Method for extracting rhenium from copper smelting flue gas wet dust collecting liquid

A technology of wet dust collection and copper smelting, applied in the direction of improving process efficiency, etc., can solve the problems of high secondary disposal costs, high operating costs, and large investment, and achieve the effects of easy implementation, low production costs, and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

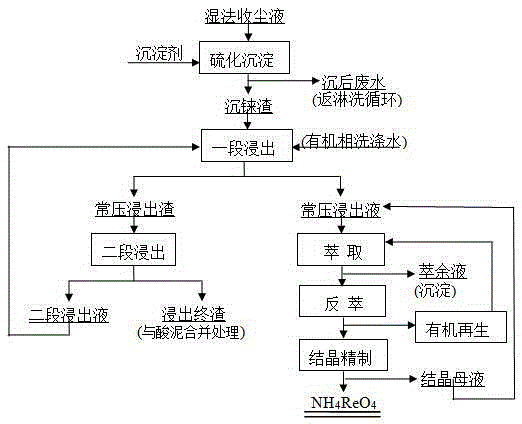

Method used

Image

Examples

Embodiment 1

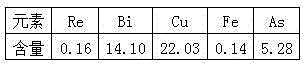

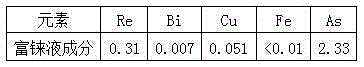

[0020] The composition of the wet dust collection liquid produced by a certain process of a copper production enterprise is shown in Table 1. The wet dust collection liquid from copper smelting flue gas is placed in a stirring tank, and a 20% sodium thiosulfate solution is added. To precipitate rhenate ions, the amount of sodium thiosulfate solution added is 100 times the theoretical amount of rhenium in the dust collection liquid. The precipitation reaction time is 3.0 hours, and the reaction temperature is 40°C. After the precipitation reaction, filter to obtain precipitated rhenium slag and precipitated rhenium After liquid, the liquid after sinking rhenium is returned to the waste acid water treatment system, and the rhenium sinking slag is selectively leached rhenium in two stages at normal pressure. The composition of the sinking rhenium slag produced is shown in Table 2.

[0021] Table 1 Composition of wet dust collection fluid / g / L

[0022]

[0023] Table 2 Typical c...

Embodiment 2

[0032] The composition of the wet dust collection liquid produced by a certain process of a copper production enterprise is shown in Table 5. The wet dust collection liquid from copper smelting flue gas is placed in a stirring tank, and a sodium thiosulfate solution with a mass concentration of 32% is added. To precipitate rhenate ions, the amount of sodium thiosulfate solution added is 150 times the theoretical amount of rhenium in the dust collection liquid. The precipitation reaction time is 4.0 h, and the reaction temperature is 30°C. The composition of the precipitated rhenium slag is shown in Table 6.

[0033] Table 5 Composition of wet dust collection fluid / g / L

[0034]

[0035] Table 6 Typical composition (%) of precipitated rhenium slag

[0036]

[0037] Weigh 500g of the sinking rhenium slag in Table 6, first adopt one stage of normal pressure leaching, the liquid before leaching is the second stage of normal pressure leaching liquid, the leaching process is pa...

Embodiment 3

[0044] The composition of the wet dust collection liquid produced by a certain process of a copper production enterprise is shown in Table 9. The wet dust collection liquid from copper smelting flue gas is placed in a stirring tank, and a 40% sodium thiosulfate solution is added. To precipitate rhenate ions, the amount of sodium thiosulfate solution added is 255 times the theoretical amount of rhenium in the dust collection solution. The precipitation reaction time is 4.0 h, and the reaction temperature is 50°C. The composition of the precipitated rhenium slag is shown in Table 10.

[0045] Table 9 Composition of wet dust collection fluid / g / L

[0046]

[0047] Table 10 Typical composition of rhenium slag (%)

[0048]

[0049]Weigh 500g of the sinking rhenium slag in Table 10, first adopt one stage of normal pressure leaching, the liquid before leaching is the second stage of normal pressure leaching liquid, the leaching process is passed through compressed air, the venti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com