Pretreatment method for mud uranium ores

A uranium ore and pretreatment technology, applied in the field of uranium mining and metallurgy, can solve the problems of increasing reagent consumption and achieve the effects of saving reagent consumption, increasing leaching rate, and reducing reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

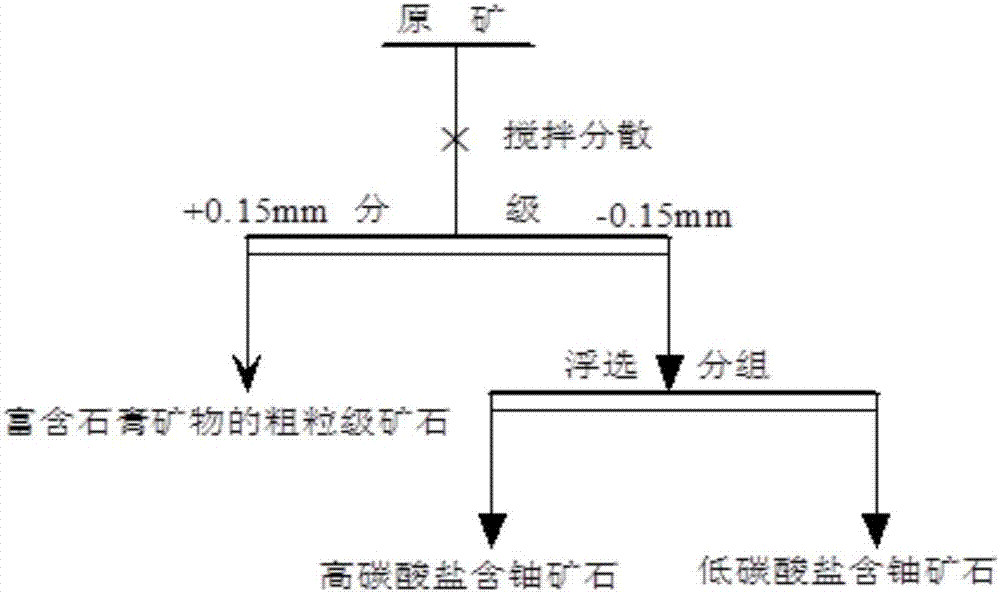

Image

Examples

Embodiment 1

[0036] A certain argillaceous uranium ore rich in gypsum and carbonate minerals, gypsum grade 13.50%, CO 2 The grade is 9.35%, and the uranium grade is 0.075%.

[0037] (1) Mix the ore and water at a ratio of 1:3, stir with an electric mixer at a stirring speed of 300r / min for 60 minutes to disperse, and use a 150-mesh sieve to divide it into two grades: +150 mesh coarse-grained ore and -150-mesh fine-grained ore . The yield rate of +150 mesh coarse-grained ore was 23.50%, the grade of gypsum was 47.39%, and the recovery rate was 82.5%; CO 2 The grade is 3.06%, and the recovery rate is 7.71%. The yield of -150 mesh coarse-grained ore is 76.50%, the grade of gypsum is 3.09%, and the recovery rate is 17.50%; CO 2 The grade is 11.28%, and the recovery rate is 92.29%.

[0038] (2) Mix -150 mesh fine-grained ore into a slurry with a concentration of 30%, put it into a flotation tank, and adjust the temperature of the slurry to 30°C. Add water glass 4000g / t to suppress and disp...

Embodiment 2

[0040] A certain argillaceous uranium ore rich in gypsum and carbonate minerals, gypsum grade 13.85%, CO 2 The grade is 9.73%, and the uranium grade is 0.072%.

[0041] (1) Mix the ore and water according to the ratio of 1:2, stir with an electric mixer at a stirring speed of 600r / min for 20 minutes to disperse, and use a 100-mesh sieve to divide it into two grades: +100 mesh coarse-grained ore and -100-mesh fine-grained ore . The yield of +100 mesh coarse-grained ore was 19.60%, the grade of gypsum was 56.39%, and the recovery rate was 79.80%; CO 2 The grade is 2.46%, and the recovery rate is 4.97%. The yield of -150 mesh coarse-grained ore is 80.40%, the grade of gypsum is 3.48%, and the recovery rate is 20.20%; CO 2 The grade is 11.50%, and the recovery rate is 95.03%.

[0042] (2) Make -100 mesh fine-grained ore into slurry with a concentration of 30%, and put it into a flotation tank, and the temperature of the slurry is 35°C. The flotation operation adopts a closed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com