Intensified uranium ore heap leaching method

A uranium ore and enhanced heap technology, which is applied in the field of uranium ore heap leaching, can solve the problems of low leaching power, low acid concentration of leaching agent, and high slag grade, and achieve the effects of accelerating metal leaching, shortening leaching time, and reducing slag grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

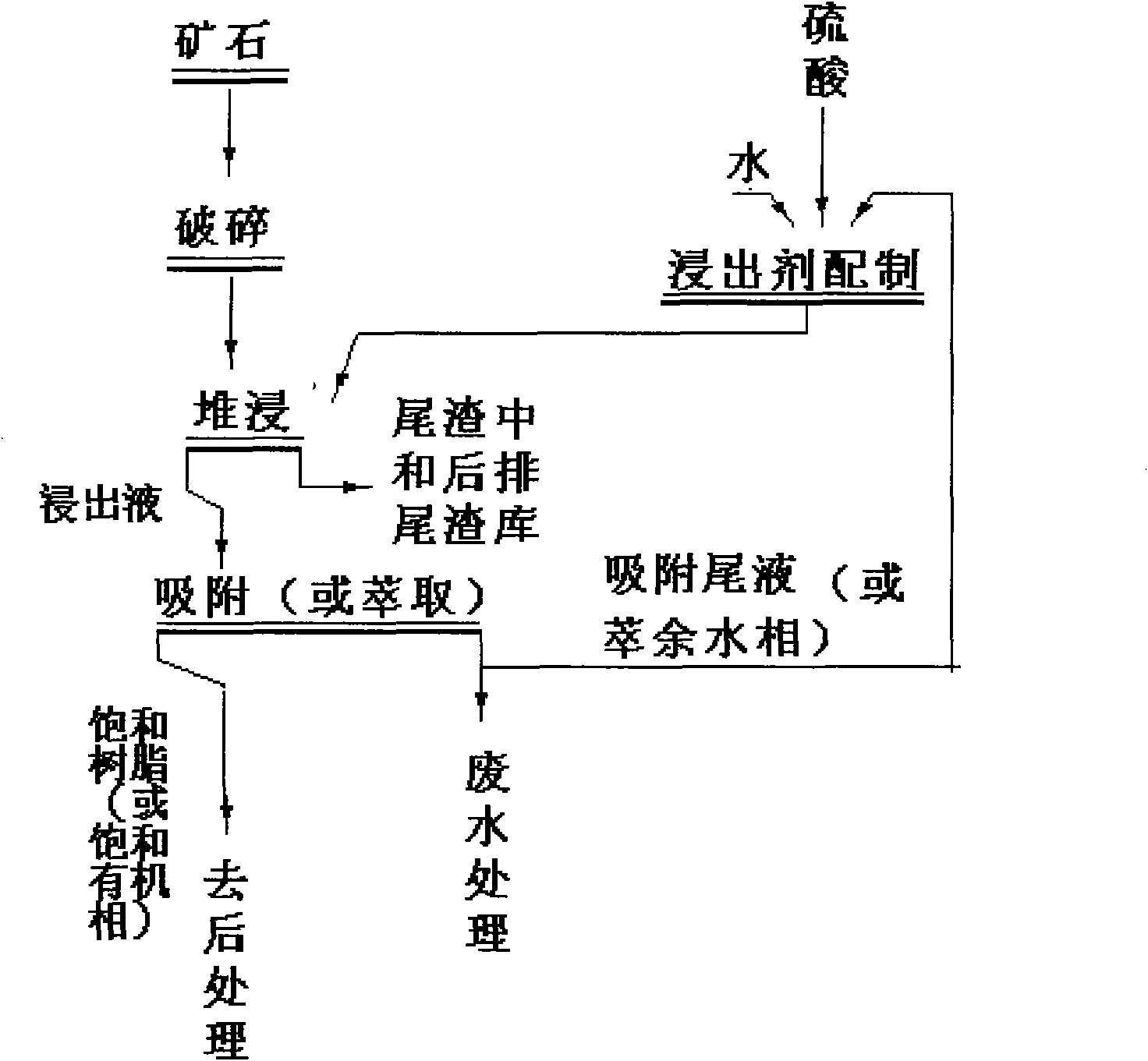

[0020] Such as figure 2 As shown, adopt the uranium ore enhanced heap leaching method described in the present invention, carry out heap leaching to the first ore of raw ore grade at 0.110%, its specific steps are as follows:

[0021] (1) First crush the uranium ore and transport it to the heap leaching site for heaping;

[0022] (2) Spray leaching agent (sulfuric acid) for ore heap leaching, use high spray intensity spray leaching agent in the initial stage, and the spray intensity is greater than 30L / m 2 h, so that the metal uranium to be leached is leached as soon as possible, and then the spraying intensity is gradually reduced. After 25 days, the leaching rate of the leached metal uranium reaches 75%, and the spraying of the leaching agent is stopped;

[0023] (3) Adsorb or extract the leaching solution obtained in step (2), and the saturated resin or saturated organic phase containing uranium metal enters the post-treatment process, and the adsorption tail liquid or ra...

Embodiment 2

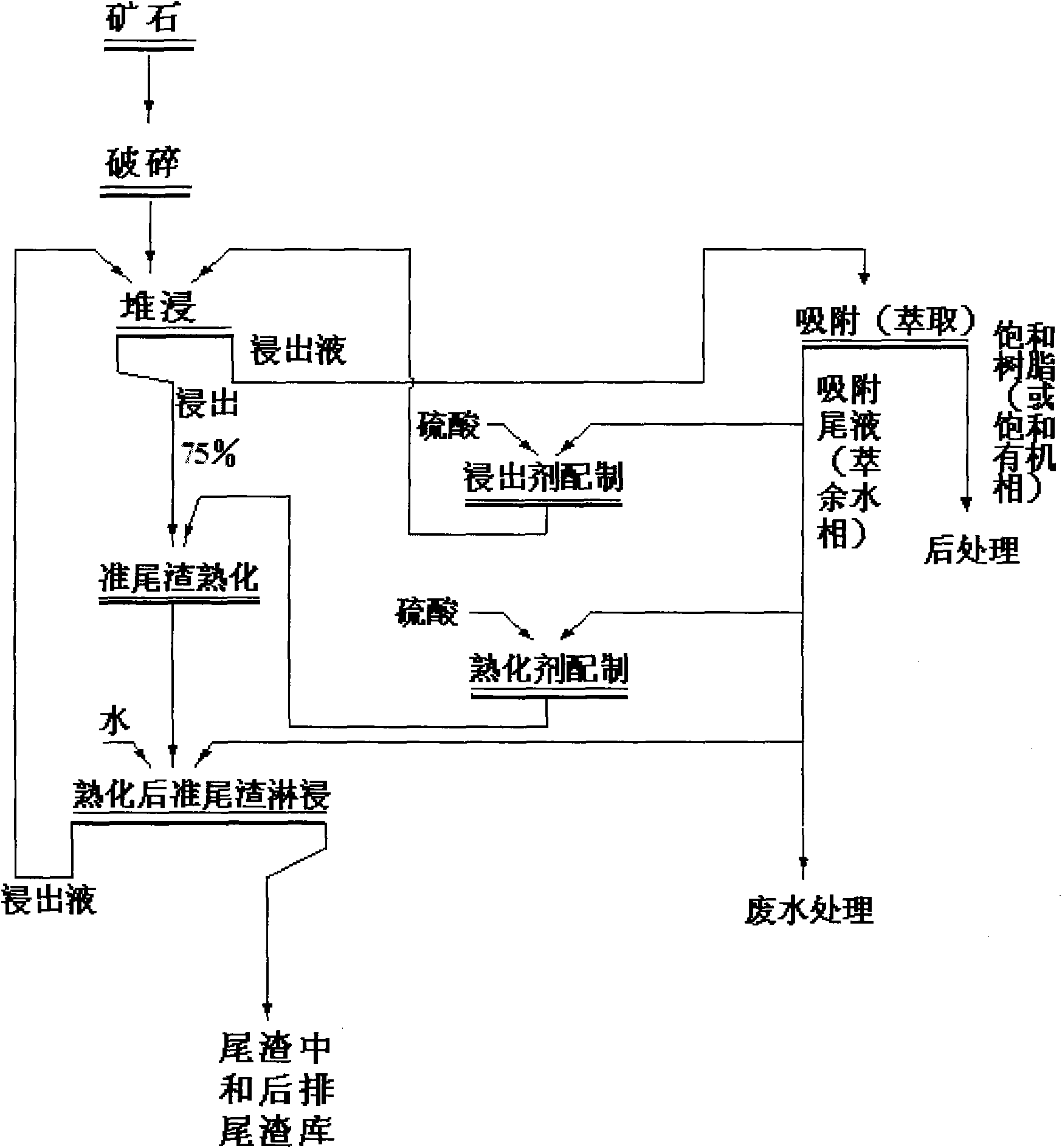

[0029] Adopt the enhanced heap leaching method of uranium ore of the present invention, carry out heap leaching to the ore grade B of 0.124% of raw ore grade, its specific steps are as follows:

[0030] (1) First crush the uranium ore and transport it to the heap leaching site for heaping;

[0031] (2) Spray leaching agent (sulfuric acid) for ore heap leaching, use high spray intensity spray leaching agent in the initial stage, and the spray intensity is greater than 30L / m 2 h, so that the metal uranium to be leached is leached as soon as possible, and the spraying intensity is gradually reduced in the future. After 30 days, the leaching rate of the metal uranium reaches 70%, and the spraying of the leaching agent is stopped;

[0032] (3) Adsorb or extract the leaching solution obtained in step (2), the saturated resin or saturated organic phase containing uranium metal enters the post-treatment process, and the adsorption tail liquid or raffinate water phase can be supplement...

Embodiment 3

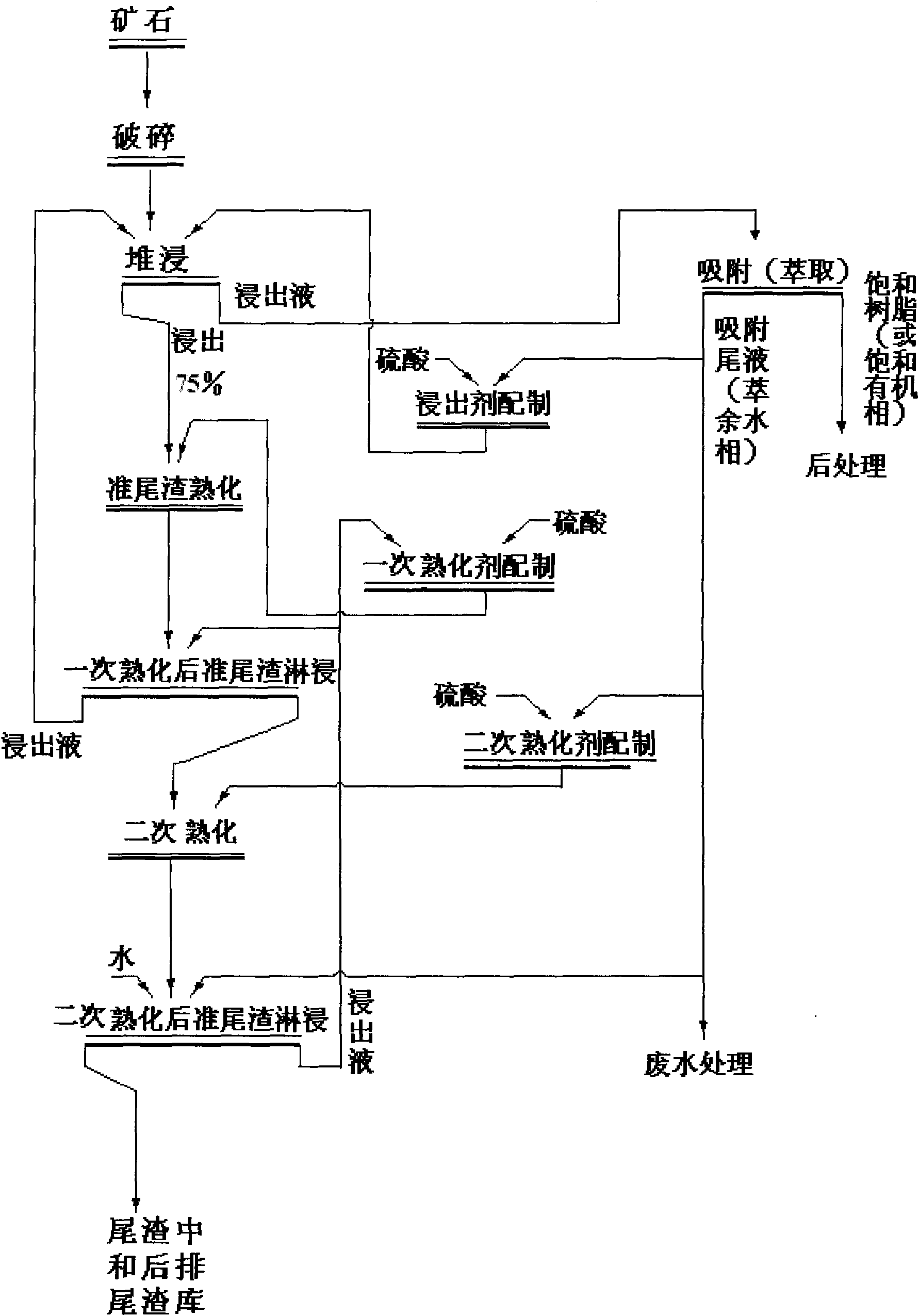

[0038] Adopt the uranium ore enhanced heap leaching method described in the present invention, carry out heap leaching to the raw ore grade at 0.196% C ore, its specific steps are as follows:

[0039] (1) First crush the uranium ore and transport it to the heap leaching site for heaping;

[0040] (2) Spray leaching agent (sulfuric acid) for ore heap leaching, use high spray intensity spray leaching agent in the initial stage, and the spray intensity is greater than 30L / m 2 h, so that the metal uranium to be leached is leached as soon as possible, and then the spraying intensity is gradually reduced. After 55 days, the leaching rate of the leached metal uranium reaches 80%, and the spraying of the leaching agent is stopped;

[0041] (3) Adsorb or extract the leaching solution obtained in step (2), the saturated resin or saturated organic phase containing uranium metal enters the post-treatment process, and the adsorption tail liquid or raffinate water phase can be supplemented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com