Method for recycling tungsten and ammonia in one step from ammonium paratungstate crystallization mother solution smelt through tungsten

A technology of ammonium paratungstate and crystallization mother liquor, applied in the field of tungsten hydrometallurgy, can solve the problems of high cost, incomplete tungsten precipitation, long process, etc., and achieve the effects of solving environmental protection problems, high precipitation recovery rate and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

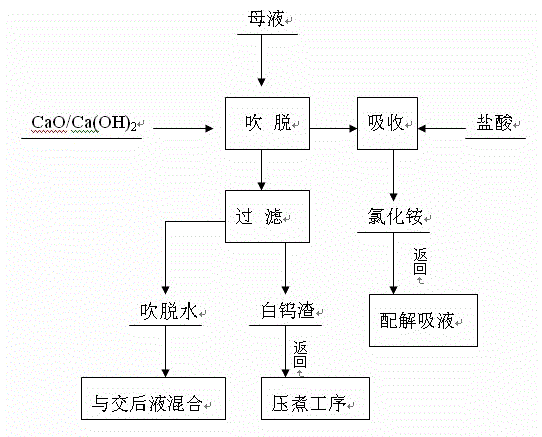

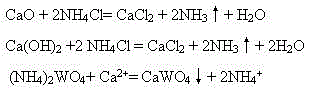

[0021] After the evaporation and crystallization of APT is completed, the ammonium paratungstate solution pumped from the mother liquor to the blow-off reactor contains 20 g / L tungsten trioxide, 20 g / L ammonium ion, and the volume of the solution is 500 mL. 17.2 grams, the excess coefficient of its theoretical molar stoichiometric ratio is 1.11, blow off ammonia and sink tungsten in the stripping reactor, the ammonia gas that blows off is separated by condensing gas-liquid, and is made into ammonium chloride with hydrochloric acid spraying, The ammonium chloride is returned to the configuration analysis solution, and the scheelite slag is returned to the pressure cooking process; the content of tungsten trioxide in the solution after analysis and stripping is 1 mg / L, and the ammonium ion is 30 mg / L; the content of tungsten trioxide in the filter residue is 63.32%.

Embodiment 2

[0023] After the evaporation and crystallization of APT is completed, the ammonium paratungstate solution pumped from the mother liquor to the blow-off reactor contains 21.5 g / L tungsten trioxide, 22.5 g / L ammonium ion, the volume of the solution is 2000 mL, and 84 g of calcium oxide with a main component of more than 90% is added , the excess coefficient of its theoretical molar stoichiometric ratio is 1.2, and the stripping of ammonia and precipitation of tungsten is carried out in the stripping reactor. The ammonia gas blown out is separated by condensing gas and liquid, sprayed with hydrochloric acid to make ammonium chloride, ammonium chloride is returned to configure the analysis solution, and the scheelite slag is returned to the pressure cooking process; the content of tungsten trioxide in the solution after analysis is 5 mg / L, ammonium ion 25.8 mg / L; the filter residue contains 65.72% tungsten trioxide.

Embodiment 3

[0025] After the evaporation and crystallization of APT is completed, the ammonium paratungstate solution pumped from the mother liquor to the blow-off reactor contains 18g / L tungsten trioxide, 21 g / L ammonium ion, and the volume of the solution is 2000mL. By adding 85g of calcium oxide with a main component of more than 90% , the excess coefficient of its theoretical molar stoichiometric ratio is 1.3, and the stripping of ammonia and precipitation of tungsten is carried out in the stripping reactor. The blown out ammonia gas is separated by condensing gas and liquid, sprayed with hydrochloric acid to make ammonium chloride, ammonium chloride is returned to configure the analysis solution, and scheelite slag is returned to the pressure cooking process. The content of tungsten trioxide in the stripped liquid was analyzed to be 1 mg / L, and the ammonium ion was 29 mg / L. The filter residue contains 64.53% tungsten trioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com