Patents

Literature

70results about How to "Solve benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of lactobacillus plantarum for feed

InactiveCN103181460AReduce energy consumptionReduce fermentation costsAnimal feeding stuffAccessory food factorsAntibiotic YFeed additive

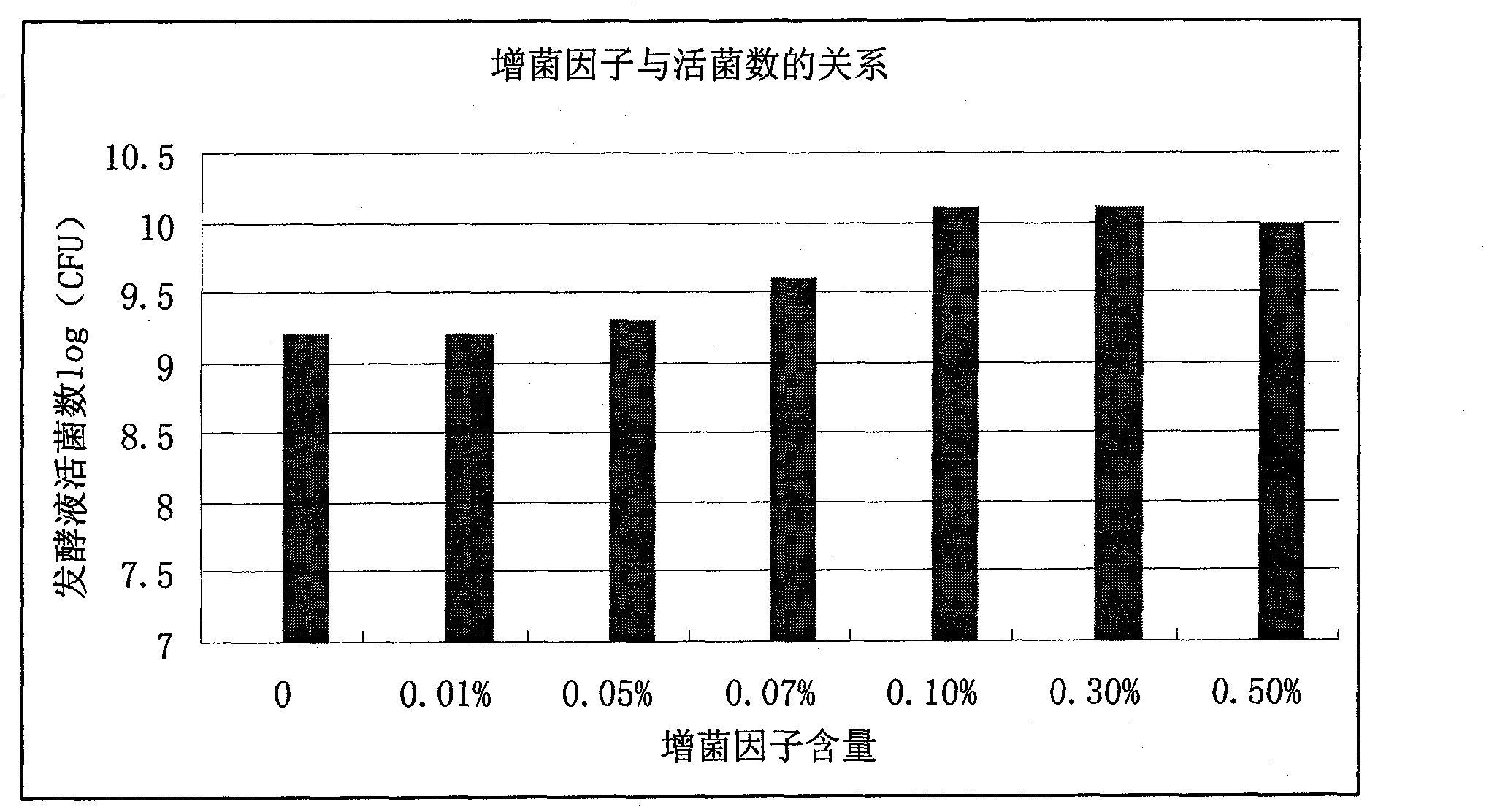

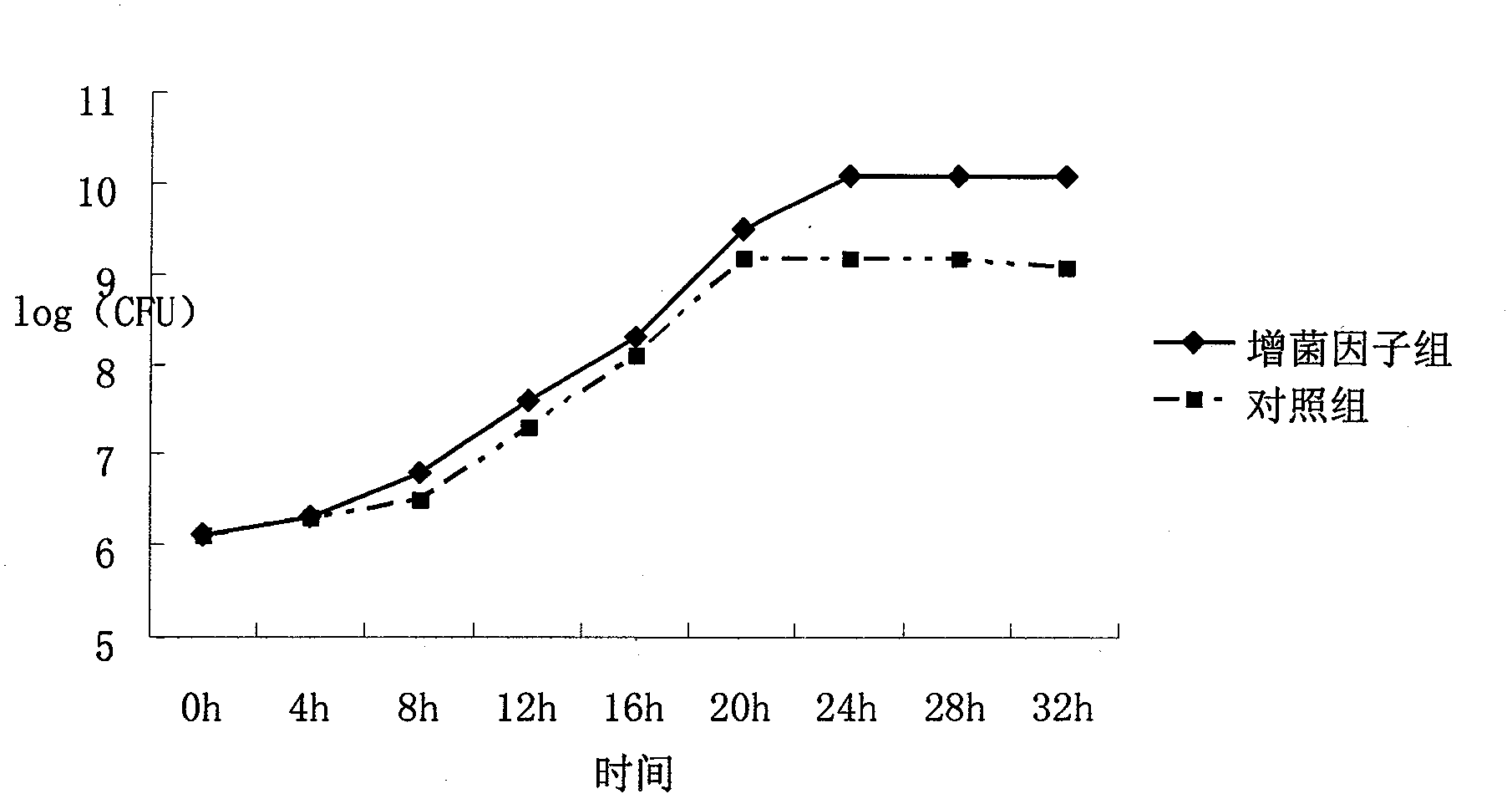

The invention provides a preparation method for lactobacillus plantarum used for a feed. To overcome the problems of abuse of antibiotics in farming, generation of drug resistance and the like at present, application of a novel antibiotic substitute product, i.e., probiotics, is a trend of modern farming. The probiotics is prepared through deep liquid state fermentation, has the advantages of low production cost and a high viable count and is a stable, highly-efficient and green feed additive.

Owner:北京资源亚太饲料科技有限公司

Method for removing sodium in industrial alumina at high temperature

InactiveCN103523812ASimple desodium processEffective solution to sodium removalAluminates/aluminium-oxide/aluminium-hydroxide purificationEngineeringMaterials science

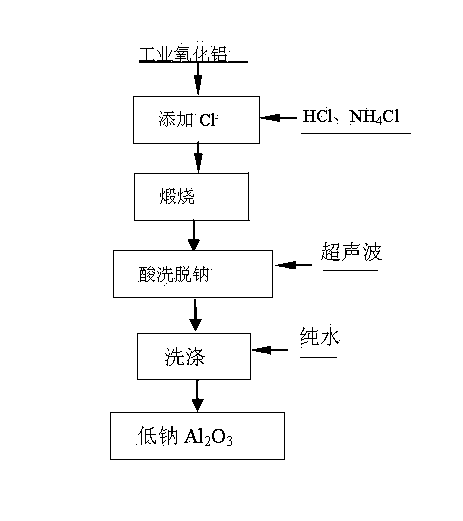

A method for removing sodium in industrial alumina at the high temperature comprises steps as follows: raw materials of industrial alumina, hydrochloric acid and ammonium chloride are placed in a container in the mass ratio of 100: (3-10): (3-8), simultaneously, a corresponding amount of water is added, and the mixture is fully mixed to obtain industrial alumina containing Cl<->; the industrial alumina containing Cl<-> is calcined; the calcined industrial alumina is cooled to the room temperature and subjected to acid pickling under the condition of an ultrasonic wave field; and the alumina subjected to acid pickling-ultrasonic wave treatment is washed for 1-2 hours by pure water at the washing temperature ranging from 60 DEG C to 90 DEG C until the pH is 7.0, the alumina is dried, and the alumina containing 0.0002%-0.0005% of sodium is obtained. By means of the method, the technical obstacles that sodium in industrial alumina in the production industry of industrial alumina cannot be effectively removed, the application range is small and the like are overcome, and a simple, effective and new way is provided for guaranteeing the product purity and realizing low-cost stabilizing production in the production industry of industrial alumina.

Owner:KUNMING METALLURGY INST

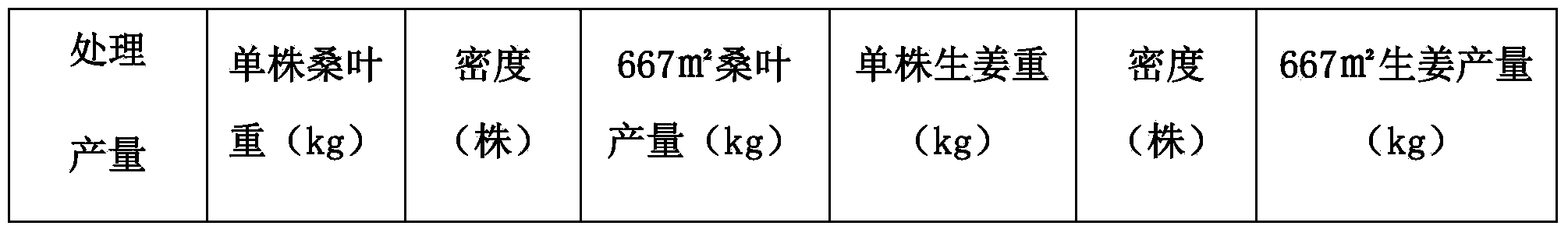

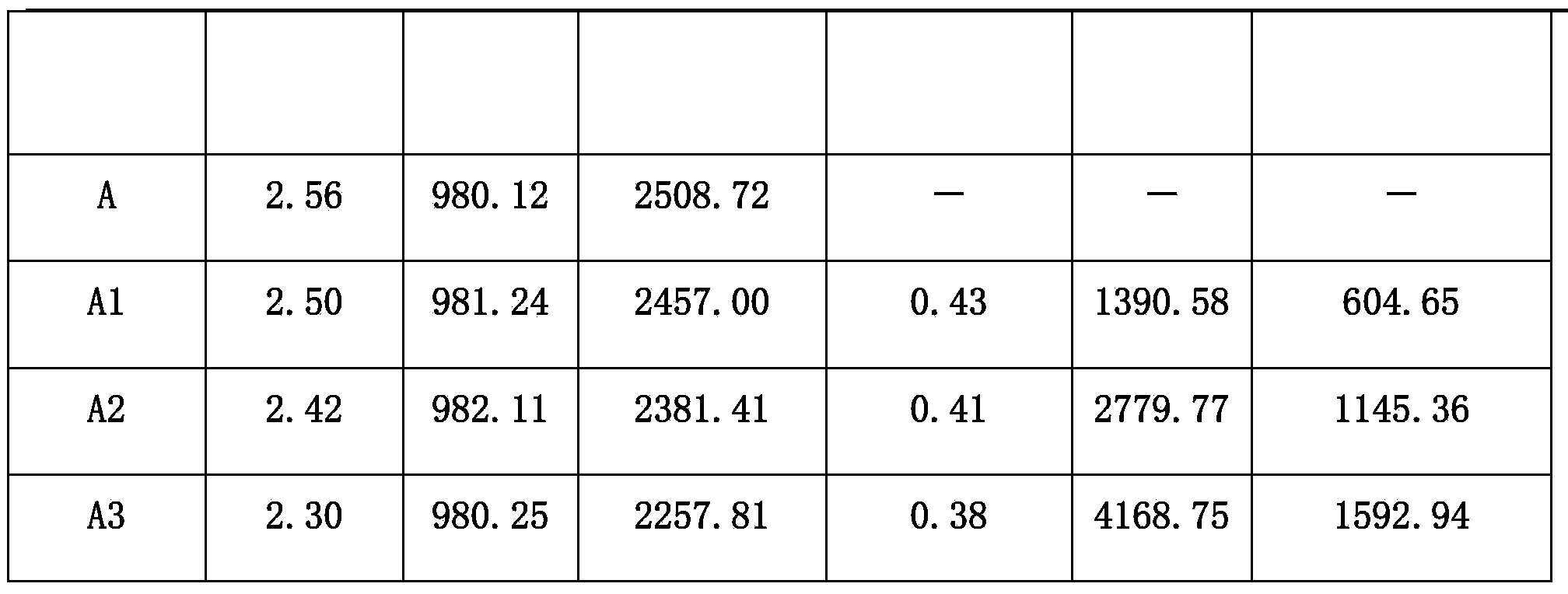

Cultivation method for interplanting ginger in mulberry field

A cultivation method for interplanting ginger in a mulberry field comprises applying potash fertilizer before winter, selecting ginger pieces for seed soaking and accelerating germination, performing drilling between Qingming and Grain Rain; applying spring fertilizer in mulberry field, applying autumn fertilizer before and after the beginning of autumn, the harvest of the ginger can be delayed, and the yield can be improved. According to the cultivation method for interplanting ginger in the mulberry field, growth characteristics of the mulberries and ginger are utilized to change the relationship of mutual competition of existing resources into a relationship of mutual utilization, the advantages are given into full play and the disadvantages are avoided, two key problems of insufficient resource utilization and reduction of comparative benefits during the planting process of the mulberries and the gingers can be solved, the yield per unit area of the mulberry field is increased, meanwhile, the production costs of mulberry and ginger planting can also be reduced, and the income of farmers is increased.

Owner:刘万顺

Early-bearing and high-yield Camellia oleifera cultivation method

ActiveCN105494002AIncrease productionHigh transmittanceCultivating equipmentsDiseaseCamellia oleifera

The invention relates to an early-bearing and high-yield Camellia oleifera cultivation method and belongs to the technical field of economic forest planting. The method comprises steps as follows: (1) establishment of forest land: selection of nursery stocks, land preparation, application of base fertilizer and planting; (2) management of a young forest: application of fertilizer, tending and weeding as well as tree shape pruning; (3) disease and pest control: disease control and pest control; (4) transplantation. With the adoption of the Camellia oleifera cultivation method, 60 kg of camellia oil is averagely produced per mu in the fifth year after planting, compared with the traditional yield of 10-15 kg of the camellia oil per mu, the yield is increased by 3-5 times, and the method is an important early high-yield and high-efficiency technology for Camellia oleifera. A Camellia oleifera high-yield forest has an area of 23 mu, 61.25 kg of the camellia oil is averagely produced per mu in 2015, and 1408.75 kg of the camellia oil is produced totally.

Owner:资源县贵盟金油茶开发有限责任公司

Method for high-yield cultivation of feed sweet sorghum in dry farming mountain land

InactiveCN104620823AAchieve high and stable productionAchieve efficiencySeed and root treatmentFertilising methodsSweet sorghumSeed treatment

The invention relates to a method for high-yield cultivation of feed sweet sorghum in dry farming mountain land. Dry farming planting technologies such as a dry farming full-membrane double ridge and furrow planting technology, a novel sustained or controlled release fertilizer scientific application technology, fine variety selection and seed treatment, repeated cutting harvesting and a membrane for two years are integrated; the problems of soil depletion, drought and water depletion of the dry farming mountain land, forage grass resource shortage, single variety, low and unstable planting yield of traditional sorghum and poor benefits are solved, and the high and stable yield of feed grass and cultural benefit increase are achieved. The yield of feed sweet sorghum fresh grass per mu (one mu is equal to 0.165 acre) is 7000-9000 kg, and the average yield is increased by over 60% compared with traditional open field planting.

Owner:LONGXI YONGSHUN FARMING DEV CO LTD

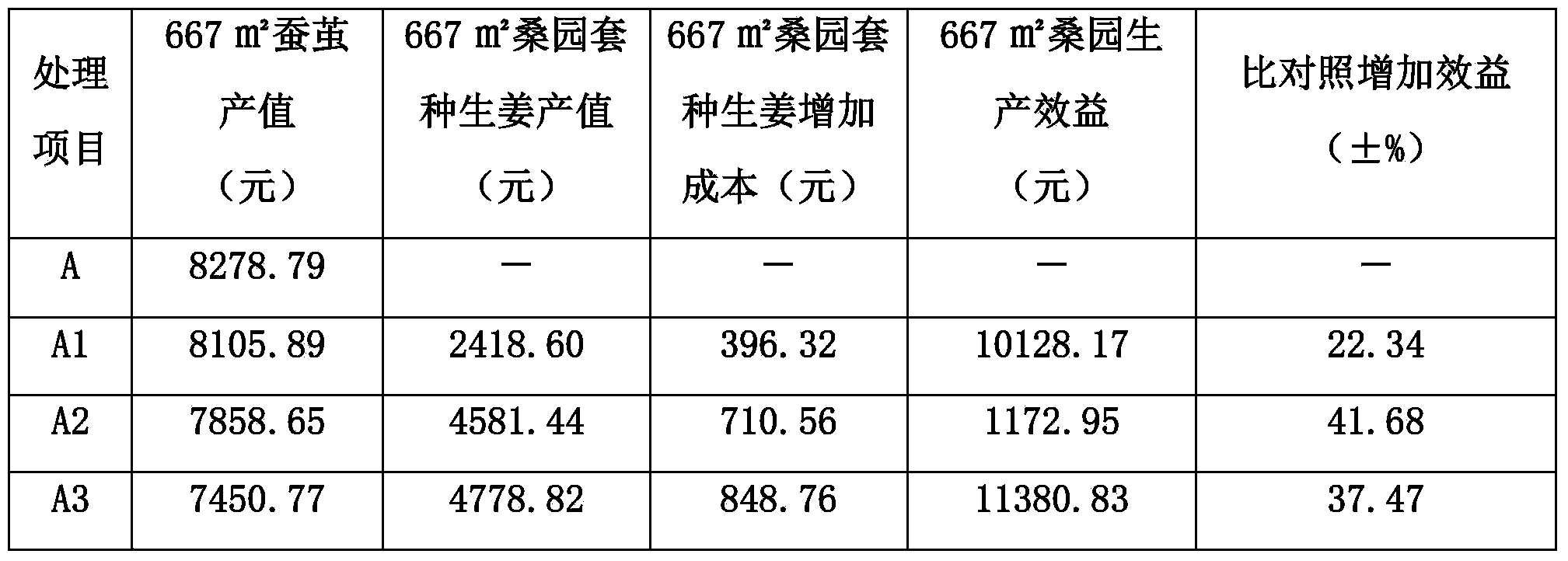

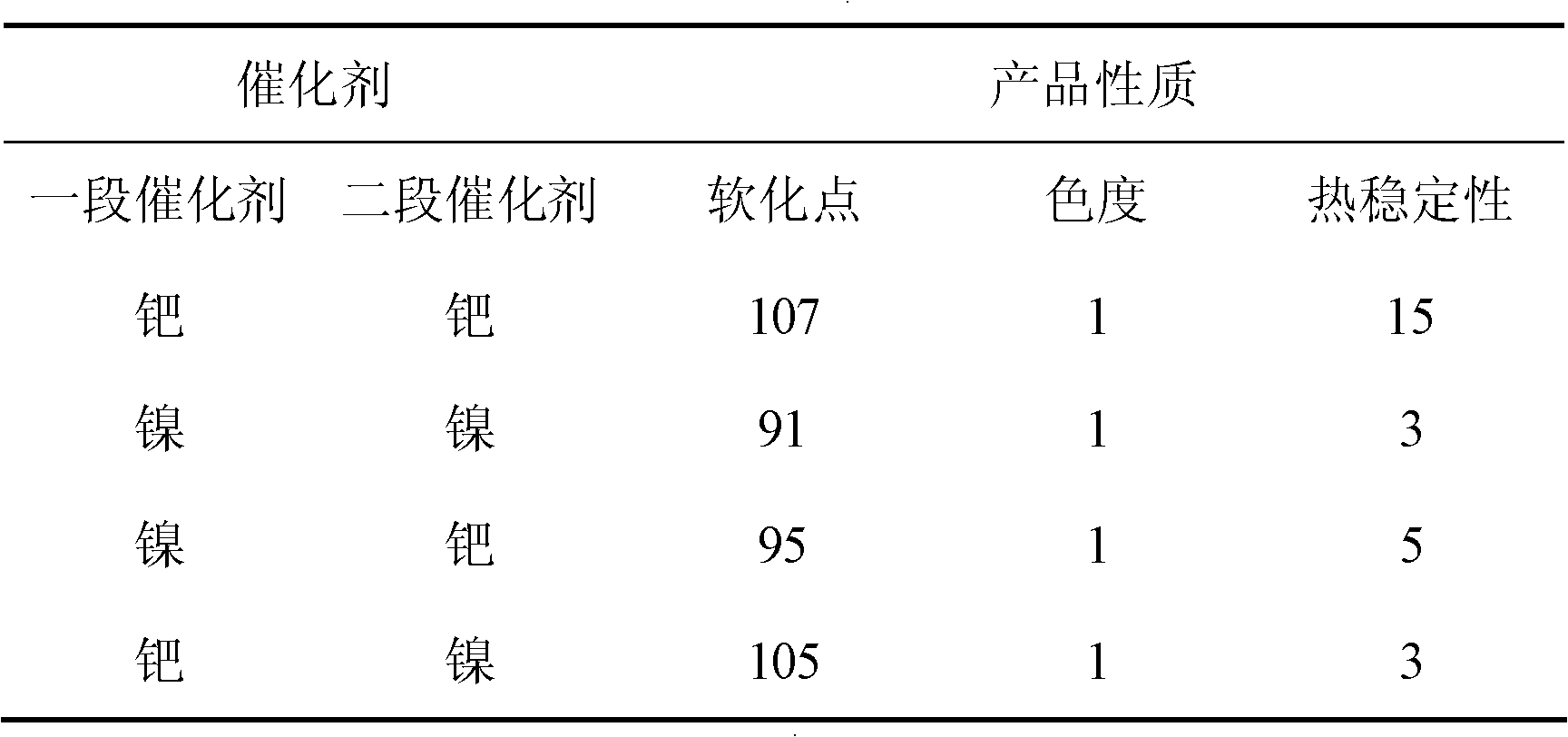

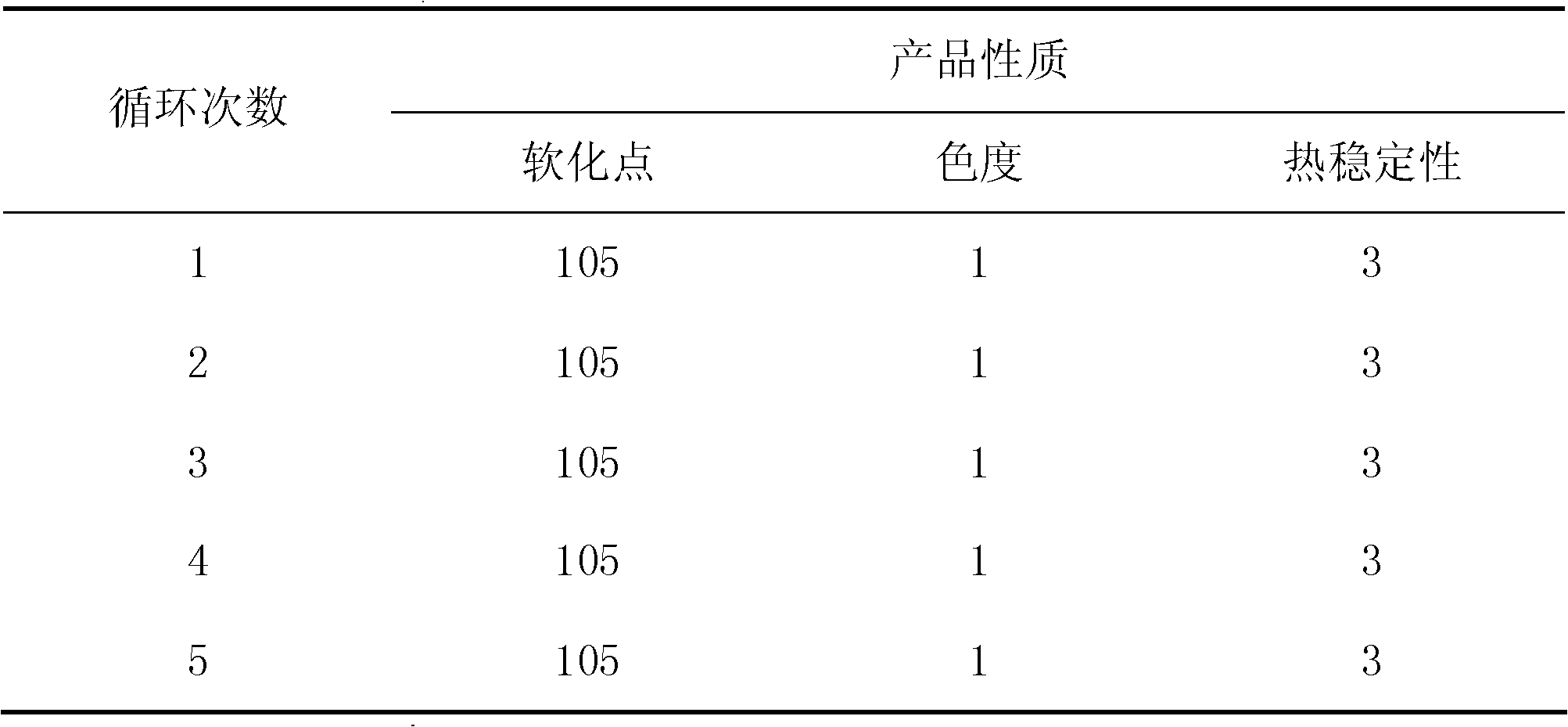

Method for preparing high-grade resin by catalytic hydrogenation

The invention discloses a method for preparing high-grade resin by catalytic hydrogenation and belongs to the technical field of resin catalytic hydrogenation. The method is characterized by comprising the following steps of: taking load type noble metal palladium as a first-section hydrogenation catalyst and taking framework nickel as a second-section hydrogenation catalyst; utilizing a two-section kettle type or a fixed bed continuous hydrogenation way to carry out hydrogenation reaction on the resin; and improving a resin color phase of the prepared hydrogenated resin to be water-white and have good heat stability. The method disclosed by the invention has the advantages of simple process and high catalyst activity, improves the resin chromaticity, improves the heat stability, slightly reduces the softening temperature, and has good economic benefits and wide industrial application prospect.

Owner:河北启明化工科技有限公司

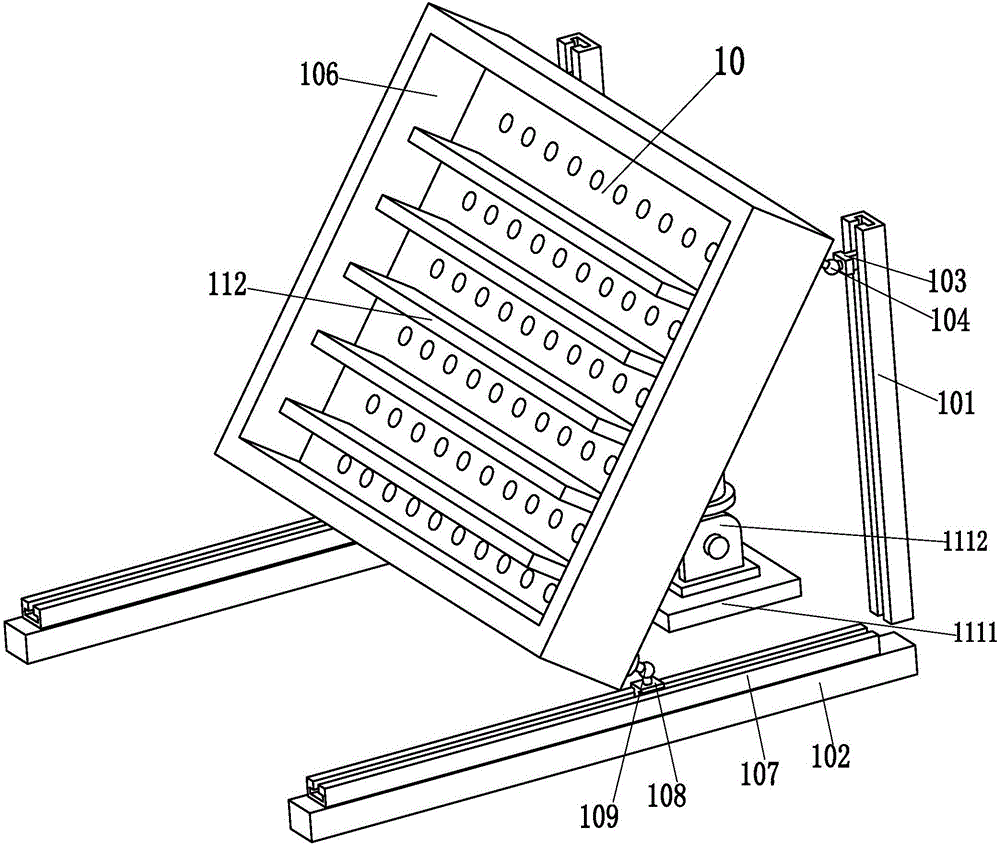

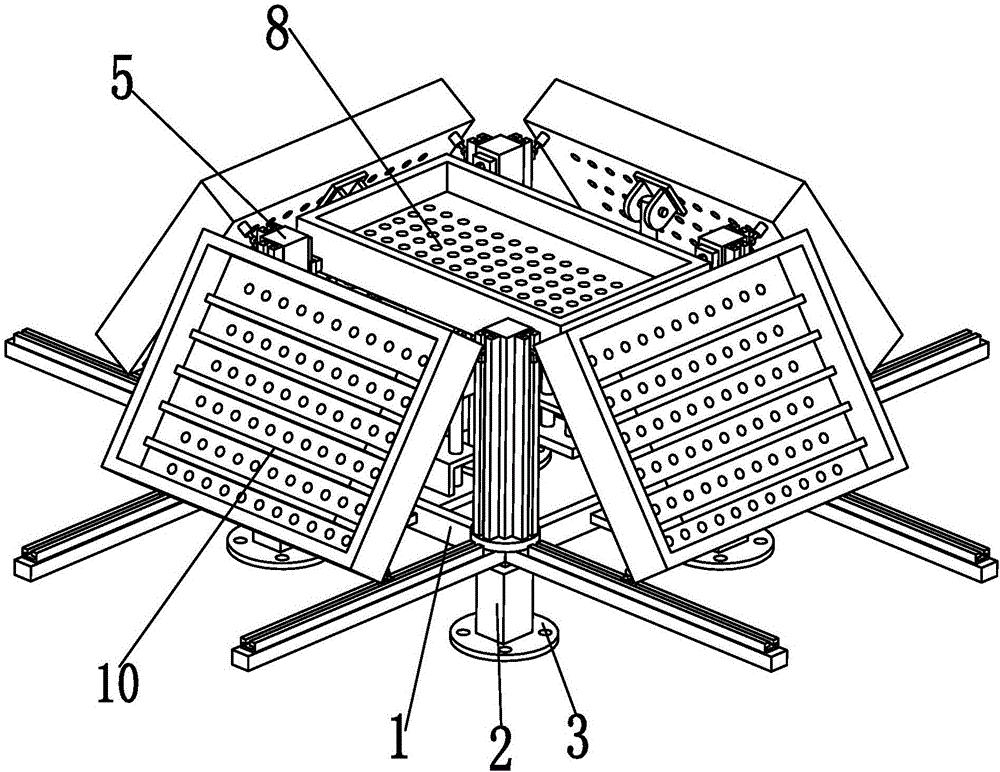

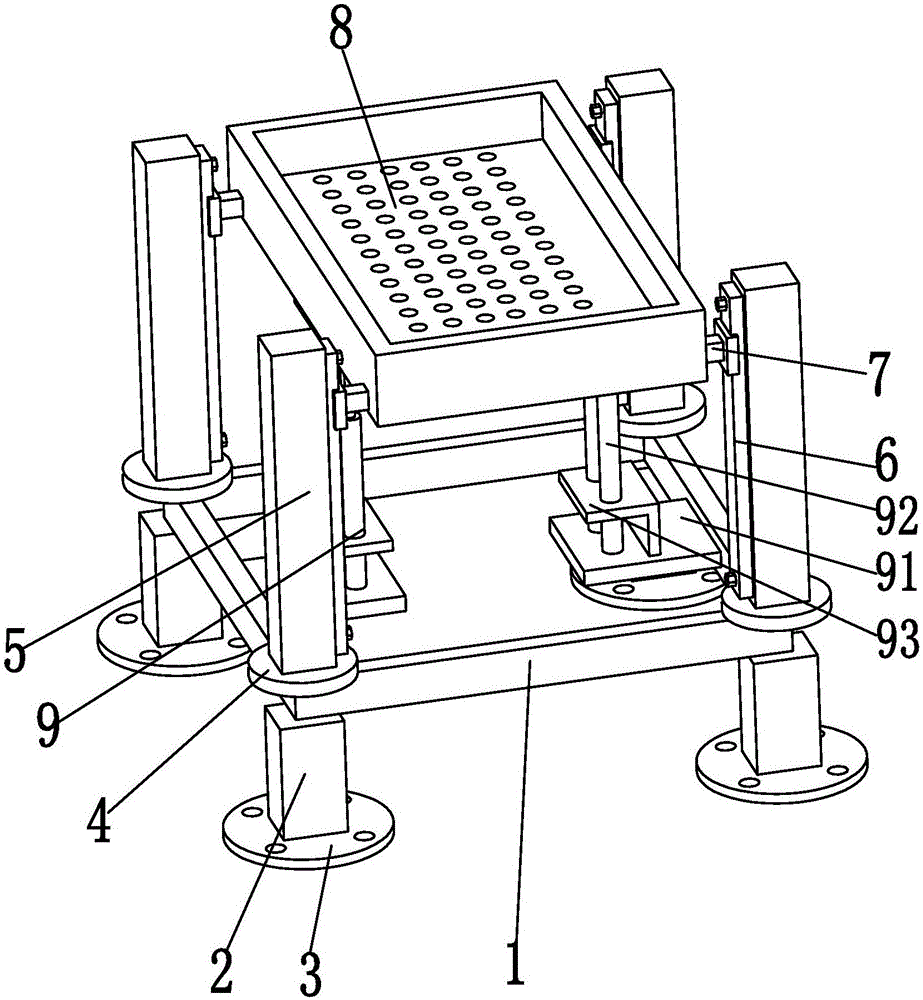

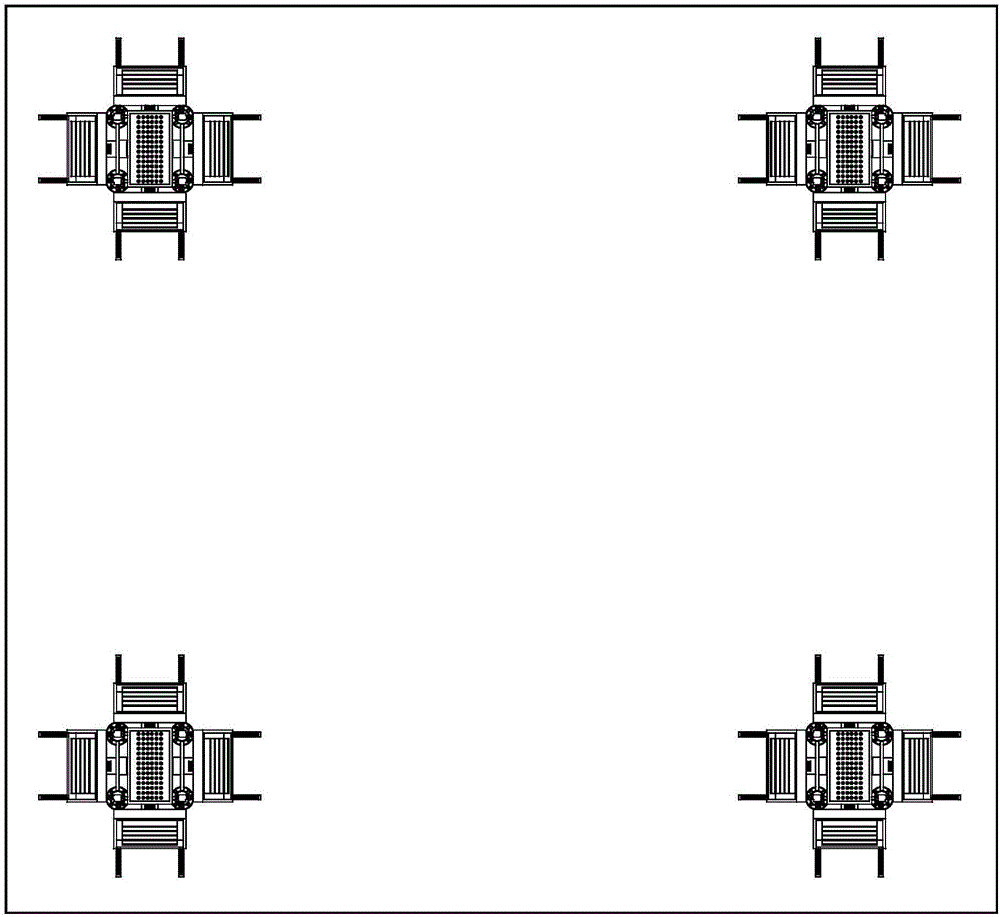

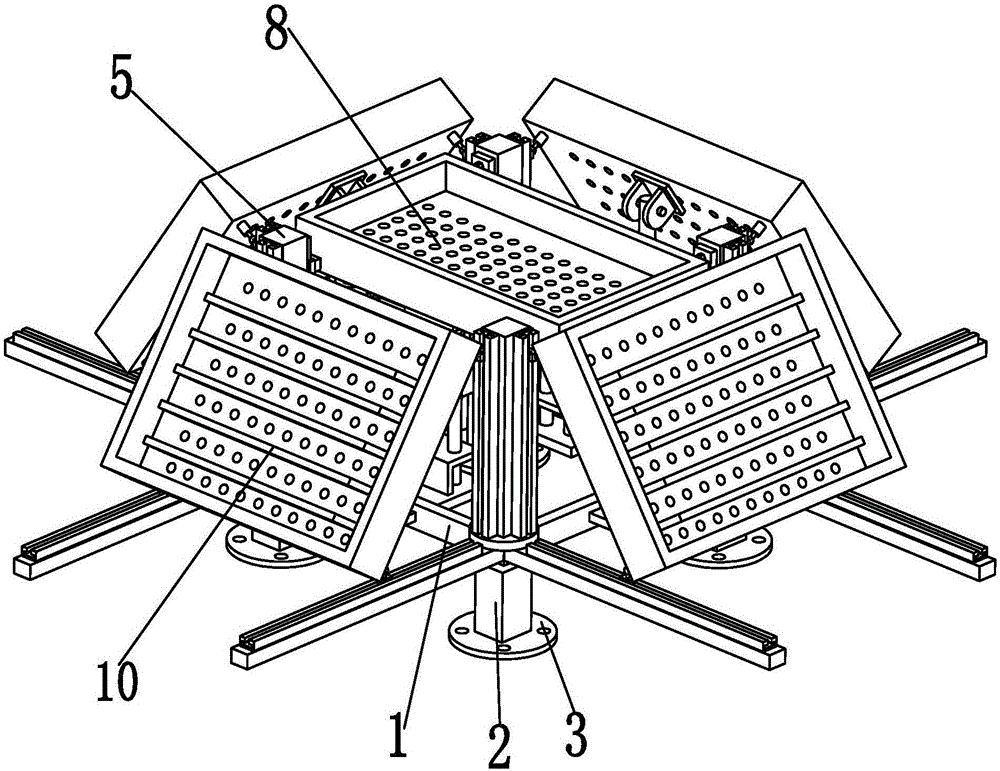

Multi-layer waterweed planting device special for lobster aquaculture

InactiveCN106508660APrevent the phenomenon of biting each otherIncrease productionAgriculture gas emission reductionCultivating equipmentsEconomic benefitsEngineering

The invention relates to a multi-layer waterweed planting device special for lobster aquaculture. The multi-layer waterweed planting device includes a square basic frame, four support feet are symmetrically welded onto the lower end of the square basic frame; four bases are symmetrically welded onto the upper end of the square basic frame; the four basic bases are welded onto four installation columns; an inner walls of the four installation columns are provided with four linear slide rails; four linear slide columns are arranged on the four linear slide rails; a planting box is welded among the four linear slide columns; first water holes are evenly formed in the center of the planting box; two lifting driving mechanisms are arranged on two sides of the lower end of the planting box; and four side surface planting branch chains are arranged on four end surfaces outside the square basic frame. The multi-layer waterweed planting device can achieve multi-layer waterweed supplying and high yield cultivation in lobster aquaculture, can automatically feed lobsters, is low in lobster aquaculture cost, is high in output value of the lobsters, is good in aquaculture effect, and is high in economic benefits.

Owner:黄江龙

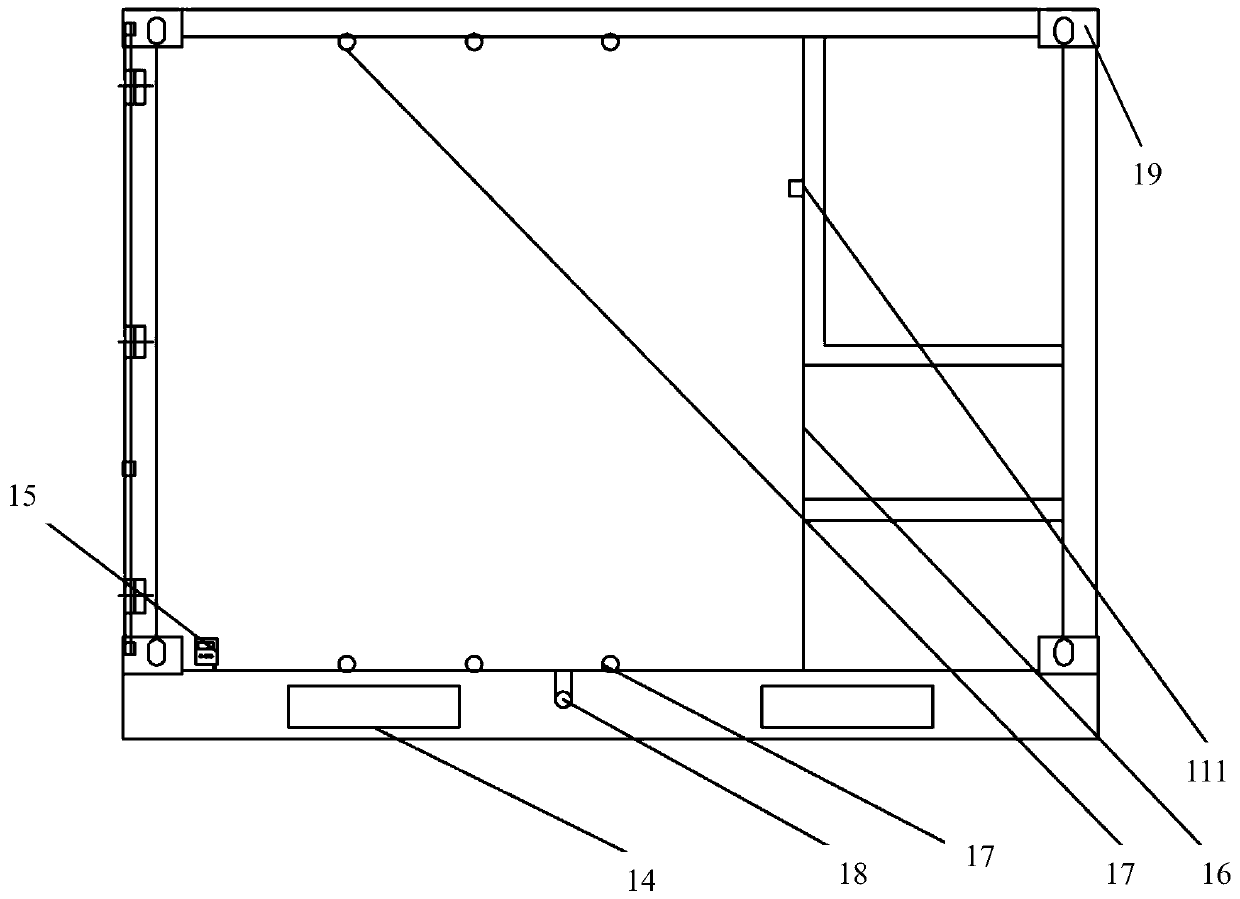

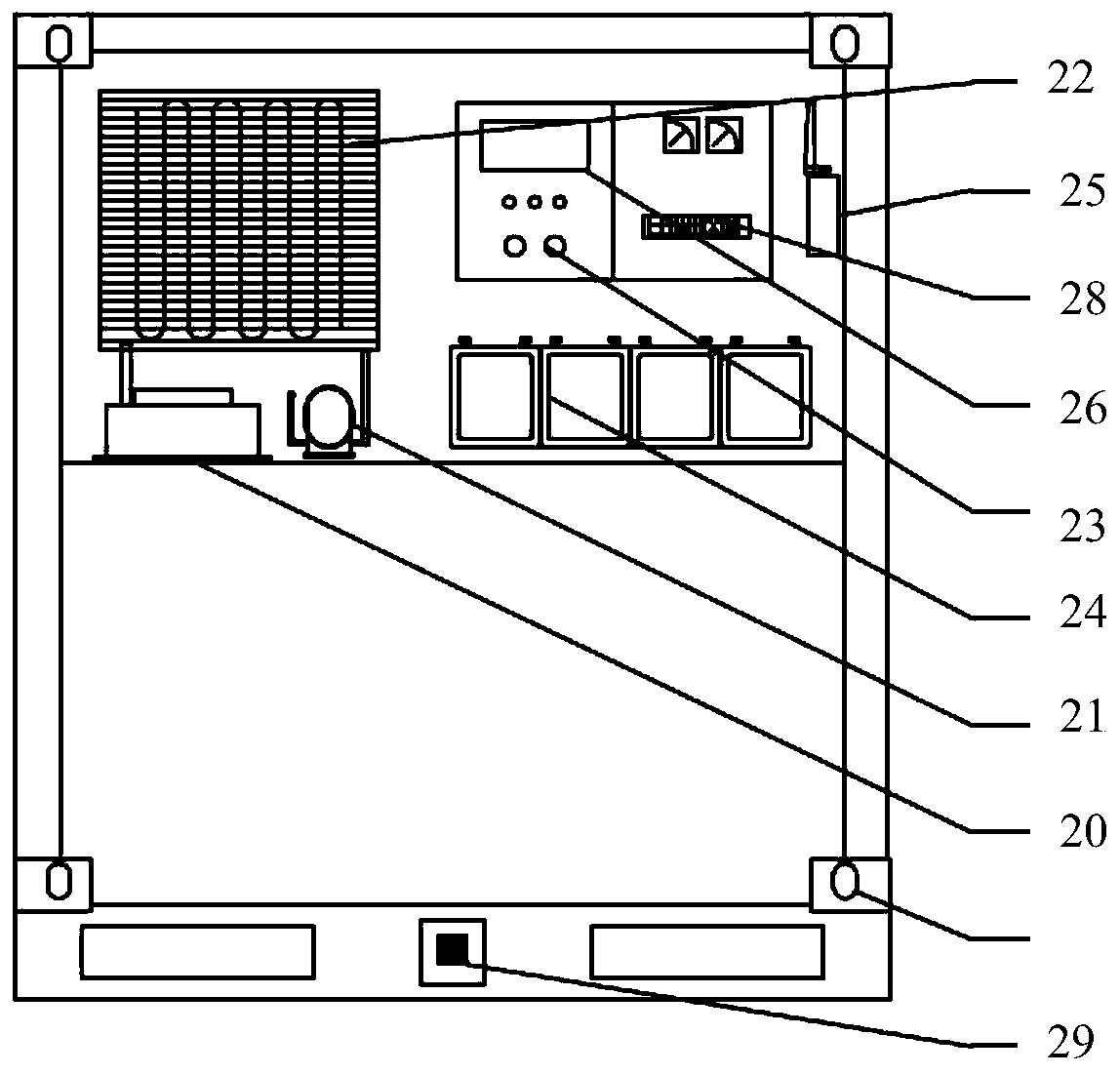

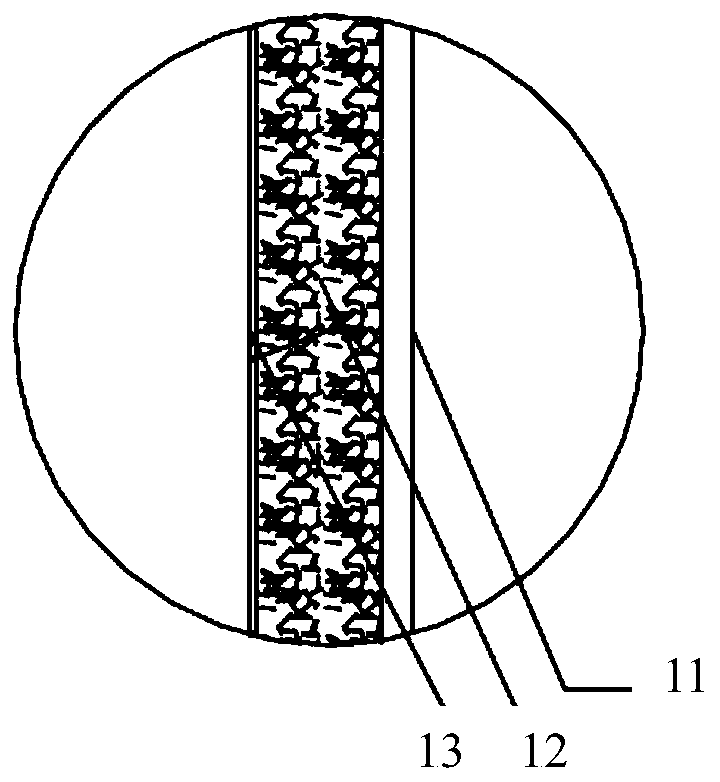

Cold chain container control system

PendingCN110515327ASolve quality problemsSolve efficiency problemsProgramme controlComputer controlCold chainControl system

The invention belongs to the field of cold chain transportation industry, and discloses a cold chain container control system. The control system comprises a heat preservation box body, a refrigeration module, a power management module, a monitoring module and a cloud platform management module. The box body stores and transports cargoes; the refrigeration module controls the temperature in the box body through heat exchange inside and outside the box body; the power management module is used for controlling the power supply mode of a power supply and supplying power to other systems in the box body; the monitoring module is used for monitoring various parameters of the box body and sending the parameters to the cloud platform management module; and the cloud platform management module isused for analyzing the received parameters and feeding back instructions to the monitoring module. The cold chain container control system is suitable for common logistics transportation, reliable inwork, efficient and convenient, and solves the problems of low transportation quality, low efficiency, low economical efficiency and the like caused by the fact that traditional cold-chain freight transportation only depends on special vehicles or heat preservation equipment.

Owner:刘师洋 +1

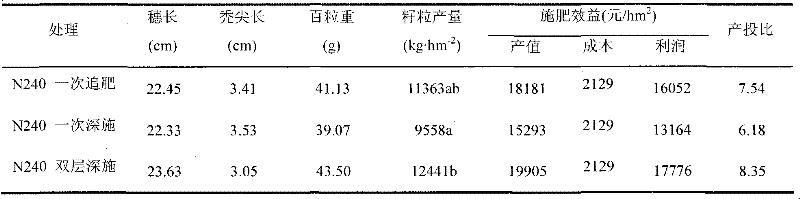

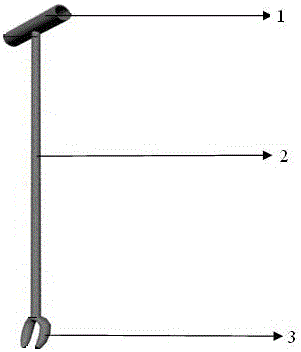

A method of high-efficiency fertilization of corn with double-layer deep application

InactiveCN102257901ASolve UtilizationSolve outputFertilising methodsHorticultureDouble fertilizationSoil surface

The invention relates to a method for high-efficiency fertilization of corn by double-layer one-time deep application, which is to divide the fertilizer into two layers according to the proportion and apply deep one-time deep application to the soil when corn is planted in spring. The proportion of fertilizers in different soil layers is as follows: 100% phosphate fertilizer + 16% ~ 19% nitrogen fertilizer is applied at 5 ~ 7cm below the surface soil, and 81% ~ 84% nitrogen fertilizer + 100% potassium fertilizer is applied at 14 ~ 15cm below the surface soil. The method can meet the nutrient demand of spring corn in the whole growth period, has the characteristics of simplicity and labor saving, and has good effects in reducing environmental pollution caused by fertilization, effectively improving fertilizer utilization rate and reducing agricultural production cost and the like.

Owner:辽宁省农业科学院环境资源与农村能源研究所

Method for intercropping lycium barbarum and honeysuckles in arid desert area

InactiveCN105993515AMake full use ofNo delay in farming operationsTransplantingPlant cultivationAridAgroforestry

The invention relates to a method for intercropping lycium barbarum and honeysuckles in an arid desert area. The method includes the following steps of 1, excavation of lycium barbarum planting furrows; 2, excavation of intercropped honeysuckle planting furrows; 3, seedling selecting, wherein one-year-old lycium barbarum seedlings without disease and pest damage and one-year-old honeysuckle seedlings without disease and pest damage are selected; 4, planting, wherein after soil is unfrozen in spring of the next year, the lycium barbarum seedlings and the honeysuckle seedlings are pulled up and then immediately planted through a seedling planting device; 5, field management. According to the method, as the lycium barbarum and the honeysuckles are intercropped, reciprocal symbiosis of the reciprocal symbiosis and the honeysuckles under the arid desert condition can be achieved, the problems that when only the lycium barbarum is planted, benefits are single, and the survival rate of plants is low are solved, organic unification of ecological benefits, economic benefits and social benefits of desert governing is achieved, and technical supports are provided for safe and efficient agricultural yielding of the arid desert area accordingly.

Owner:GANSU UNIV OF CHINESE MEDICINE +2

Biological organic bait containing ferment bacteria for bighead carp and method for preparing same

InactiveCN1969658AImprove the status quo of low productionAdjust the farming structureFood processingClimate change adaptationBiotechnologyAdditive ingredient

The invention relates to an enzymatic bacterial organic bait for bighead carp and process for preparation, wherein the bait is prepared from enzymatic bacterium, distiller's grain meal, glutamate dregs, oil dregs, vegetable waste, soybean waste, wheat bran, fish meal, maize flour, bone meal, microelements and mineral elements, by a predetermined weight ratio through steps of proportioning, disintegrating, mixing homogeneously, fermenting and disinfecting, drying, detecting and packaging.

Owner:武汉合缘绿色生物股份有限公司

Environment-friendly prevention and treatment method of plant diseases and insect pests of Shatian pomelo

The invention discloses an environment-friendly prevention and treatment method of plant diseases and insect pests of Shatian pomelo. The environment-friendly prevention and treatment method comprises: according to a change principle of year-round propagation and growth of the insect pests of the Shatian pomelo and natural enemies of the plant diseases and insect pests, dividing year-round work into: garden cleaning after harvesting, garden cleaning for the second time from December to February of the next year, first-time peak of the plant diseases and insect pests from March to June, stable natural enemy population from July to September, and enhancement of management of Shatian pomelo planting at phases of protecting and utilizing the natural enemies and the like from October to November. In a management process, a prevention and treatment period is selected and pesticides are scientifically utilized; the insect pests are controlled and the natural enemies are also protected; and the effect of controlling the insect pests of the natural enemies is sufficiently expressed so that the aims of treating the insect pests through beneficial insects and treating the insect pests through bacteria are realized, and the environment-friendly prevention and treatment method is environmentally friendly and effective.

Owner:李德新

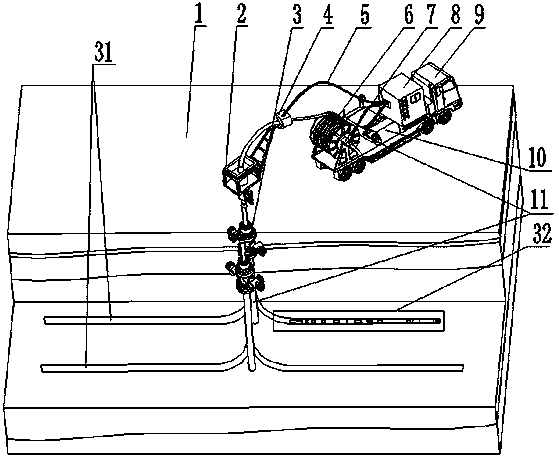

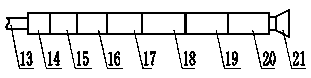

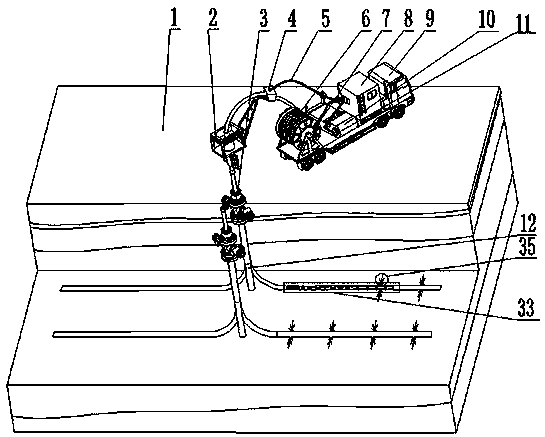

Robot-adopting explosive hydraulic compound fracturing drilling and completion system for hot-dry rocks

ActiveCN108729896ASolve the costSolve the poor effect of fracturingFluid removalDirectional drillingClosed loopData acquisition

A robot-adopting explosive hydraulic compound fracturing drilling and completion system for hot-dry rocks comprises a ground control system, a robot, a drilling execution system, an explosive fracturing execution system, a hydraulic fracturing execution system, a directional execution system and a reentry execution system. The ground control system comprises a data processing center, a ground dataacquisition sensor, a well drilling completion controller, a ground signal transmitting-receiving device, a blowout preventer, a continuous oil pipe well mouth device, a continuous oil pipe operationtruck, an input device and a storage unit. The robot comprises a well bottom data acquisition sensor, a CPU, a drilling control module, a well bottom signal transmitting-receiving device, a reentry tool control module, a directional tool control module, an explosive fracturing control module and a hydraulic fracturing control module. By adopting the robot technology, intelligent closed-loop welldrilling is achieved, the operation cost is effectively reduced, a burning explosion and a hydraulic compound fracturing technology are adopted, a hot-dry rock fracture network can be remarkably optimized, and the risk of 'heat transfer short circuit' is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

Method for treating desert cistanche seeds

ActiveCN103039159ASolve the low vaccination rateSolve benefitsBiocidePlant growth regulatorsDiseaseAnti freezing

The invention discloses a method for treating desert cistanche seeds. The method is characterized in that the raw material medicines comprise an inductive agent, 1-chloromethylsilatrane, Vc and a gibberellin solution. The method has the beneficial effects that the medicine seeds are soaked by using the inductive agent, and anti-freezing, drought resistance, water resistance, cold resistance, light resistance and antioxidant genes of plants are integrated, so that roots of plants are deep and are shortened, disease and cold resistance and insect resistance and repelling are realized; the emergence rate of the cistanche seeds is increased, the root system is prompted to be developed, the root capacity is increased, and problems of low inoculation rate and low benefit in desert industrial and scale development of cistanche in different places at present are effectively solved.

Owner:叶文明

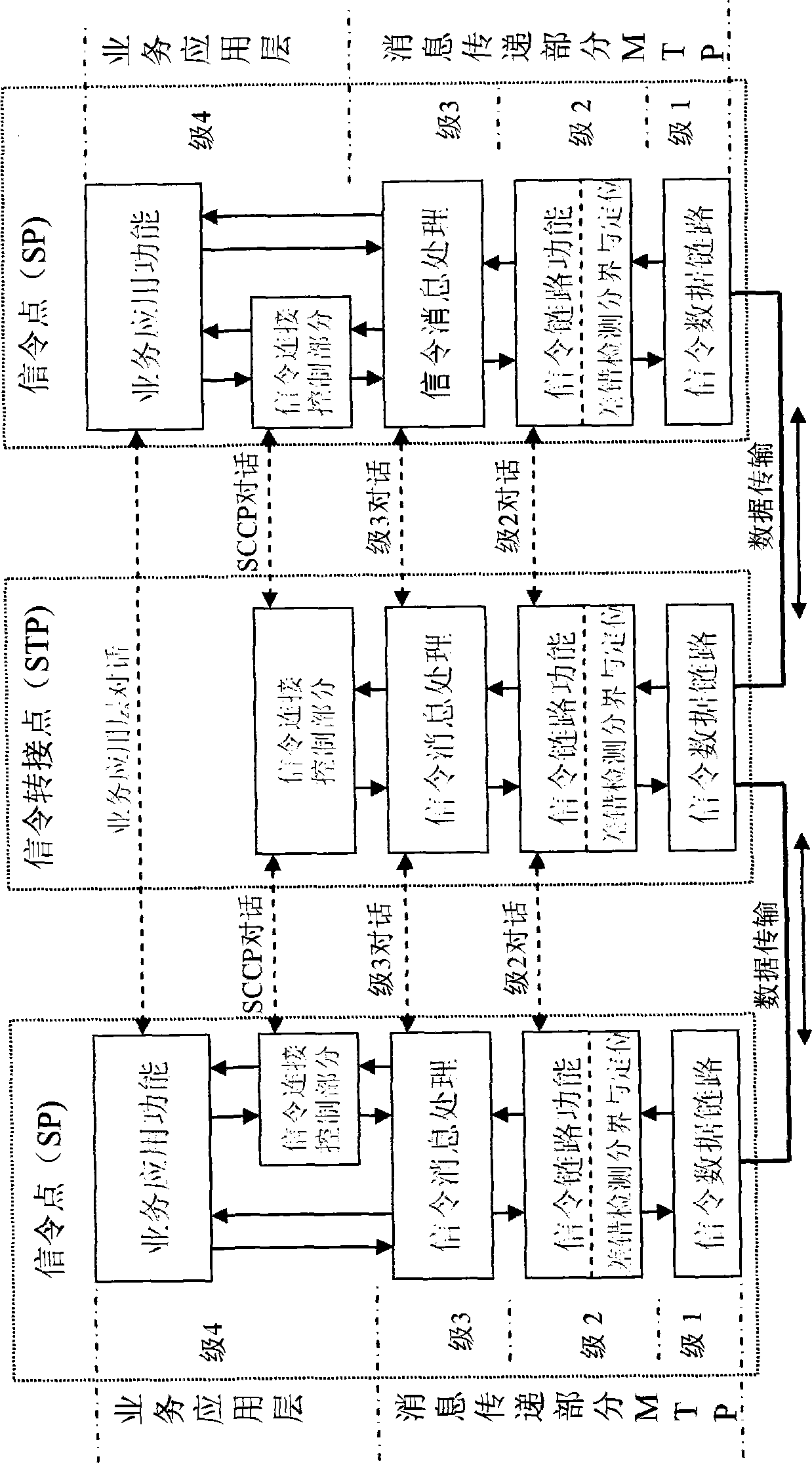

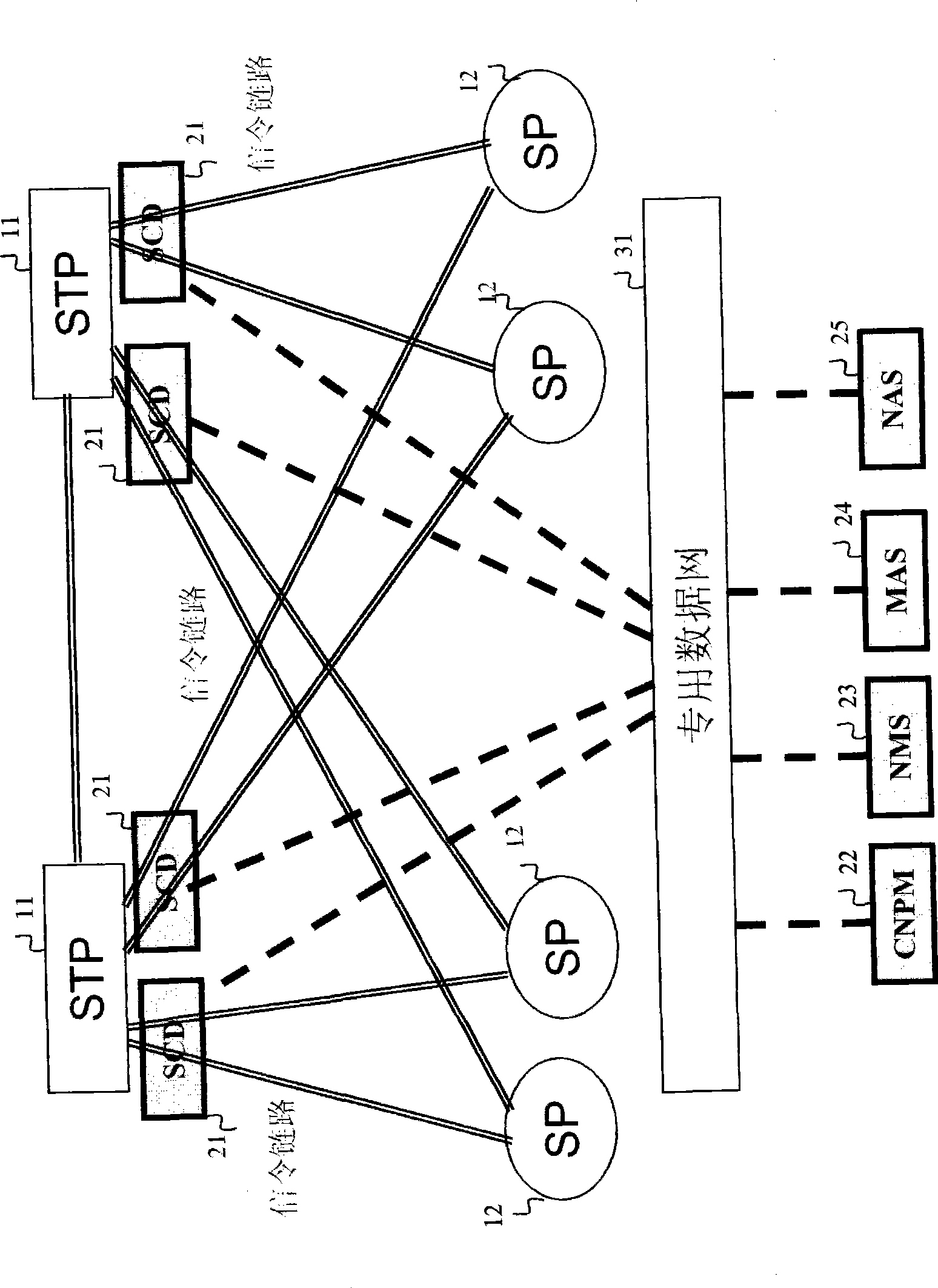

System for implementing telecom value added business based on signaling processing technology

InactiveCN101472197AEfficient handlingEfficient deliverySpecial service for subscribersSelection arrangementsIntelligent NetworkService control

The invention relates to a system based on the signaling processing art for realizing the telecom value-added service. The system comprises a plurality of service control devices accessed in a No 7 signaling network and a service management server. The service control device organically applies the processor art and the decentralized data table art to a communication network, and ingeniously utilizes the message-passing ability and the internal high-reliability characteristics of the No 7 signaling network, and provides two signaling link access modes to realize the query about a memory service data sheet and the execution service logic, wherein, the access modes are a signaling terminal mode with signaling points and a signaling transfer mode without signaling points, so that the high-effective processing and transferring of the signaling information are realized. The invention breaks the confines of the traditional exchange and the intelligent network art, implements the services, such as the user service authentication, the number portability, the signaling monitoring, and the like, in a large scale, effectively solves the contradictions between investment and benefit, and technology and development, and is dependent of the prior communication network.

Owner:SHANGHAI LIANGJIANG COMM SYST

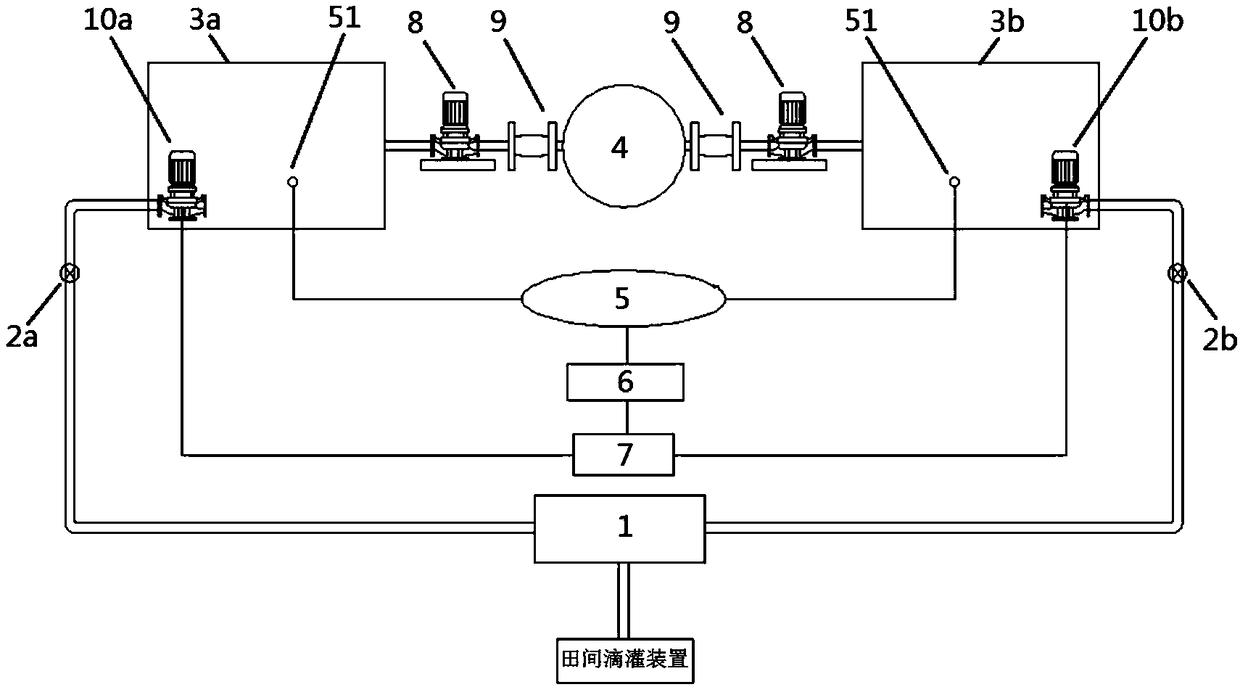

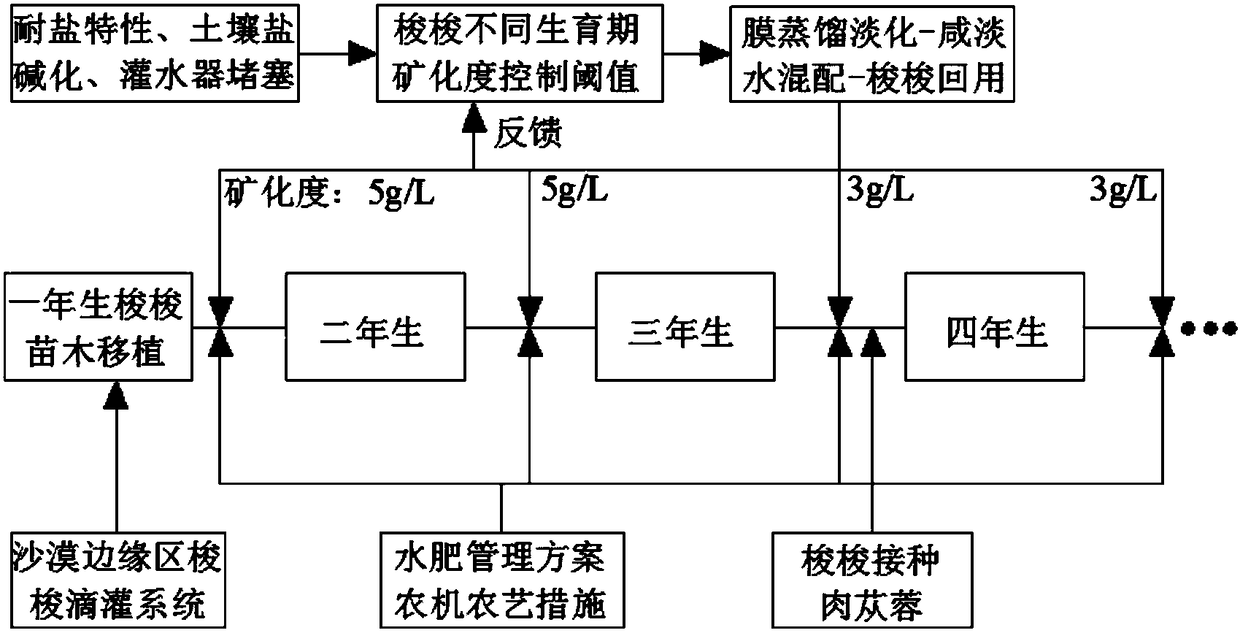

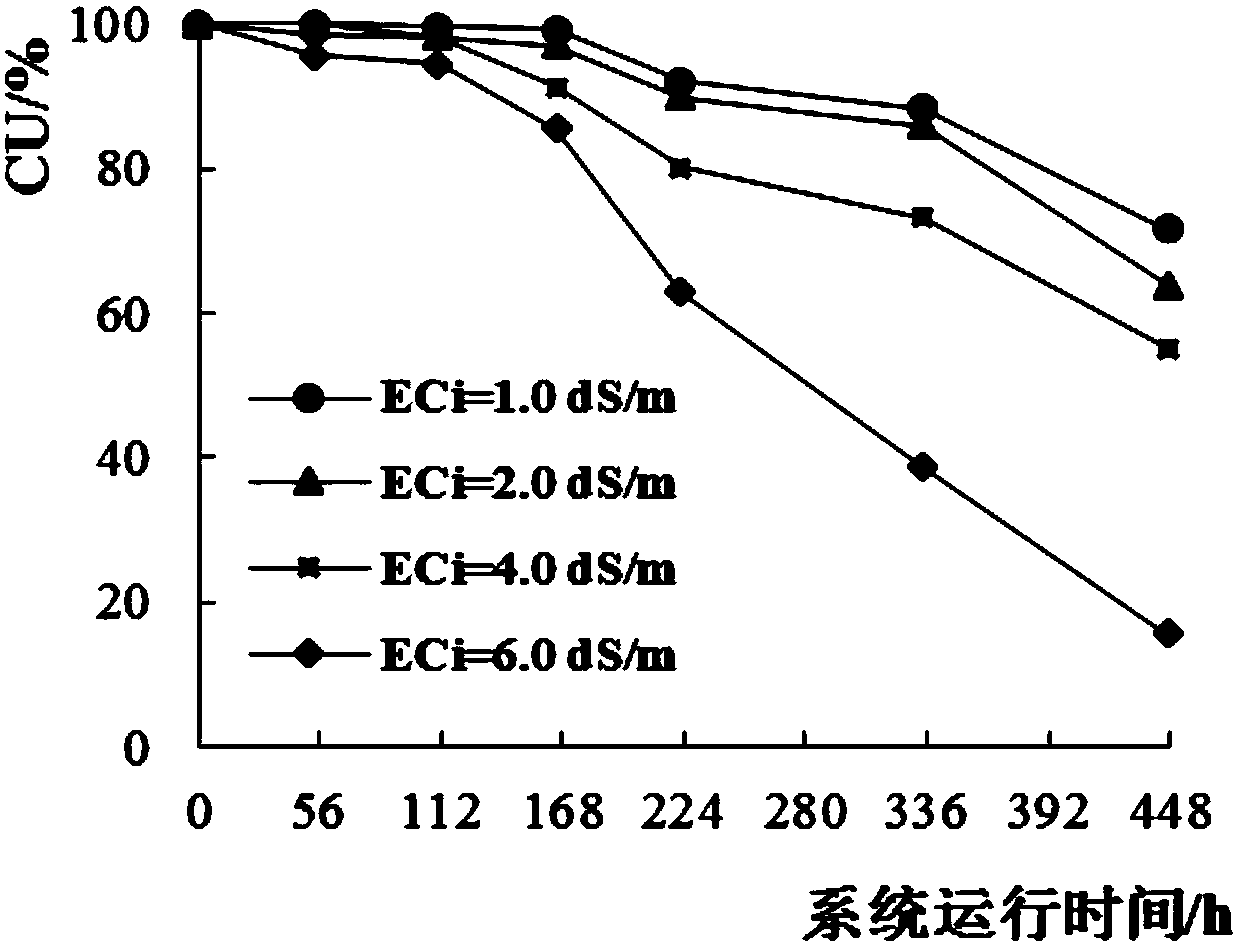

Drip-irrigation system for Haloxylon ammodendron in desert marginal area, and planting method and application for Haloxylon ammodendron

InactiveCN108464225ASolve the problem of energy consumptionSolve the costClimate change adaptationWatering devicesHaloxylon ammodendronWater source

The invention relates to a drip-irrigation system for Haloxylon ammodendron in a desert marginal area, and a planting method and an application for the Haloxylon ammodendron, belonging to the technical field of drip irrigation. The drip-irrigation system comprises a first reuse device and a field drip-irrigation device, wherein the first reuse device is connected with the field drip-irrigation device through a water delivery pipeline; through the first reuse device, an underground water source in the desert marginal area is distilled, and brackish water and fresh water obtained from distillation and separation are mixed into brackish-fresh mixed water in proportion; and the brackish-fresh mixed water is delivered to the field drip-irrigation device through the water delivery pipeline. Thedrip-irrigation system provided by the invention comprehensively considers salt tolerance of the Haloxylon ammodendron, clogging of an irrigation emitter and secondary salinization of soil under the condition of drip irrigation with brackish water, provides the control range of the salinity of irrigation water in different growth stages of the Haloxylon ammodendron, and solves the problems of over-high energy consumption and cost and low degree of automation for a conventional brackish-water desalination technology on the basis that the problems of root wilting of the Haloxylon ammodendron, clogging of the irrigation emitter and secondary salinization of the soil due to irrigation with high-salinity brackish water are solved.

Owner:CHINA AGRI UNIV

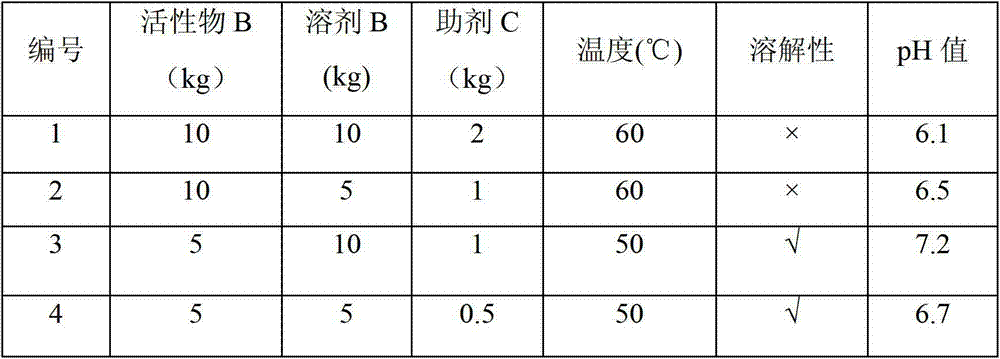

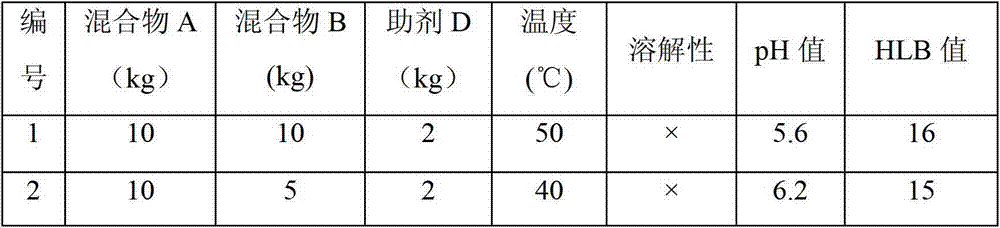

Water emulsion type L40 surface active agent

The invention relates to a water emulsion type L40 surface active agent. A preparation method of the water emulsion type L40 surface active agent comprises the following steps: mixing an active matter A with a solvent A based on the weight ratio of 10: 10 so as to obtain a mixture A; mixing an active matter B with a solvent B and an assistant C based on the weight ratio of 10: 10: 1 so as to obtain a mixture B; mixing the mixture A with the mixture B and an assistant D based on the weight ratio of 6: 5: 2; and homogenizing and uniformly mixing so as to obtain the water emulsion type L40 surface active agent. The water emulsion type L40 surface active is high in quality and relatively low in comprehensive cost, can be widely popularized, and is low in dosage, so that down-stream products are excellent in performances and remarkable in economic benefit. By adopting the water emulsion type L40 surface active agent, the problems that the cost of preparing pesticide is high, serious pollution is brought to the environment, and the benefit is low, can be solved, and furthermore, the residual toxicity of the crops can be effectively degraded, the application of pesticide for the crops is improved, the rain resistance and the drought resistance of the crop can also be improved; and the water emulsion type L40 surface active agent plays an important role in updating the promotion of surface active agent products, realization of increase crop production and income of farmer, and reduction of the pollution of pesticides products to the environment.

Owner:TRUST CROP PROTECTION TECH CO LTD

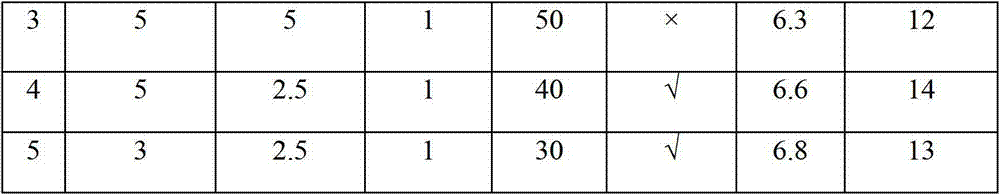

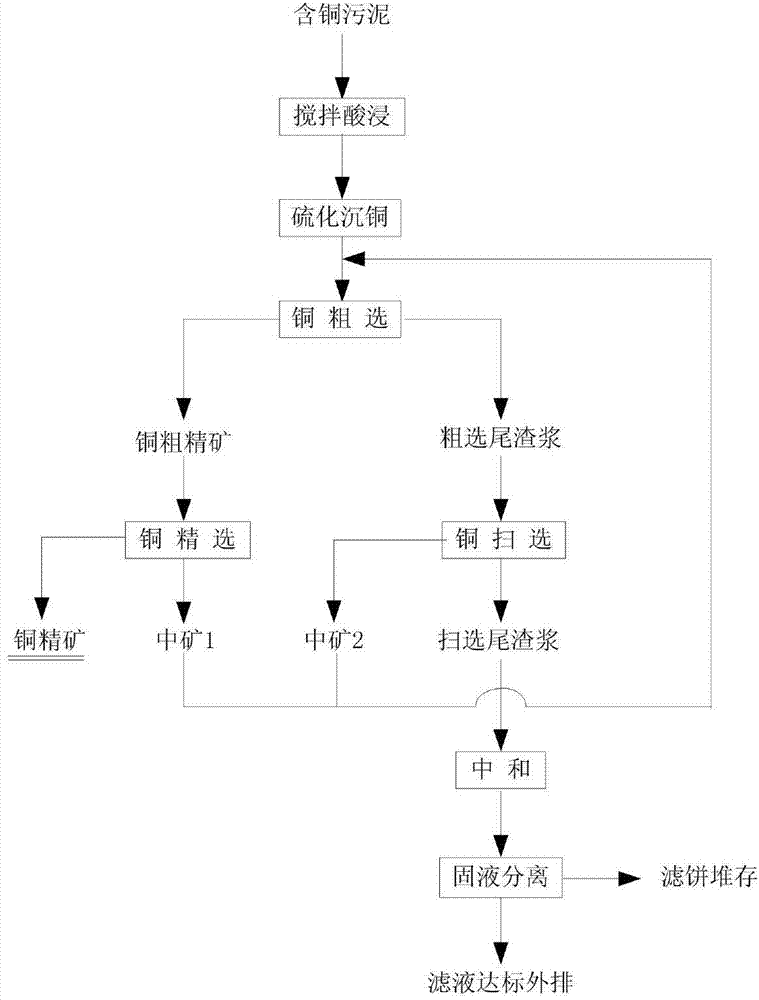

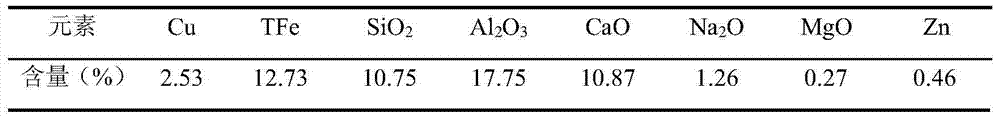

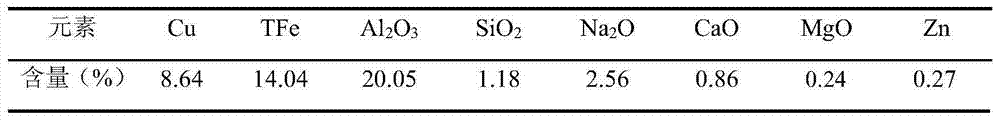

Method for using copper-containing sludge to produce copper concentrate

ActiveCN104726700AResolve separabilityImprove washing effectProcess efficiency improvementSludgeSlurry

The invention relates to a method for using copper-containing sludge to produce copper concentrate. The method includes: intermittently adding acid, controlling the pH of solution of the whole reaction process to be about 2.5, and reacting for about 100 minutes to obtain stirring acid leaching residue slurry; adding sodium sulfide solution into the stirring acid leaching residue slurry, and stirring for about 15 minutes to obtain vulcanized electroless plating copper residue slurry; adding about 12g of butyl xanthate serving as a collecting agent and about 13g of ammonium dibutyl dithiophosphate into each cubic meter of the vulcanized electroless plating copper residue slurry, stirring for 3 minutes, adding 2g of 2# oil serving as a foaming agent, continuing stirring for 2 minutes, and then roughing for 6 minutes to obtain rough copper concentrate and roughing tailing slurry; concentrating the rough copper concentrate for 5 minutes to obtain copper concentrate and middlings 1, adding 5g of butyl xanthate serving as the collecting agent and 5g of ammonium dibutyl dithiophosphate into each cubic meter of the roughing tailing slurry, stirring and scavenging to obtain middlings 2 and scavenging tailing slurry; adding lime milk to neutralize the scavenging tailing slurry, stirring for 50 minutes and controlling end point pH to be 8, and performing solid-liquid separation after reaction to obtain filtrate and filter cakes. The method is simple in production line and production process, low in total production cost, low in investment, fast to achieve desired results, low in energy consumption, high in copper recycling rate, and the like.

Owner:ZIJIN MINING GROUP

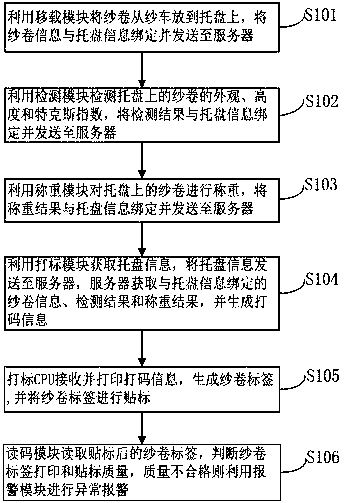

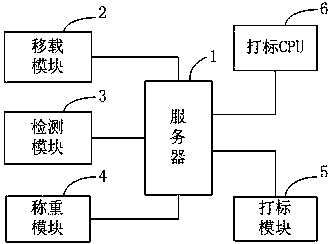

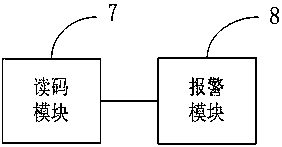

Yarn coil automatic marking method and system

InactiveCN110589160AAvoid mistakesSolve efficiency problemsLabelling machinesYarnElectrical and Electronics engineering

The invention discloses a yarn coil automatic marking method. The yarn coil automatic marking method comprises the following steps: yarn coils are placed on trays by using a transfer module; the appearance, heights and Tex indexes of the yarn coils are detected by using a detecting module; the yarn coils are weighed by using a weighing module, and yarn coil information, detecting results and weighing results are bound with corresponding tray information and sent to a server; the tray information is obtained through a marking module, and is sent to the server; the server obtains the yarn coil information, detecting results and weighing results bound with the tray information, and generates coding information; a marking CPU receives and prints the coding information to generate yarn coil labels for labeling; a code reading module reads the bonded yarn coil labels to judge the yarn coil label printing and labeling quality; and when unqualification is judged, the abnormal alarm is given. The invention further provides a yarn coil automatic marking system. The problem of influence on the production efficiency and the economical benefit by low manual marking efficiency, weak marking quality and easy generation of errors in marking of multiple types of yarn coils is solved.

Owner:四川长虹智能制造技术有限公司

Ginseng dormancy-free facility cultivation method

ActiveCN106888798AProtect wild resourcesResolution cycleSeed and root treatmentClimate change adaptationRoom temperatureControl room

The invention provides a ginseng dormancy-free facility cultivation method. The method mainly includes following steps: soaking rhizome of ginseng in a gibberellin solution for 2-6h; cultivating a ginseng plant in a matrix; supplementing light for 7-12h each day, controlling room temperature to higher than 18 DEG C, and harvesting after maturing. The cultivation method is simple and convenient to operate, can be realized without professional personnel and is comparatively mild in operation condition; facility cultivation technology is adopted for dormancy-free cultivation of ginseng, so that growing period of ginseng is shortened greatly; ginseng of two years old can be harvested after going through facility cultivation for 2-3h, and yield of ginseng of two years old is equivalent to that of ginseng of 4-6 years old after going through common facility cultivation; an operation route which is more novel is provided for the ginseng cultivation method, and the cultivation method is worthy of large-scale popularization and application and fills related technical vacancy.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Soybean coating strip planting method

InactiveCN103026872ARaise the Equivalence RatioIncrease productionPlant protective coveringsAgricultural engineeringEconomic benefits

The invention discloses a soybean coating strip planting method. The specific operation method is that (1) in a soybean coating strip planting mode, strip width is 1.6 millimeters, and soybean strip width is 70 centimeters; (2) a coating bunch planting method is adopted by the soybean strip, namely, soil preparation and film laying are firstly conducted, brute force ultramicro films with breadth 60 centimeters and thickness between 0.005 millimeter and 0.007 millimeter are selected so that a raised path can not be produced in the process of coating, the films are laid flat on the ground, membrane surface is 50 centimeters, space between the films is 20 centimeters, six lines of soybeans are planted by a coating bunch planting machine on each film, hill spacing is 11 centimeters in average, three to six grains of soybeans are planted in each hill, and film holes are sealed timely after soybeans are planted; and (3) three lines of soybean strips are planted once by using three lines of sowing machines, and line spacing is 30 centimeters. The soybean coating strip planting method is notable in production and effect increase effects and convenient to operate. Various technology links can be finished easily with the help of existing farming machinery. Natural resources can be utilized completely to a large extent, ability for resisting and defending natural hazards such as a drought is improved, yield per unit area is improved, and economic benefits of grain and soy crop plantation for peasants are guaranteed.

Owner:宋必成

Establishing method of multilayer ecological lobsterling breeding system

ActiveCN106305559APrevent the phenomenon of biting each otherIncrease productionClimate change adaptationPisciculture and aquariaShrimpEconomic benefits

The invention relates to an establishing method of a multilayer ecological lobsterling breeding system. The establishing method comprises the following steps that step one, lobsterling breeding pond selection is performed; step two, water plant planting is performed: a rice field is selected as a lobsterling breeding pond, a bamboo fence with the height of 30-34 cm is arranged around the lobsterling breeding pond, and a plurality of water plant planting devices for water plant planting are evenly installed on the lobsterling breeding pond at intervals; step three, a fertilizer is sowed; step four, lobsterlings are put; step five, feeding is performed; step six, separated lobsterling breeding is performed: after the lobsterlings are bred for a period of time, the lobsterlings grow into adult lobsters for breeding, and then separated lobsterling management is conducted on the bred lobsterlings and the adult lobsters in the lobsterling breeding pond; step seven, lobster management is performed. The establishing method can achieve a high-yield lobsterling breeding function and has the advantages of automatic lobsterling feeding, low lobsterling breeding cost, high lobsterling production value, good breeding effect, high economic benefits and the like.

Owner:南京螯龙现代农业科技研究院有限公司

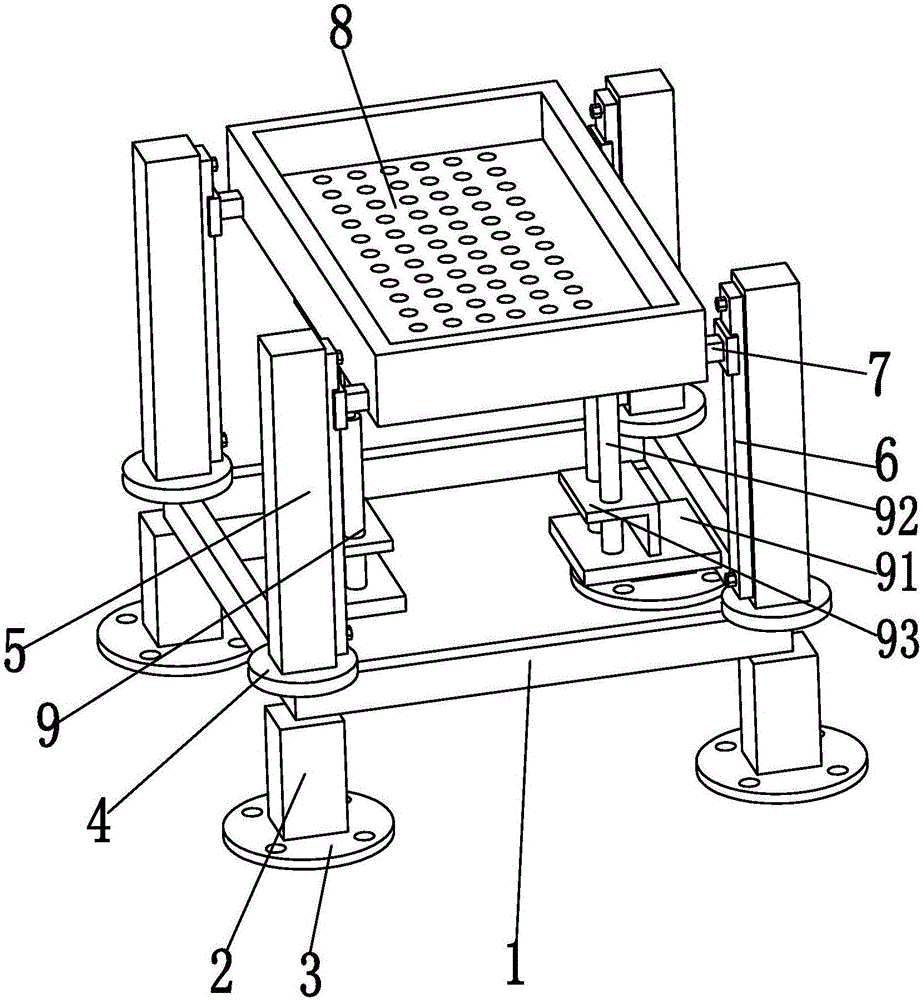

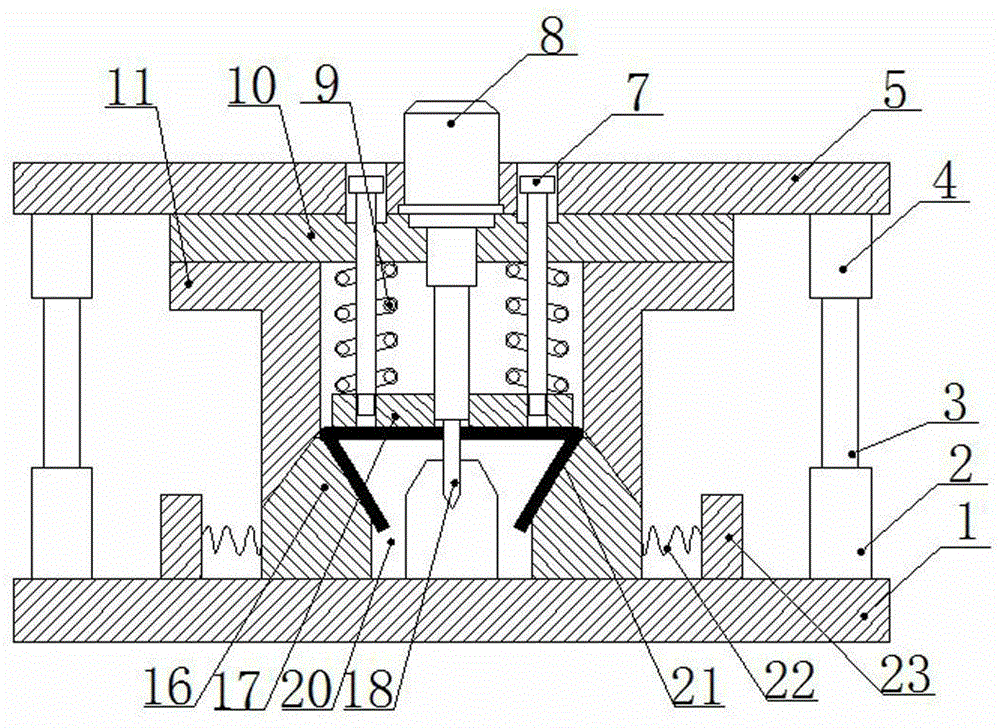

V-shaped bracket blanking and bending die

InactiveCN104907411AIncrease productivityUse less process equipmentShaping toolsEconomic benefitsEngineering

Owner:CHENGDU RUIDA KEHENG TECH

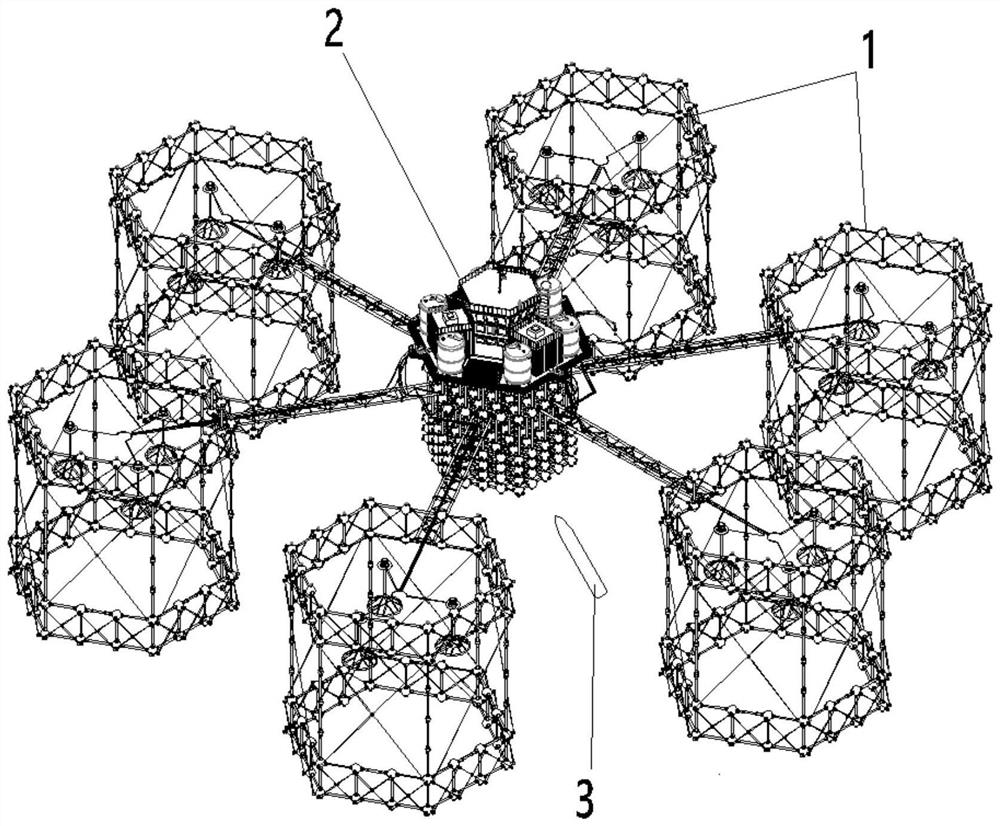

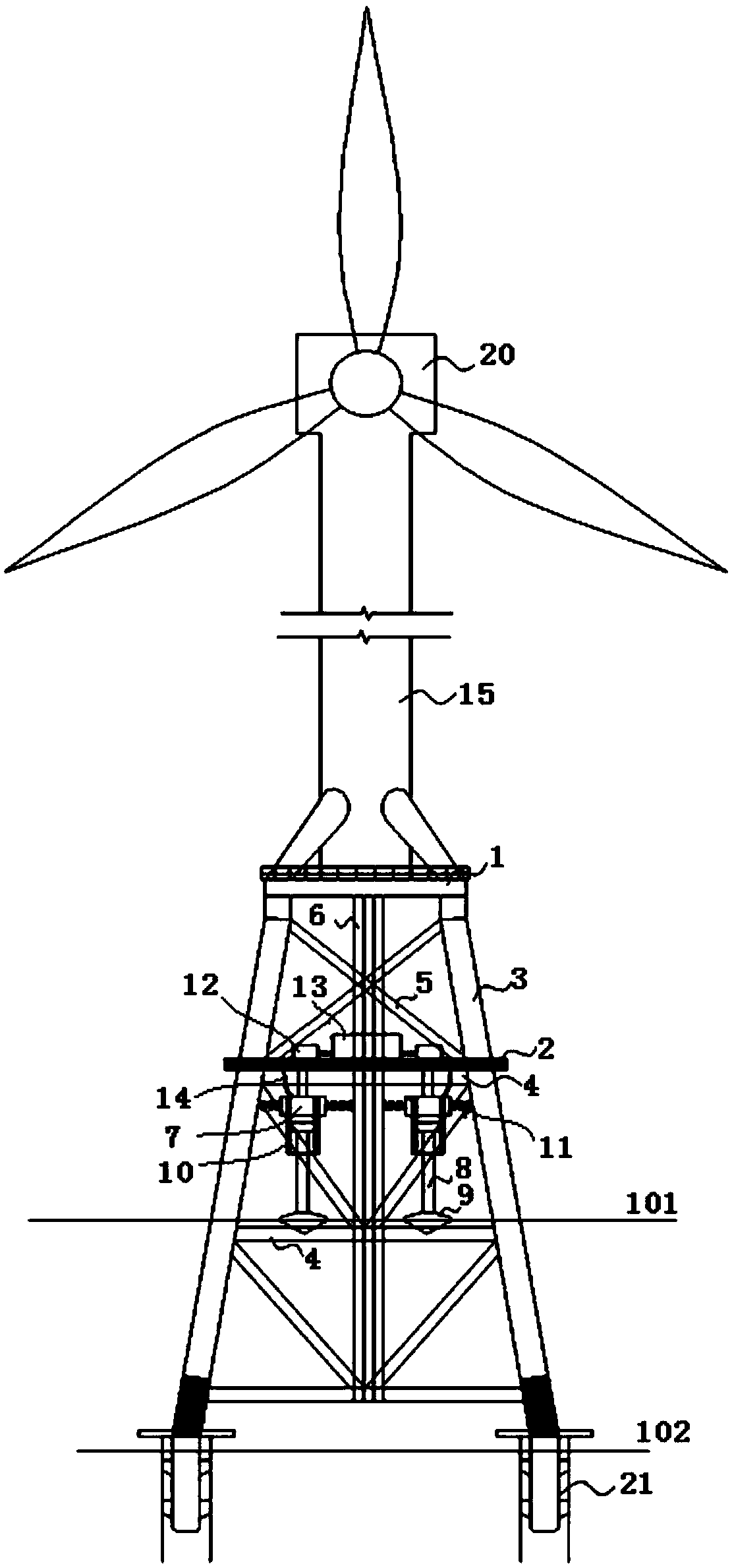

Pelagic cage culture complex

PendingCN111919802ASolve the \"anti-wind and wave\"Solve benefitsClimate change adaptationPisciculture and aquariaCold chainMarine engineering

The invention discloses a pelagic net cage culture complex. The complex is characterized by comprising pelagic culture net cages with a modular space truss structure, a floating service ocean platformand a working ship; the pelagic culture net cages are arranged around the floating service ocean platform, and the working ship performs transportation between the shore and the floating service ocean platform back and forth; a lower buoyancy structure of the floating service ocean platform is formed by modularly stacking buoyancy modules with array buoyancy adjustable points, and an upper platform structure provides storage spaces for various functional modules, such as feeding fodder, materials, cold chains and living facilities; and the pelagic culture net cages are of a modular space truss structure, and solve the problems of stormy wave resistance and benefit generation. The working ship moves back and forth between the shore base and the floating service ocean platform at intervalsto transport feed, energy, equipment and supply for the platform and human resources or travelers.

Owner:澳大利亚海洋技术开发有限公司

Cultivation method for interplanting early season rice with Chinese yams

InactiveCN107548904AEarlier planting timeEarly productionCultivating equipmentsRice cultivationContinuous croppingAdditive ingredient

The invention relates to a cultivation method for interplanting early season rice with Chinese yams. The method comprises the steps of land selection and preparation, variety selection, seed soaking and germination accelerating of Chinese yam seeds, sowing, enough Chinese yam base fertilizer application, field management, harvesting and the like. By means of the characteristics that early season rice plants are short and upright and the light requirements of the seedling stage after sowing is conducted on the Chinese yams are low, scientific and reasonable internplanting is conducted on the early season rice and the Chinese yams, the problems that pest and disease damage is caused by continuous cropping, so that the Chinese yam yield is low, and the quality is poor are solved, the yield can be increased, the early season rice and the Chinese yams can come into the market in advance, and the good economic benefit is obtained; field management is conducted in the mode of combining intertillage weeding, topdressing and pest and disease damage control is adopted, reasonable nutritional ingredients can be provided for the early season rice and the Chinese yams, and meanwhile the pest and disease damage control effect is achieved; the control effect is significant, and the phenomenon that chemical pesticide is used for treatment is avoided.

Owner:桂平市金田镇旷福淮山种植专业合作社

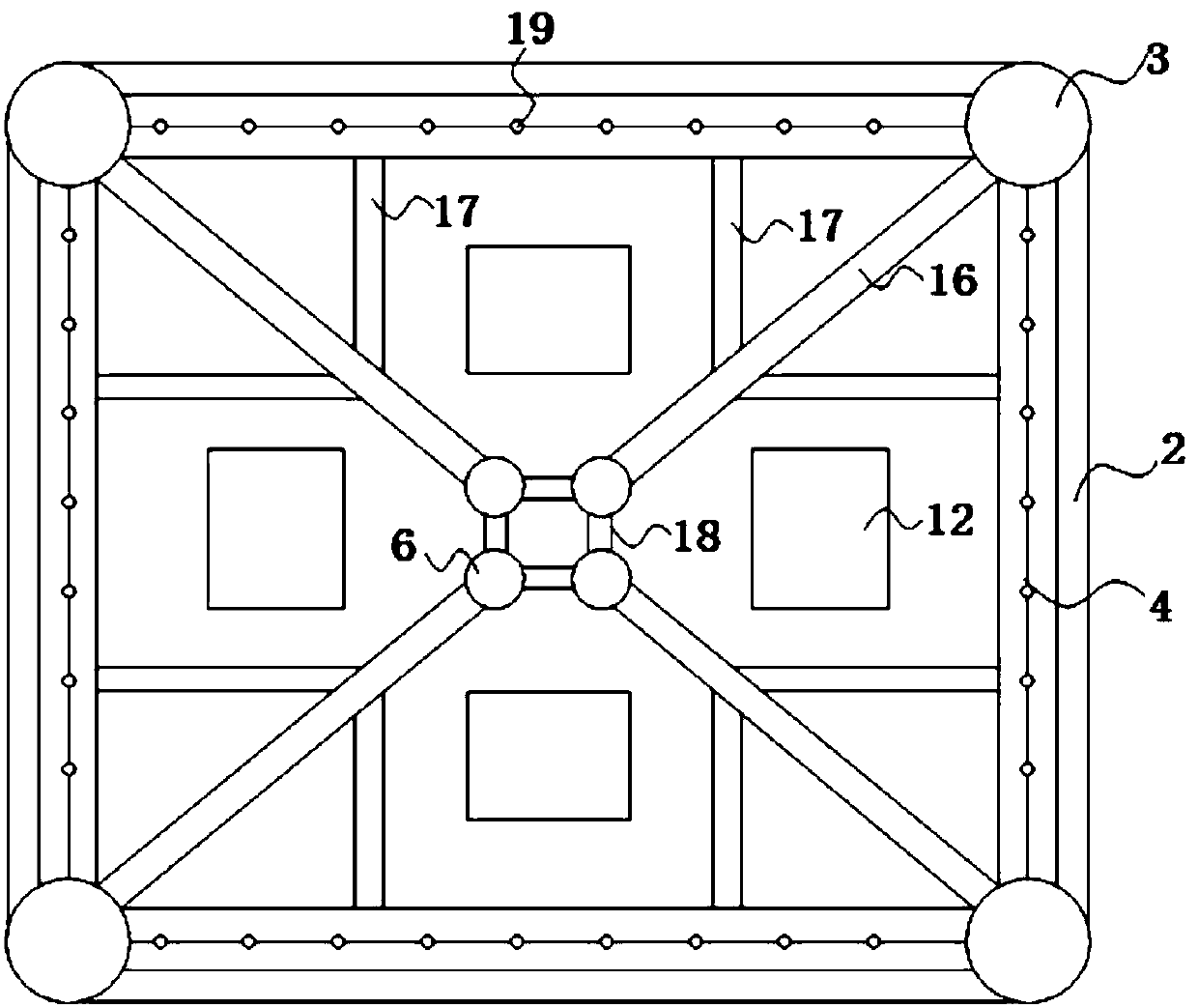

Wind and wave energy combined power generation device based on guide tube frame foundation

PendingCN109653960AImprove structural stabilityIncrease profitWind energy with water energyWind motor supports/mountsWind drivenEconomic benefits

The invention relates to a wind and wave energy combined power generation device based on a guide tube frame foundation. The combined power generation device comprises a main pile leg, the guide tubeframe foundation, a wind energy power generation platform, a wind power generation device, a wave energy power generation platform and a wave energy power generation device, wherein the wave energy power generation platform is arranged above the water, and a floater of the wave energy power generation device floats on the water. The guide tube frame foundation is used as a support structure, and aguide tube frame has excellent structural stability and is used as the support structure of a wind driven generator and a wave driven generator, so that the utilization rate of the guide tube frame foundation is increased, the problems of high cost of the support structure of the wave energy power generation device and low economic benefit of single power generation are solved, the overall generation efficiency is improved, and the effect of high feasibility is achieved on economy and structural safety.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Method for improving early benefits in thin-shell pecan orchard

InactiveCN110432064AIncrease the opening areaIncrease the exposed areaLeaf crop cultivationCultivating equipmentsFarmyard manureLayer thickness

The invention relates to the technical field of thin-shell pecan planting, in particular to a method for improving the early benefits in a thin-shell pecan orchard. The method includes the following steps: (1) garden selection: selecting soil pH value between 7 and 8 and soil layer thickness over 1 meter; (2) variety selection; (3) soil modification and preparation: removing miscellaneous trees and weeds in the garden and preparing soil according to the conditions of the garden; (4) field planting: the plant row spacing of pecan is (4-8)m* (8-12)m, digging field planting holes according to theplant row spacing, wherein the amount of rape seeds sown per mu in the orchard is 0.25-1.0kg; (5) water and fertilizer management: applying sufficient organic fertilizers or farmyard manure to the bottoms of the planting holes before pecan planting, and applying base fertilizers to rape during deep rotary tillage; watering pecan and rape according to climate and soil moisture; and (7) cutting andcovering. Through rape interplanting, the early benefits in the pecan orchard are improved, and the incomes of growers are increased.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Chinese herbal medicine preparation for controlling dysentery of apalone ferox and preparation method thereof

InactiveCN104585548AAddress riskSolve benefitsFood processingAnimal feeding stuffPeppermintsHouttuynia

The invention discloses a Chinese herbal medicine preparation for controlling dysentery of apalone ferox and a preparation method thereof, belonging to the technical field of chelonian feed additive processing. The Chinese herbal medicine preparation is prepared from the following raw materials: orange peels, common andrographis herb, rhubarb, garlic, cassia bark, peppermint, leaves of balsam pear, baikal skullcap root, indigowoad root, Indian buead, heartleaf houttuynia herb, hyssopus officinalis, Japan clover herb, liquorice root and Chinese cinquefoil herb. The Chinese herbal medicine preparation is prepared through the steps of drying, grinding, sieving, mixing, granulating, drying, cooling, packaging, and the like. The Chinese herbal medicine preparation has the beneficial effects that the Chinese herbal medicine preparation integrates the effects of various Chinese herbal medicines and can achieve the functions of clearing heat-fire, eliminating dampness and regulating the middle warmer and removing toxicity; the apalone ferox has good preparation absorption effects, and the Chinese herbal medicine preparation takes effect quickly, has long duration and can achieve the effects of enhancing the disease resistance of the apalone ferox, effectively controlling dysentery of the apalone ferox, increasing the survival rate of the apalone ferox and reducing the risks of farmers; the Chinese herbal medicine preparation is simple in preparation method and low in production cost and is beneficial to popularization and application.

Owner:NANNING CHUNHUA AGRI TECH

Independent silver ore flotation method

InactiveCN105289850AIncrease buoyancyImprove utilization efficiencyFlotationEconomic benefitsMaterials science

The invention relates to an independent silver ore flotation method and belongs to the ore dressing technologies. The independent silver ore flotation method includes the step that lead concentrate is used as a carrier for flotation of independent silver ore, i.e., independent silver ore is ground and then placed into a flotation tank, the lead concentrate is added and stirred fully, then an adjusting agent and a collecting agent are added, and silver is effectively concentrated through flotation. By means of the independent silver ore flotation method, independent silver ore resources difficult to process currently can be effectively recycled, the silver grade and the silver recycling rate are greatly improved, and the independent silver ore flotation method has good economic benefits.

Owner:KUNMING UNIV OF SCI & TECH

Net cage culture method of young sea horses

ActiveCN105475198ASolve the costSolve the problem of small breeding capacityClimate change adaptationPisciculture and aquariaCage cultureHabit

The invention relates to the field of young sea horse culture, in particular to a net cage culture method of young sea horses. According to the net cage culture method of young sea horses, net cages of a specific specification are used, and according to the living habits of sea horses, the net cages are put in a muddy pond in a coastal mud flat to culture young sea horses. By means of the method, at the same input, the operation of manual culture of young sea horses is simple, and high-survival-rate culture of young sea horses is completed.

Owner:青岛浩然海洋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com