Method for preparing high-grade resin by catalytic hydrogenation

A technology for catalytic hydrogenation and hydrogen preparation, applied in the field of petroleum resin hydrogenation, can solve the problems of low product grade and poor economic benefits, and achieve the effects of less softening point, lower softening point and wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

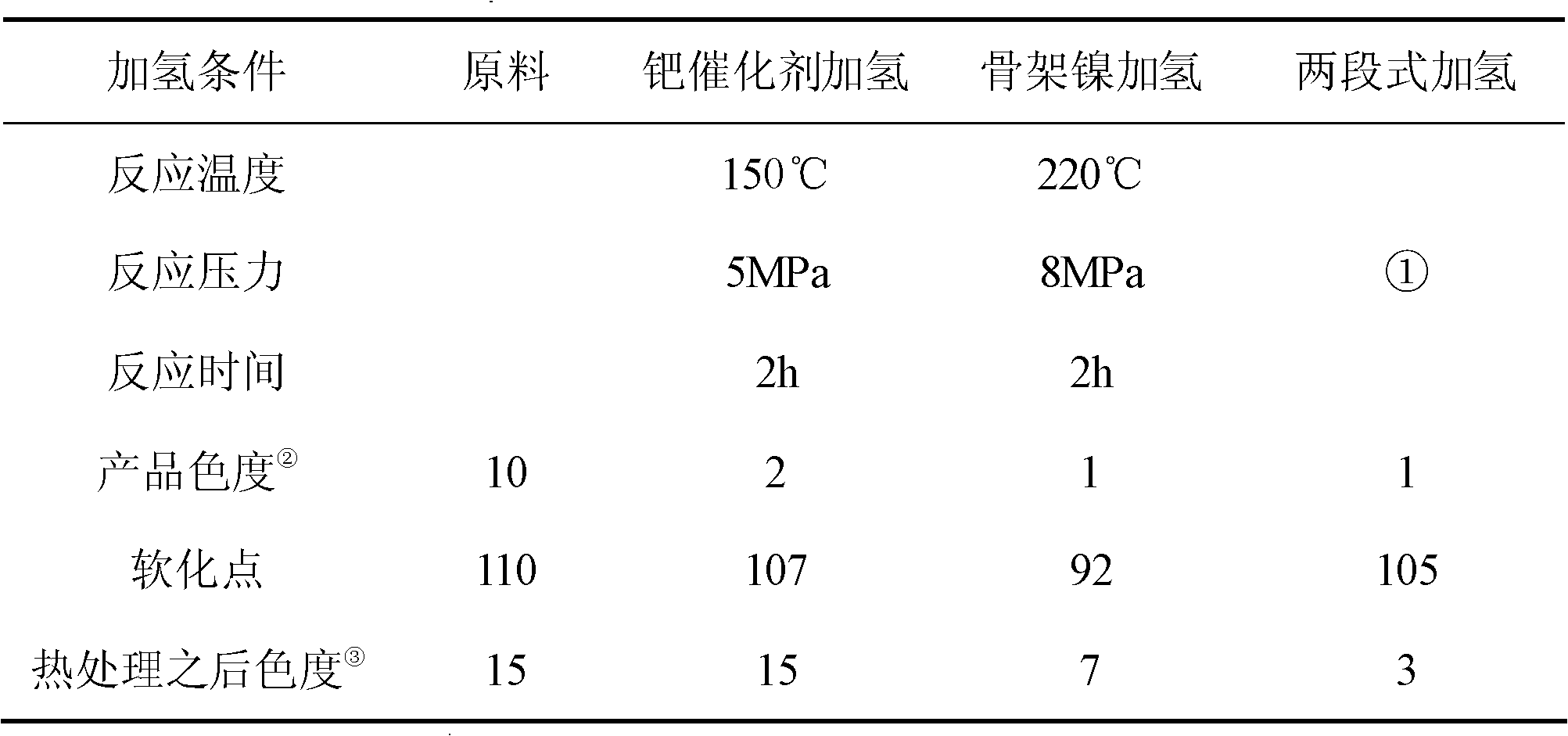

[0017] Embodiment 1: put into resin, solvent, palladium catalyst in one-stage kettle type high-pressure reactor, the ratio of solvent and resin is 10: 1, and the palladium catalyst consumption is 5wt% of resin, airtight rear replacement air is filled with 5MPa hydrogen, Slowly heated to the reaction temperature, the reaction temperature is 150 ° C, and then kept for 2h. Put the reacted reaction solution into the two-stage kettle-type high-pressure reactor and then add the skeleton nickel catalyst. The amount of nickel catalyst is 20wt% of the resin. After sealing, replace the air, fill with 8MPa hydrogen, and slowly heat to the reaction temperature. The reaction temperature is 220 ℃, and then keep for 2h. See the following table 1 for raw material properties, one-stage hydrogenation and two-stage hydrogenation results

[0018]

[0019] ① Hydrogenation was performed at 150°C over palladium catalyst for 2 hours, and then at 220°C over skeletal nickel catalyst for 2 hours.

...

Embodiment 2

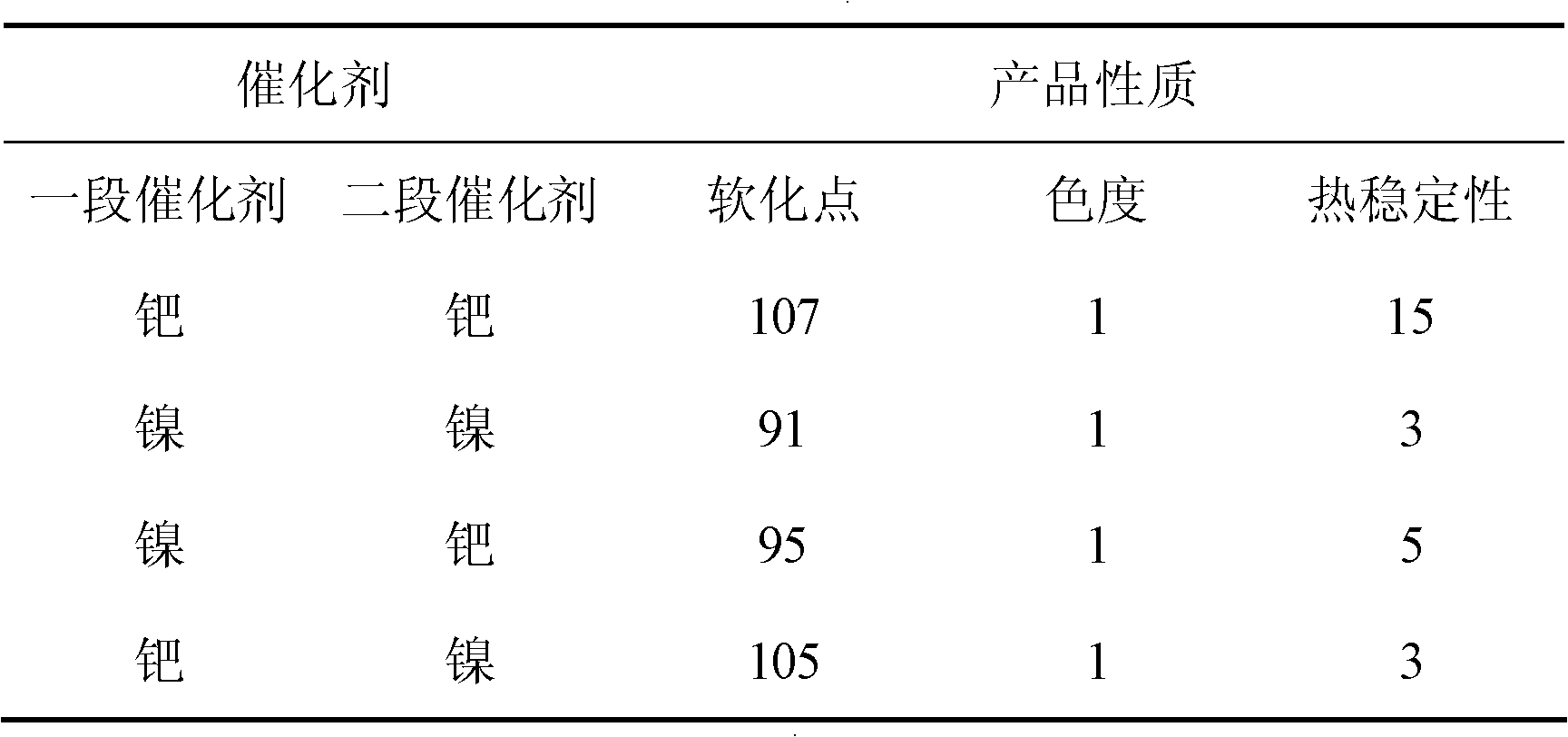

[0023] Embodiment 2: put into resin, solvent, palladium catalyst in one-stage tank type high-pressure reactor, the ratio of solvent and resin is 10: 1, and the palladium catalyst consumption is 5wt% of resin, airtight rear replacement air is filled with 5MPa hydrogen, Slowly heated to the reaction temperature, the reaction temperature is 150 ° C, and then kept for 2h. Add the reacted reaction liquid to the two-stage kettle-type high-pressure reactor and add palladium catalyst. The amount of nickel catalyst is 5wt% of the resin. After sealing, replace the air, fill with 8MPa hydrogen, and slowly heat to the reaction temperature. The reaction temperature is 220°C , and then keep for 2h. See Table 2 below for resin properties after hydrogenation.

[0024]

[0025] It can be seen from Table 2 that the hydrogenation resin was prepared by using the precious metal palladium as the first-stage hydrogenation catalyst and the second-stage hydrogenation catalyst, and the resin was hy...

Embodiment 3

[0026] Embodiment 3: Put resin, solvent, palladium catalyst in one-stage kettle type high-pressure reactor, the ratio of solvent and resin is 10: 1, and the amount of skeleton nickel catalyst is 20wt% of resin, airtight rear replacement air, fills into 5MPa hydrogen , slowly heated to the reaction temperature, the reaction temperature is 150 ° C, and then kept for 2h. Put the reacted reaction solution into the two-stage kettle-type high-pressure reactor and then add the skeleton nickel catalyst. The amount of skeleton nickel is 20wt% of the resin. After sealing, replace the air, fill with 8MPa hydrogen, and slowly heat to the reaction temperature. The reaction temperature is 220 ℃, and then keep for 2h. Table 2 sees resin properties after hydrogenation

[0027] It can be seen from Table 2 that the hydrogenation reaction of the resin was carried out by using the skeleton nickel as the one-stage hydrogenation catalyst and the two-stage hydrogenation catalyst by adopting the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com