Fluoride-resistant ore leaching bacterium and application thereof in efficient leaching process of high-fluoride uranium ore

A technology of ore leaching bacteria and fluorine resistance, which is applied in the field of fluorine-resistant ore leaching bacteria and biological leaching technology, can solve the problems of difficult control of environmental pollution, serious equipment loss, and inability to continue to use, etc., achieve short leaching time, increase recovery rate, and strong The effect of fluorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

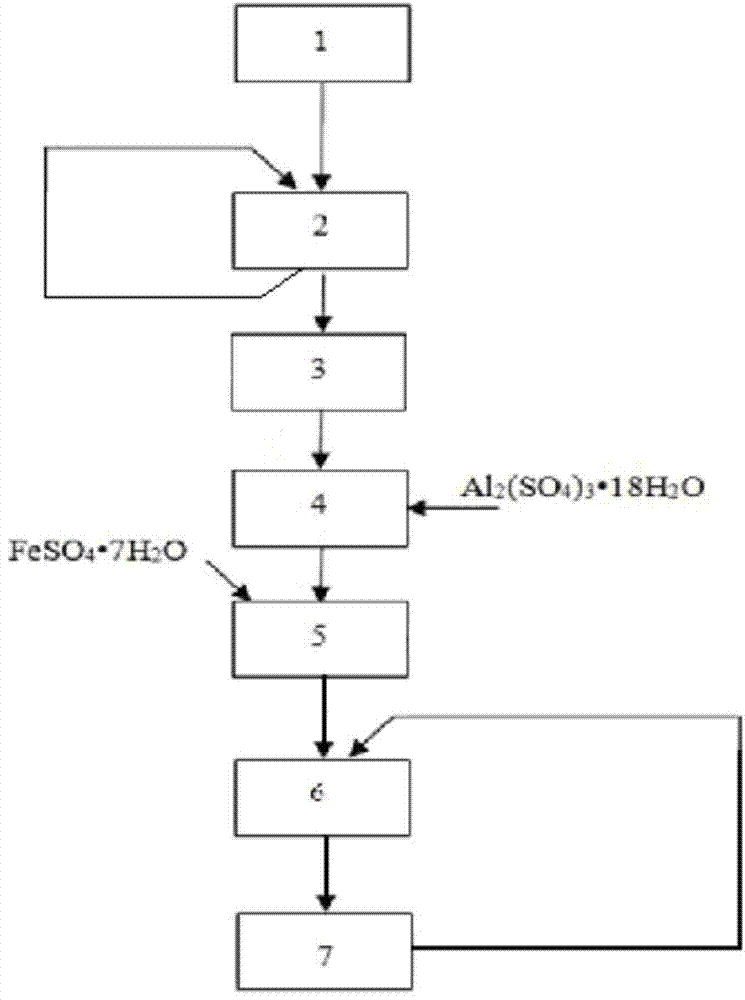

[0026] The fluorine-resistant ore leaching bacteria provided by the invention is applied to a high-efficiency leaching process suitable for high-fluorine uranium ore. The specific implementation is as follows:

[0027] (1) Fluoride-resistant leaching bacteria

[0028] The fluorine-resistant ore leaching strain Acidithiobacillus ferrooxidans used in the present invention is isolated from ores freshly taken from the high-fluoride uranium mining area, and preserved in the General Microorganism Center of the China Microbiological Culture Collection Management Committee (CGMCC for short), and the preservation date: July 2013 On January 1, the deposit number is CGMCC NO.7836.

[0029] (2) After the ore mined from the mine is crushed to a particle size of <40mm, it is piled up and heap leached with a height of 3m to 6m, and the high fluorine uranium ore is acidified and pretreated with dilute sulfuric acid with a pH of 1.0 to 2.0;

[0030] (3) The acidification solution obtained fr...

Embodiment 1

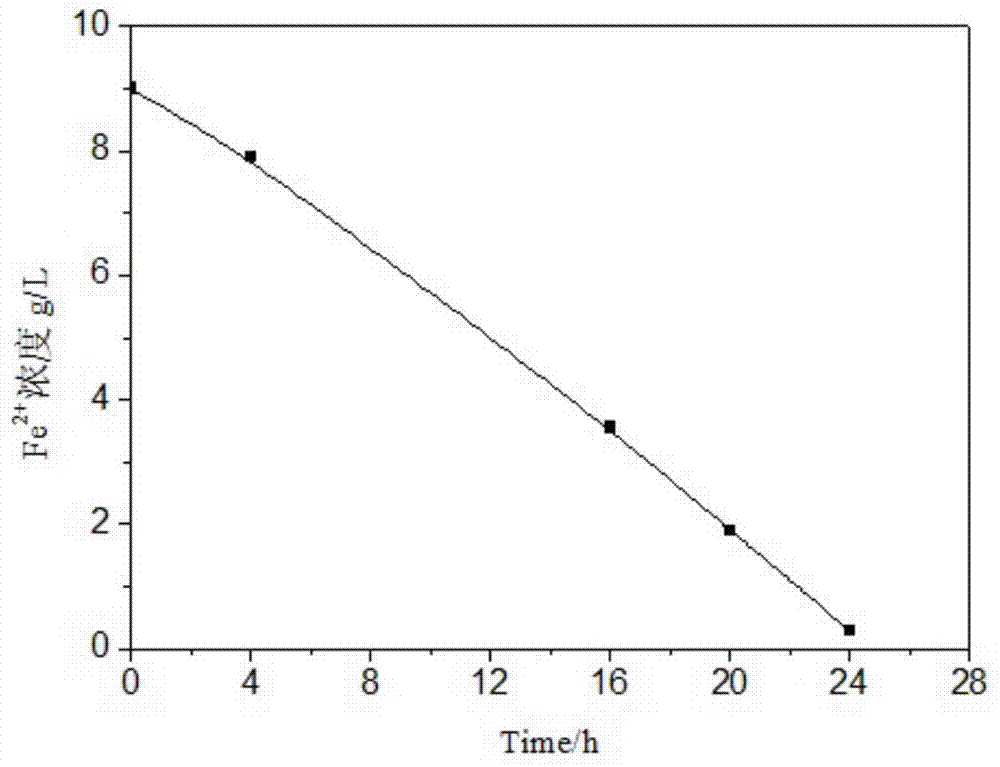

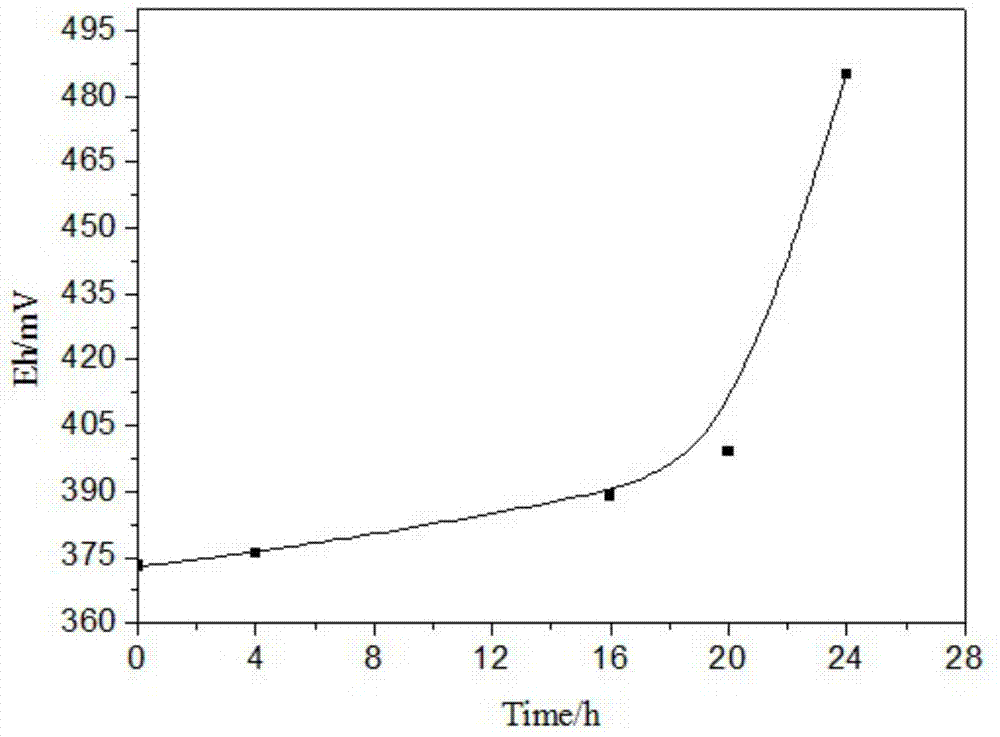

[0037] Example 1 Application of fluorine-resistant leaching bacteria to leaching a certain high-fluoride uranium ore in Guangdong

[0038] (1) Ore properties

[0039] A high fluorine uranium mine located in Shaoguan, Guangdong, the main uranium-containing minerals are pitchblende, uranite, titanium uranite, uranium thorium, etc., the average content of U is 0.20%, uranium mainly exists in the form of reduction, and U in the ore 4+ It accounts for 68.9% of the total uranium. The associated metal minerals are mainly pyrite, hematite, galena, sphalerite, etc., accounting for less than 5.0% of the total, and the average content of pyrite in the ore is 0.45%; non-metallic minerals account for more than 90.0% of the total , mainly quartz, fluorite, followed by calcite, dolomite, chlorite, hydromica, potassium (sodium) feldspar, apatite, etc. The average content of F in the ore is 2.15%, and the fluorine content is relatively high.

[0040] In the high fluoride uranium ore, fluorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com