Method for arranging in-situ leaching hole drilling filter

An arrangement method and filter technology, which are applied to earth-moving drilling, mining fluids, wellbore/well components, etc., can solve the problems of low uranium concentration, ineffective leaching of uranium metal, and long leaching period, and improve the uranium content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

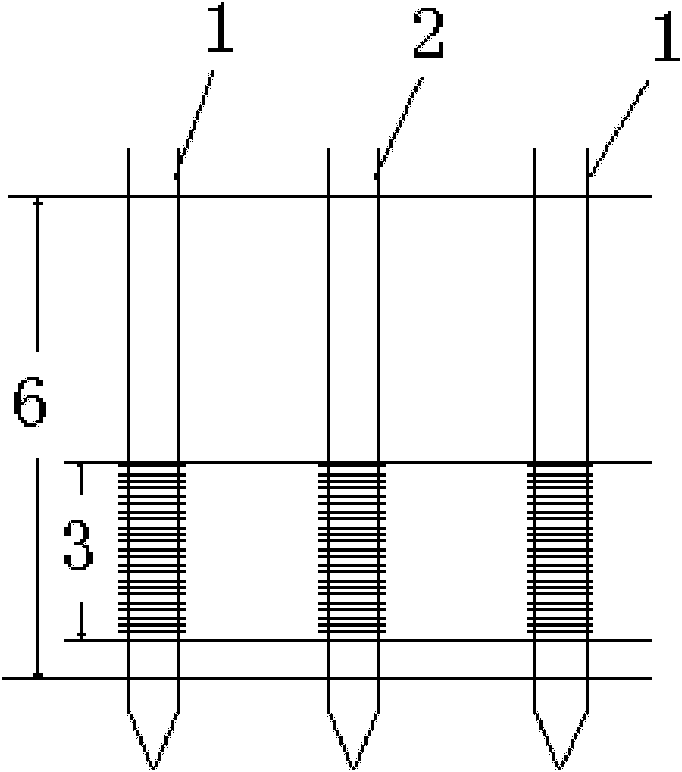

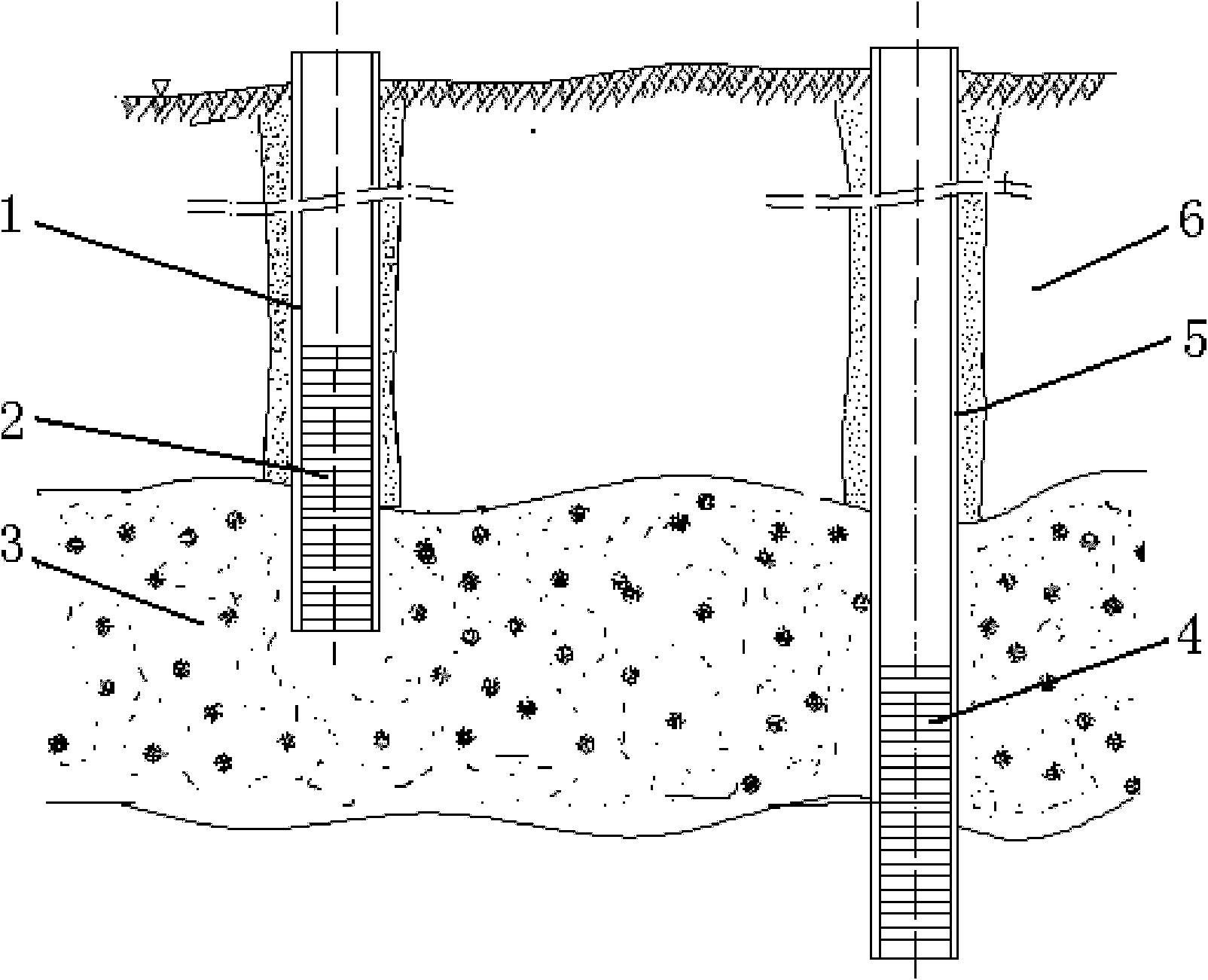

[0017] Such as figure 2 As shown, a kind of in-situ leaching borehole filter arrangement method described in the present invention is used in the production of an in-situ leaching uranium ore. When the uranium ore is a single vein, there is only one layer of uranium ore layer 3, and both the upper and lower layers of the uranium ore layer 3 are non-mineral layers 6.

[0018] There are 4 drilling holes for pumping liquid and 9 drilling holes for liquid injection. Lower the liquid pumping borehole casing 5 in the liquid pumping borehole; each of the liquid injection borehole casings 1 is provided with a liquid injection borehole filter 2, and each liquid suction borehole casing 5 is All are provided with a suction drilling filter 4.

[0019] The length of the liquid injection drilling filter 2 that is located in the liquid injection drilling casing 1 is 3 / 4 of the thickness of the uranium ore layer 3, and the bottom end of the liquid injection drilling filter 2 is positioned ...

Embodiment 2

[0025] The difference from Example 1 is:

[0026] The bottom end of the liquid injection drilling filter 2 is located at the top of the uranium ore layer 3 , and the top of the liquid injection drilling filter 2 extends upwards to the non-ore layer 6 .

[0027] The top of the liquid suction borehole filter 4 is located at the bottom of the uranium ore layer 3 , and the bottom end of the liquid suction borehole filter 4 extends downward to the non-mineral layer 6 .

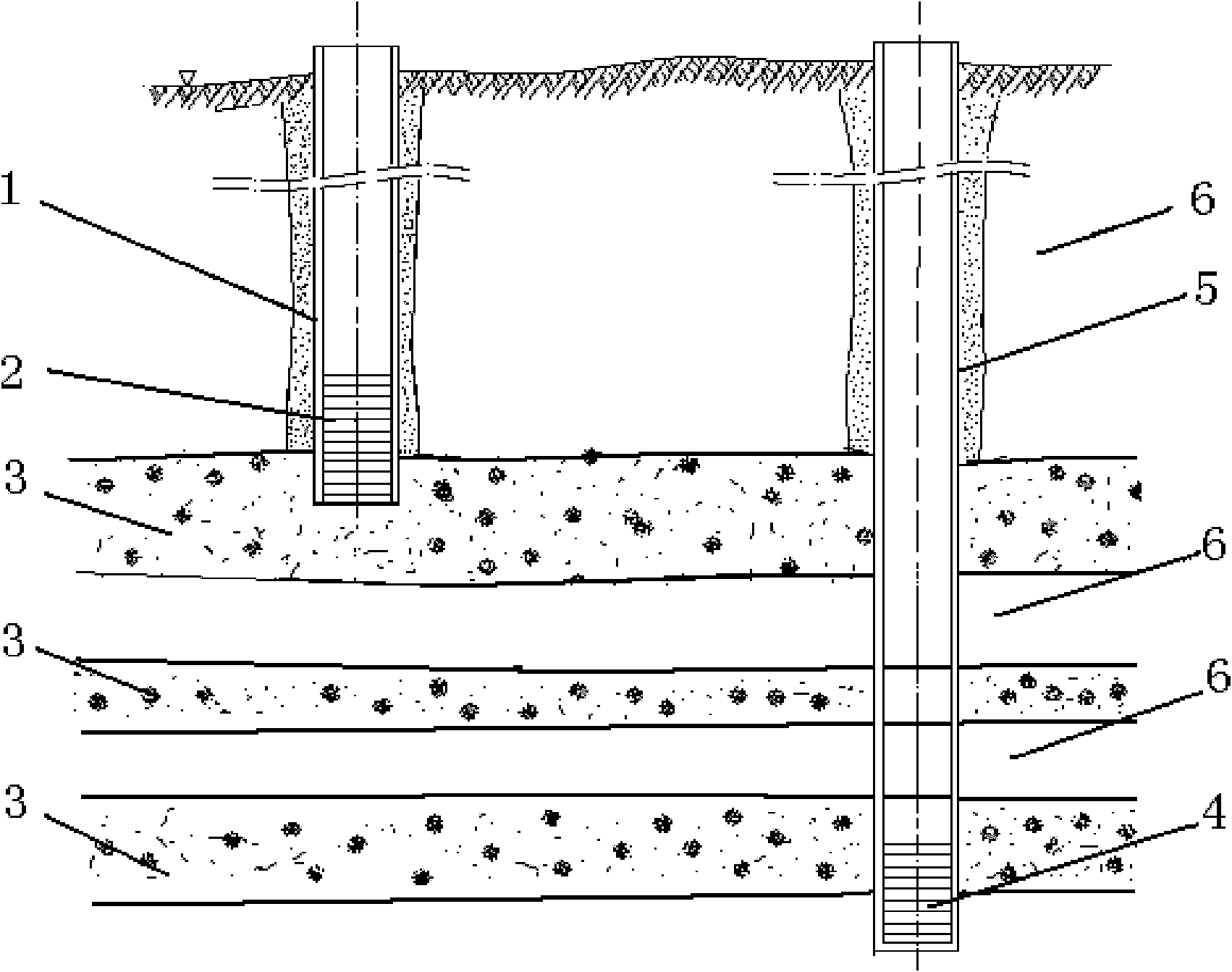

Embodiment 3

[0029] The difference from Example 1 is:

[0030] The length of the liquid injection drilling filter 2 arranged in the liquid injection drilling casing 1 is 4 / 5 of the thickness of the uranium ore layer 3, and the bottom end of the liquid injection drilling filter 2 is located at 1 / 3 of the thickness of the uranium ore layer 3 , the top of the liquid injection drilling filter 2 extends upwards to the non-mineral layer 6 .

[0031] The length of the liquid suction borehole filter 4 is 4 / 5 of the thickness of the uranium ore layer 3, the top of the liquid suction borehole filter 4 is located at 2 / 3 of the thickness of the uranium ore layer 3, and the bottom of the liquid suction borehole filter 4 The end extends down to the non-mine layer 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com