V-shaped bracket blanking and bending die

A blanking bending and mold technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing production time, increasing human resources, and consuming large energy, so as to achieve improved work efficiency, high economic benefits, The effect of less crafting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

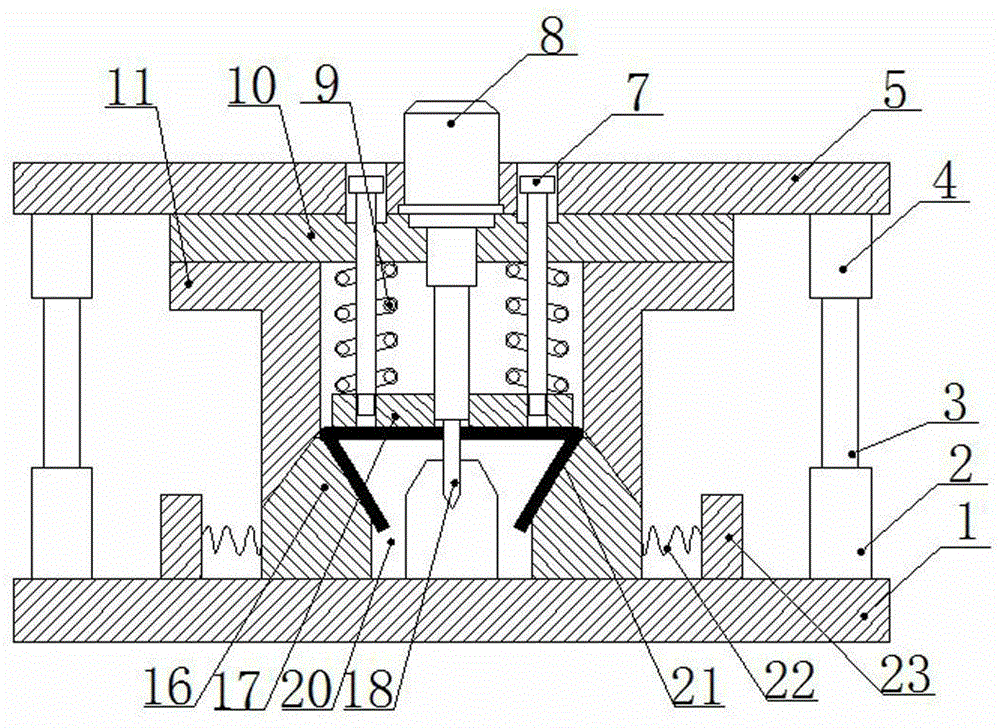

[0010] A V-shaped bracket blanking bending mold such as figure 1 As shown, it includes: upper mold base 5, fixed wedge plate 11, movable wedge plate 16, fixed block 23, spring 22, spring 12, mold handle 8, mounting plate 10, guide post 3, lower guide sleeve 2, lower mold base 1. Spring 9, pull rod 7, forming punch 20, pressure plate 17, cutting punch 18, upper guide sleeve 4 and workpiece 21. The lower end of the upper mold base 5 is provided with a mounting plate 10, a wedge plate 11 is fixed between the mounting plate 10 and the lower mold base 1, the top of the fixed wedge plate 11 contacts the bottom end of the mounting plate 10, and the bottom end of the fixed wedge plate 11 Form an inclined plane, a movable wedge 16 and a positioning block 23 are arranged between the fixed wedge 11 and the lower mold base 1, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com