Diluted acid in-situ leaching uranium mining technology

A technology for in-situ leaching of uranium and technology, which is applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc., and can solve the problems of low leaching efficiency, insufficient oxygen injection, and low production volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

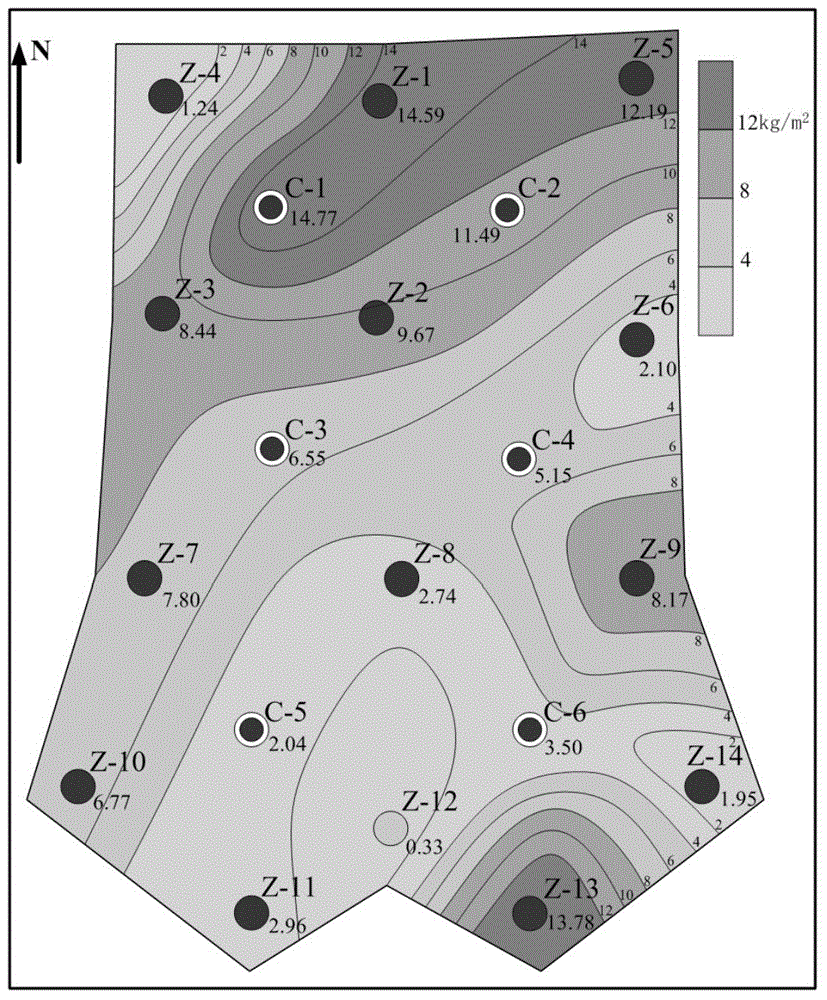

[0025] The average thickness of the ore body in the Nalinggou uranium deposit test area is 4.40m, the average grade is 0.0709%, and the average square meter uranium content is 6.38kg / m 2 , with an average buried depth of 400m. Average carbonate content in CO 2 That works out to be 3.41%.

[0026] Test blocks such as figure 1 As shown, dilute hydrochloric acid + oxygen leaching process is adopted, and the operation steps are detailed as follows:

[0027] Step 1, 20 days of circulating injection without adding reagents;

[0028] Step 2, on the 20th day, the temperature of the liquid injection system is 16° C., the pressure is 1 MPa, and 400 mg / l of oxygen is added. Concentrated hydrochloric acid was added online to keep the pH value of the solution at 3-4.

[0029] Step 3, Day 30, Leachate HCO 3 - When the concentration reaches 1g / l, the injection volume remains stable. Adjust the injection volume of concentrated hydrochloric acid to gradually increase the pH value of the...

Embodiment 2

[0035] Core samples collected from the Shashagetai uranium deposit, the ore sample is 0.0258%, CO 2 The content is 3.45%. Indoor dilute acid column leaching experiment, column length 113cm, column diameter 3.3cm, pore volume 340ml, porosity 35.2%, column bulk density 1.75g / cm 3 , true density 2.70g / cm 3 .

[0036] The experiment adopts the dilute hydrochloric acid + oxygen leaching process, the initial pH value of the injection solution is 3-4, and after 20 pore volumes, the permeability is 12 times higher than the initial permeability; after that, the pH value of the injection solution is adjusted to 4-5, and the pore volume is 15 Post-volume permeability increased 8-fold over initial permeability, HCO 3 - The concentration reaches 1g / l; then adjust the pH value of the injection solution to 5-6 until the leaching ends, 70 pore volumes are leached, and the uranium leaching rate reaches 64.85%.

Embodiment 3

[0038] The average thickness of the uranium deposit ore body is 4.82m, the average grade is 0.0875%, and the average uranium content per square meter is 9.02kg / m 2 , with an average buried depth of 180m. The well type adopts the five-point type, and the distance between the injection well and the extraction well is 15m.

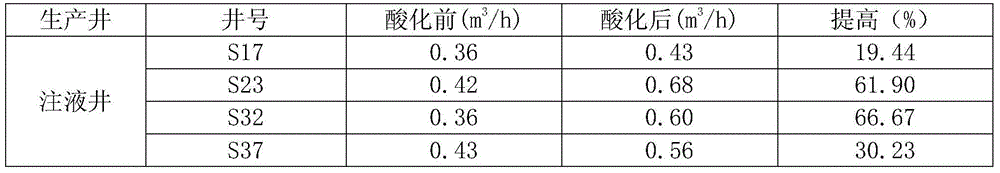

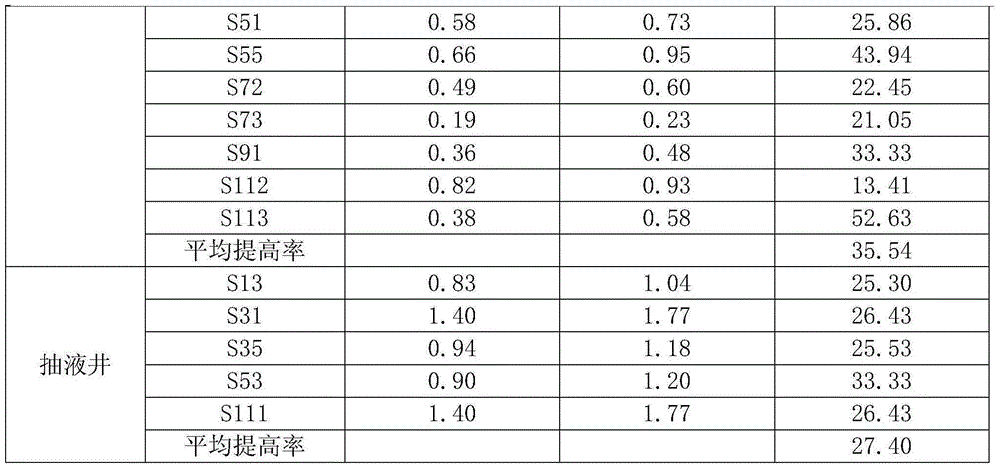

[0039] The dilute hydrochloric acid + oxygen leaching process is adopted, and the pH value of the initial injection solution is 4-5. After 2 months, the leaching solution HCO 3 - The concentration increased from 250mg / l at the background to more than 1500mg / l; 5 extractions, 11 injections and 16 production wells dilute hydrochloric acid acidification leaching were all effective, and the maximum injection rate of the injection wells increased by 66.67%, with an average increase of 35.54%. Increased by 33.33%, with an average increase of 27.40% (Table 1).

[0040] Table 1 Changes of injection volume before and after dilute acid acidification in Shashagetai ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com