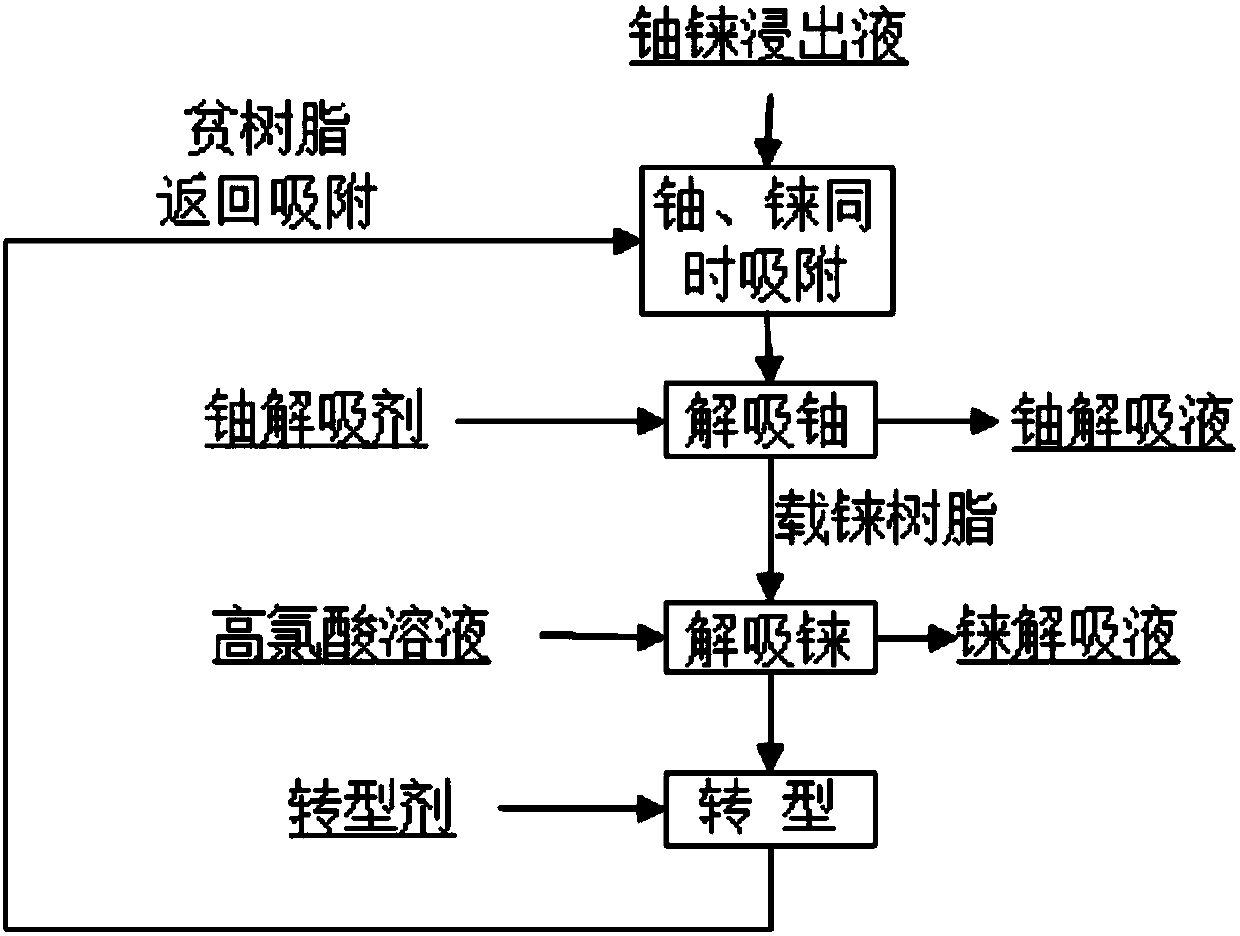

Method for comprehensively recovering uranium and rhenium from leaching solution with ion exchange resin

A technology of ion exchange resin and leaching solution, which is applied in the field of uranium-rhenium resources development in hydrometallurgy, can solve the problems of low rhenium concentration, difficulty in separation and recovery, and high mass concentration ratio, and achieve low cost, simple process, and high-efficiency recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The composition of the leachate is shown in Table 1.

[0082] Table 1 Test results of acidic uranium and rhenium leachate components 1

[0083] Element

U

Re

ΣFe

Fe 3+

SO 4 2-

residual acid

ρ B / (g·L -1 )

0.172

0.003

2.54

0.87

15.3

8.7

[0084] 1) Simultaneous adsorption of uranium and rhenium. The resin is ZGA352 resin, the inner diameter of the resin column is 6 mm, and the height of the resin bed is 750 mm. The adsorption contact time is 5 minutes, and the penetration point of uranium is controlled to be 2.0mg / L. It penetrates when adsorbed at 150BV, and reaches saturation when adsorbed at 300BV. The saturated capacity of uranium is 33mg / mL (wet resin), and the adsorption rate of uranium is 99%. Liquid rhenium concentration < 0.1mg / L, rhenium adsorption rate above 97%, loading resin rhenium capacity 0.9mg / mL (wet resin).

[0085] 2) Desorption of uranium. The desorption agent is 5g / L sulfuric ...

Embodiment 2

[0089] The composition of the leachate is shown in Table 2.

[0090] Table 2 Test results of acidic uranium and rhenium leachate components 2

[0091] Element

U

Re

ΣFe

Fe 3+

SO 4 2-

residual acid

ρ B / (g·L -1 )

0.332

0.007

6.31

1.42

30.2

17.6

[0092] 1) Simultaneous adsorption of uranium and rhenium. The resin is D380 resin, the inner diameter of the resin column is 6mm, and the height of the resin bed is 750mm. The adsorption contact time is 5min, and the penetration point of uranium is controlled to be 5.0mg / L. It penetrates when adsorbing 100BV, and reaches saturation when adsorbing 200BV. The saturated capacity of uranium is 43mg / mL (wet resin), and the uranium adsorption rate is 99%. Liquid rhenium concentration < 0.1mg / L, rhenium adsorption rate 98%, loading resin rhenium capacity 1.3mg / mL (wet resin).

[0093] 2) Desorption of uranium. The desorption agent is 5g / L sulfuric acid + 50g / L sodium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com