A process for extracting uranium by ion exchange method with water closed loop

An ion-exchange, closed-loop technology

Active Publication Date: 2012-07-04

BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Outstanding ability requirements, relatively large economic investment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

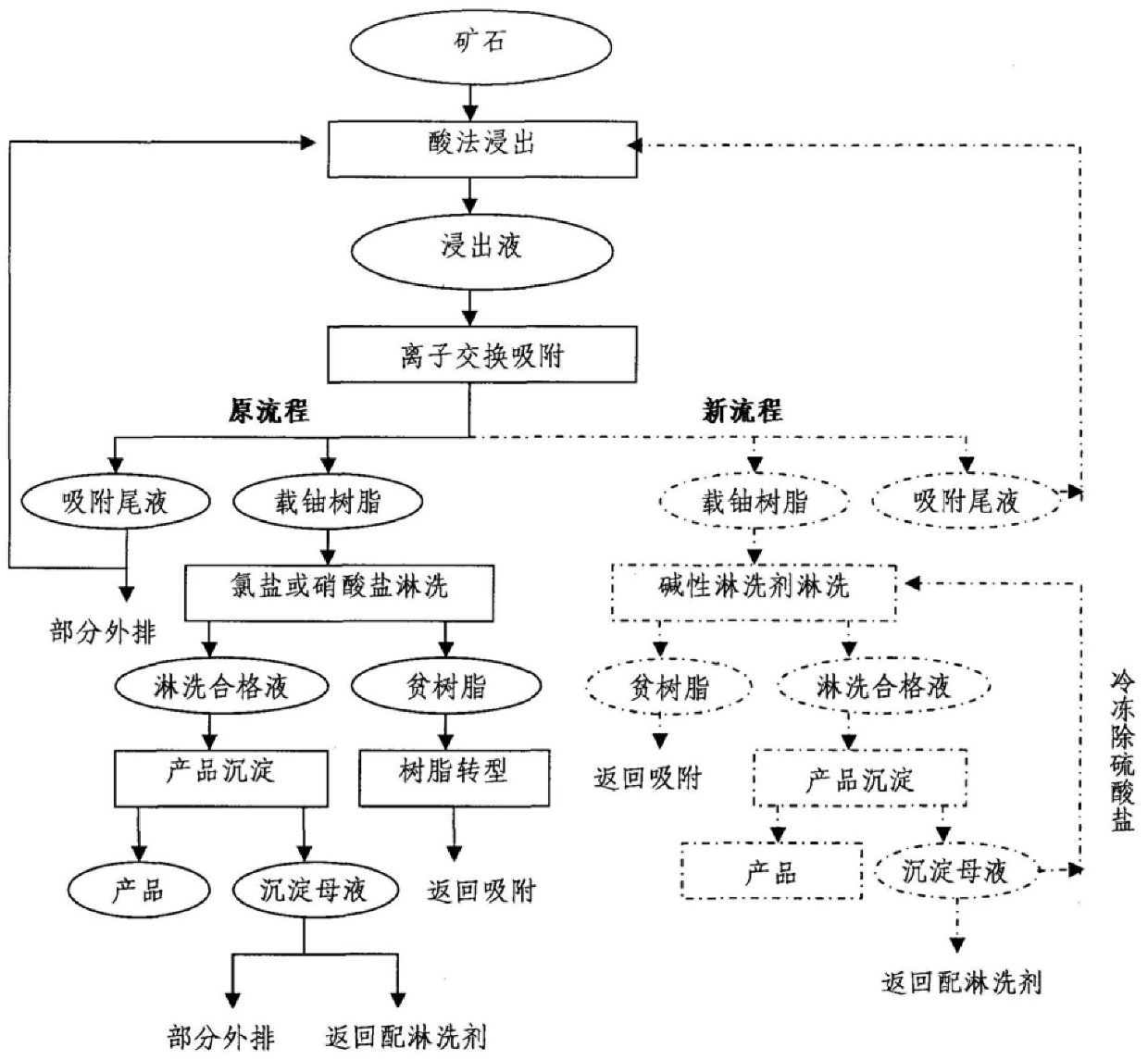

The invention provides a process for extracting uranium by the ion exchange method of water closed-circuit circulation, which first uses an acidic leaching agent to leach uranium ore; then uses a weakly basic anion exchange resin to perform ion exchange adsorption on the leaching solution to obtain a uranium-loaded resin and an adsorption tail liquid; leaching the loaded uranium resin, and recovering uranium products from the leaching liquid. It processes the loaded uranium resin according to the following steps: (1) wash the loaded uranium resin with an alkaline solution with a total carbonate or bicarbonate concentration of 0.5-1.5 mol / L; (2) wash the loaded uranium resin The resulting qualified uranium-containing eluting liquid is precipitated with NaOH; all the precipitated mother liquid is cooled by a refrigerator to remove sulfate and then returned to prepare eluent. The invention improves the traditional ion exchange uranium extraction process, that is, does not introduce chloride radicals or nitrate radicals in the leaching process of the uranium-loaded anion exchange resin, avoids adverse effects on the process flow, and realizes closed circuit circulation of process water at the same time, thereby achieving environmental protection requirements.

Description

Technical field The present invention relates to process water closed-circuit circulation technology, be specifically related to a kind of ion exchange method of water closed-circuit circulation Uranium process. Background technique Most of my country's uranium water smelters adopt acid leaching——anion exchange resin adsorption—acid chloride salt or acid Nitrate leaching-precipitation process. Adopt anion exchange method to extract uranium from acid leach solution, saturated resin generally adopts 1mol / L sulfuric acid solution Or acid chloride salt or acid nitrate as eluent for desorption. When desorbing due to adopting acid chlorate or acid nitrate, although leaching efficiency is high, desorption volume is little, but meeting Chloride or nitrate is introduced throughout the process and accumulates during the process cycle, affecting subsequent ions The adsorption of the exchange resin leads to the partial discharge of the adsorption tail liquid, which cannot ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B60/02C22B3/42

Inventor 李伟才周根茂刘超邓舜勤

Owner BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com