Full-ceramic fuel rod

A technology for fuel rods and ceramics, which is used in fuel elements, reactor fuel elements, surveying, mapping and navigation, etc., can solve the problems of low uranium loading, improve uranium loading, improve overall safety characteristics, improve high temperature strength and corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

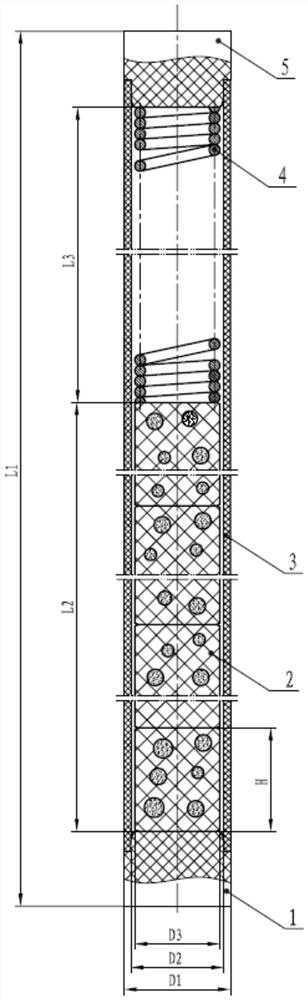

[0031] This embodiment provides an all-ceramic fuel rod with a structure such as figure 1As shown, including the cladding 3, the upper and lower ports of the cladding 3 are respectively provided with an upper end plug 5 and a lower end plug 1; a plurality of FCM core blocks 2 are stacked and installed in the lower section of the cladding 3 from bottom to top; An air cavity is set in the upper section, and an air cavity spring 4 is arranged in the air cavity. The axial top end of the air cavity spring 4 is in contact with the upper end plug 5, and the axial bottom end is in contact with the FCM core block 2. The air cavity spring 4 should have sufficient pressing force , to prevent the FCM core block 2 from being dislocated or the FCM core block 2 and the cladding shell 3 colliding with each other during transportation.

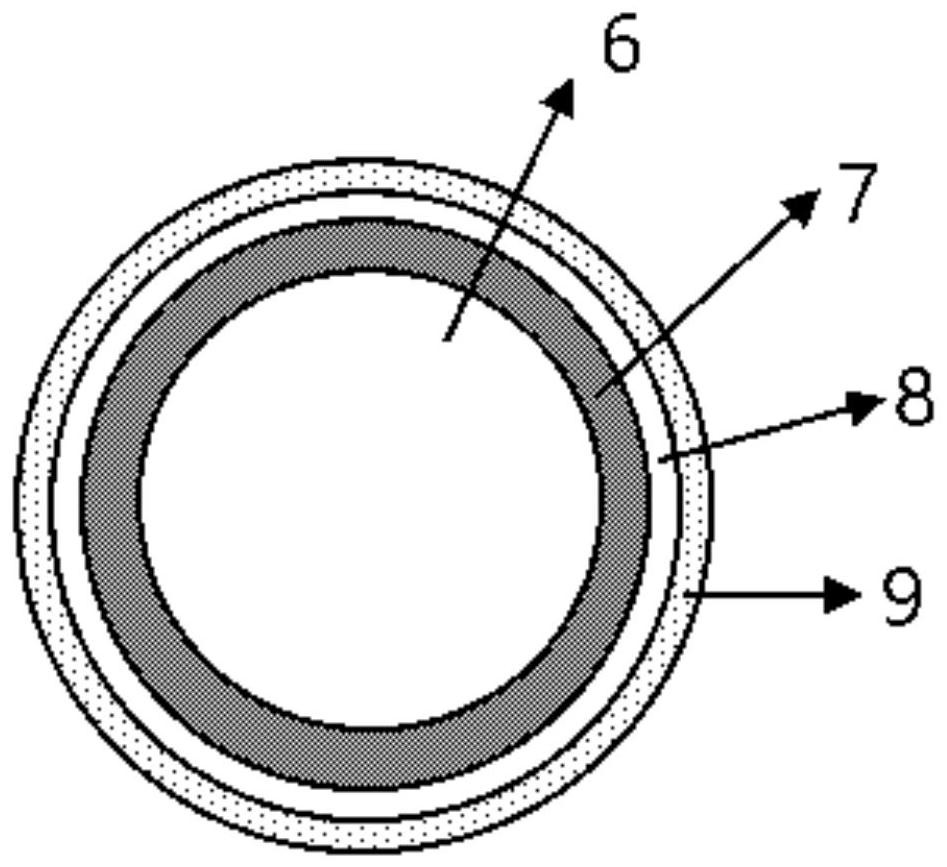

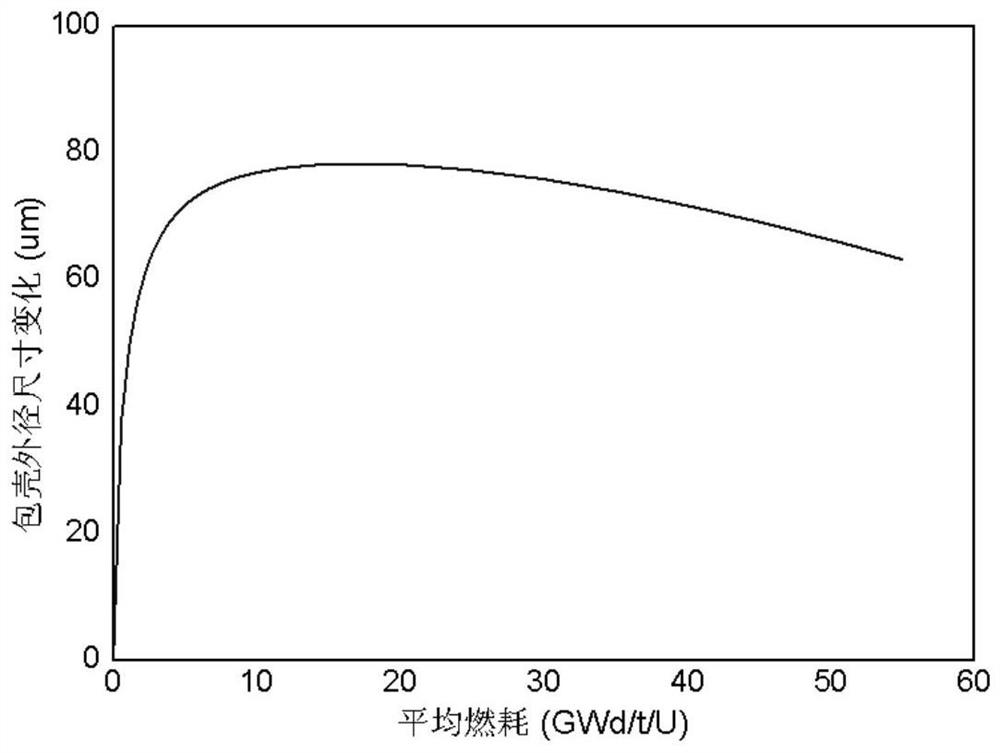

[0032] This embodiment optimizes the design of the fuel rod from three aspects: the cladding structure and parameter design, the structure and parameter desig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Free height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com