Rotary wheel and rotary vane compressor

A compressor and runner technology, applied in the field of volumetric rotary rotor compressors, can solve the problems of increased leakage value, easy jamming, affecting the working efficiency and service life of the compressor, and achieves a small displacement angle and stable overall movement. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

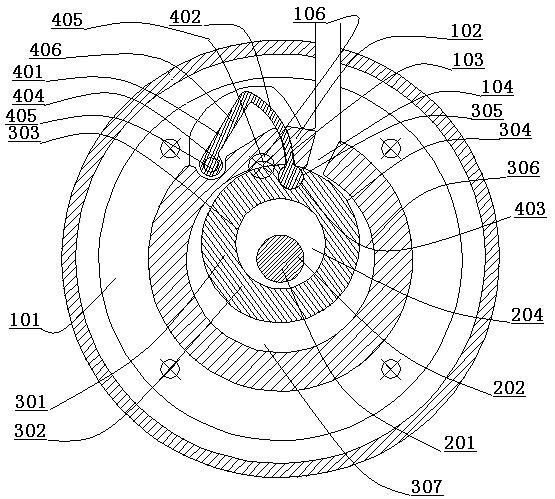

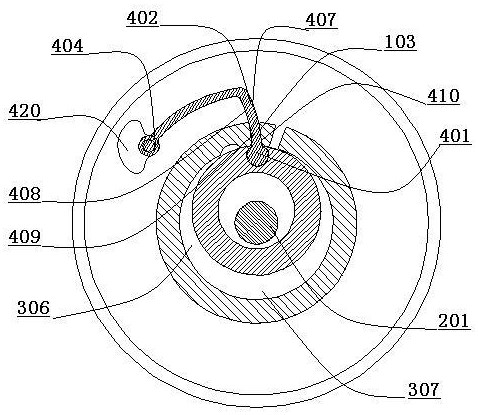

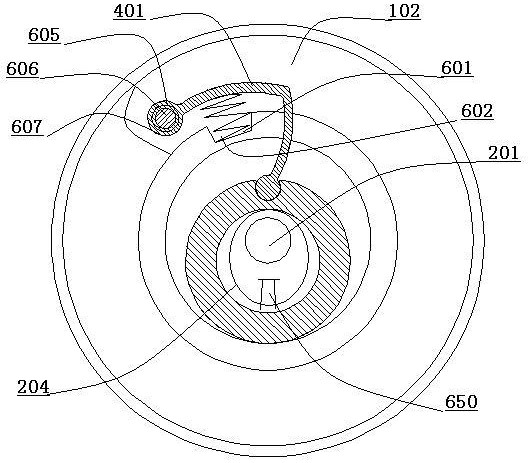

[0041] Such as figure 1 As shown, the rotary vane compressor includes a stator 101 , a crankshaft 201 , a rotary wheel 301 and a rotary vane 401 . On the wall surface of the cylinder liner 102 of the stator 101, a rotary vane groove 103 is arranged radially, and the two sides of the rotary vane groove 103 are provided with an air inlet 104 and an exhaust port 105, and an exhaust valve 106 is arranged on the exhaust port 105 . The shaft body 202 of the crankshaft 201 is arranged concentrically with the cylinder liner 102 , and the journal 204 of the crankshaft 201 is arranged inside the stator 101 . The wheel sleeve 303 at the center of the wheel body 302 of the runner 301 is arranged on the outside of the journal 204, and the outer circular wall surface 304 of the wheel body 302 is provided with a circular slide groove 305; the runner 301 separates the cylinder chamber 306 inside the stator 101 into a crescent Shaped volume cavity 307 . The top of the arc-shaped blade 402 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com