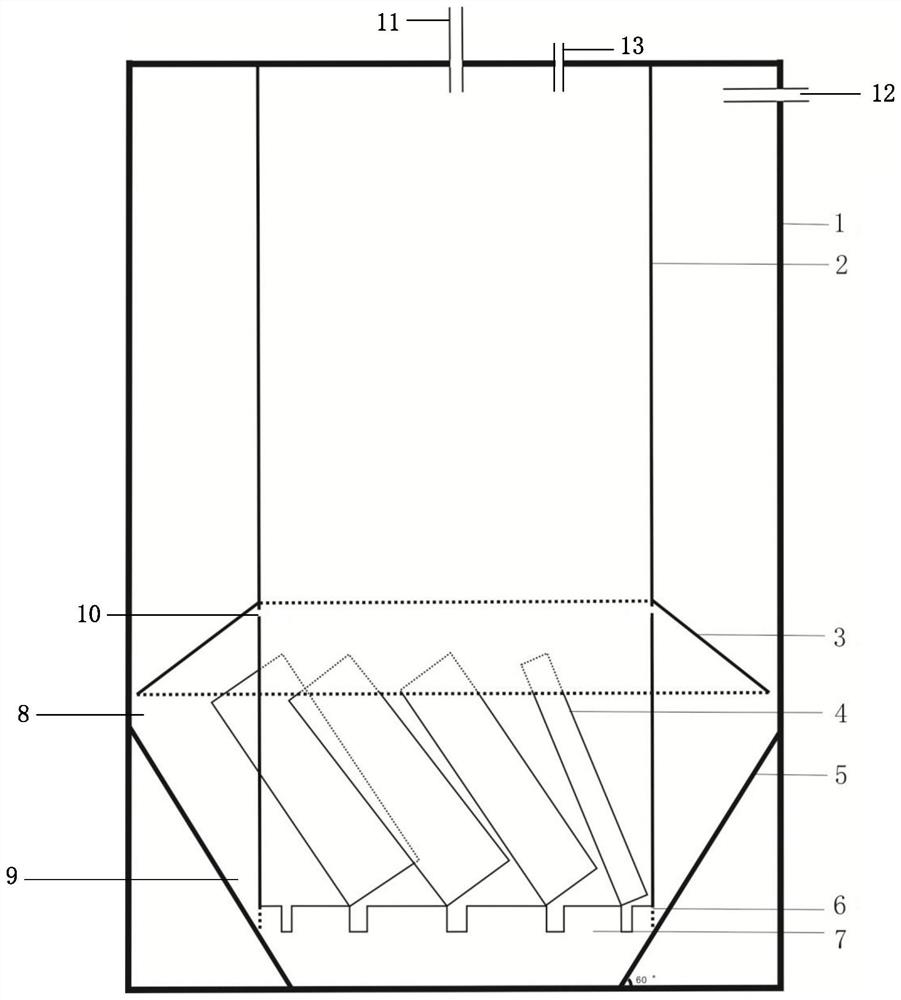

[0047]The invention discloses a device including but not limited to three-phase separation of gas, liquid, and solid (suspended matter) in sewage treatment equipment and an application method thereof. The device includes a barrel body, which includes a double-layer concentric outer barrel and an inner barrel. , Lower cone, upper cone and spiral sedimentation plate; suppose the outer barrel (circle is the diameter, square is the side length, the same below) diameter or side length is R, height is H, and the number of spiral sedimentation plates is N; Its structure and structure are as follows:

[0048]Outer barrel: a cylindrical (cube) barrel with a diameter (or side length) of R and a height of H, which is the load-bearing body and outer structure of the three-phase separator.

[0049]Lower cone: a cone with a lower radius of 0.5R and an upper radius of R, placed at the bottom of the outer barrel and connected with the bottom and the inner wall of the outer barrel.

[0050]Inner barrel: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com