Method for recycling uranium from uranium extraction tailings

A technology for recovering uranium and tailings, applied in the field of metallurgy, can solve the problems of low recovery rate of uranium, no extraction value and high extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

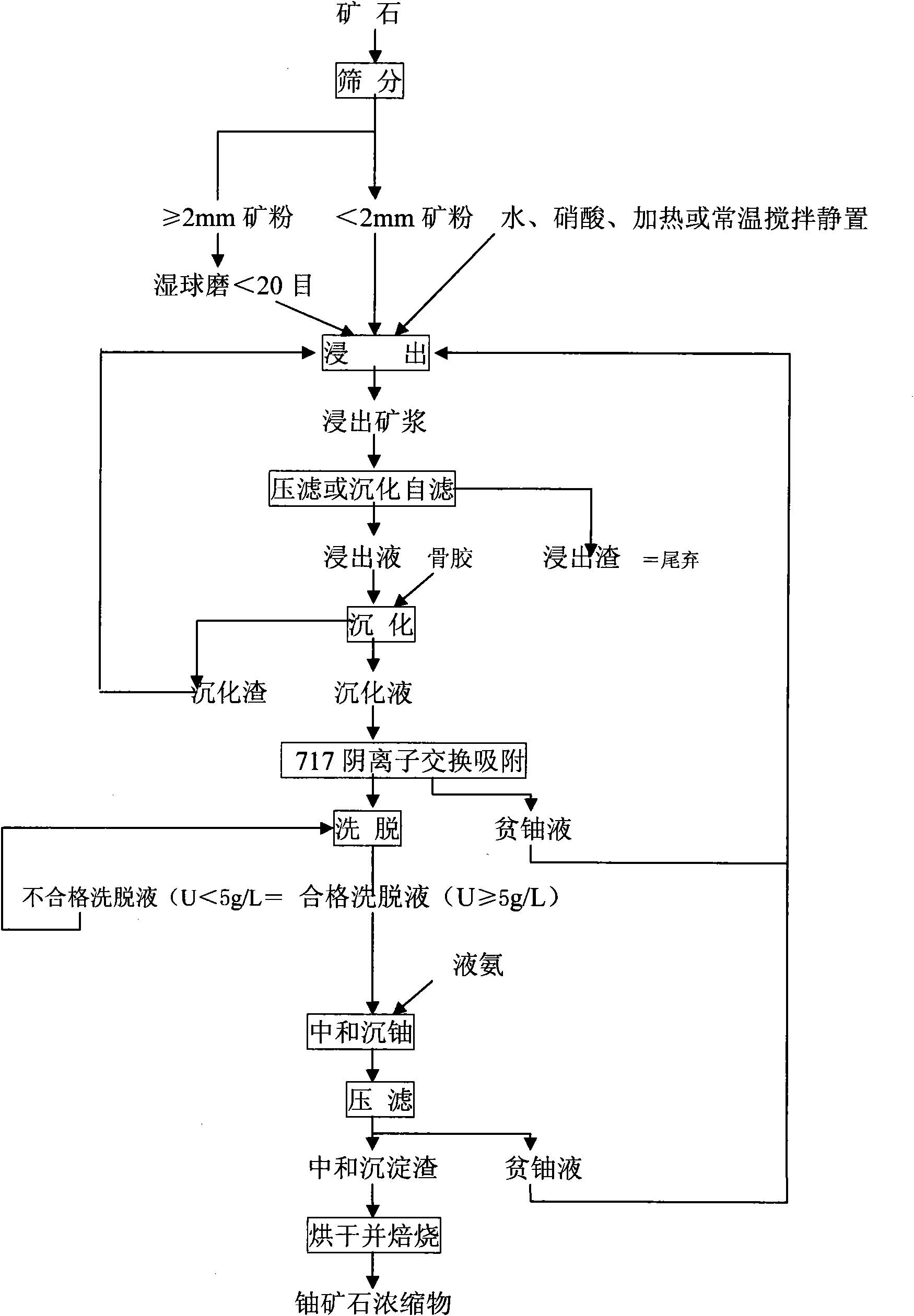

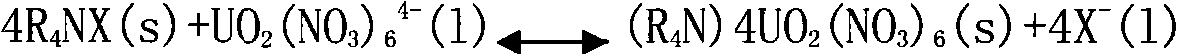

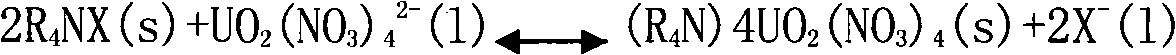

Method used

Image

Examples

Embodiment 1

[0064] Take 100g of uranium tailings, first use the screening method to separate the uranium tailings with a particle size greater than 2mm from the uranium tailings with a particle size of less than 2mm, and for the tailings particles with a particle size of more than 2mm, carry out wet grinding and crushing to below 2mm, and then combine them with the uranium tailings with a particle size of less than 2mm Mix the uranium tailings, add nitric acid and water to adjust the slurry, so that the pH value of the slurry reaches 0.6-0.9, and the volume of the nitric acid and water is controlled to be 1.5 times the tailings mass, that is, 150mL. Heat to 65-70°C for stirring and leaching for 1 hour, or stir and mix at room temperature and soak for 30 days, then separate liquid from solid, and wash the leaching residue with water twice to make the pH value of the leaching residue nearly neutral (pH=5 -7). Discard the leaching residue, add 0.01g bone glue to the nitric acid leaching solu...

Embodiment 2

[0066] Take 100g of uranium tailings, first use the screening method to separate the uranium tailings with a particle size greater than 2mm from the uranium tailings with a particle size of less than 2mm, and for the tailings particles with a particle size of more than 2mm, carry out wet grinding and crushing to below 2mm, and then combine them with the uranium tailings with a particle size of less than 2mm Mix the uranium tailings, add nitric acid and water to adjust the slurry, so that the pH value of the slurry reaches 0.6-0.9, and the volume of adding nitric acid and water is controlled to be twice the mass of the tailings, that is, 200mL. Heat to 65-70°C for stirring and leaching for 1.5 hours, or stir and mix at room temperature and soak for 30 days, then separate liquid from solid, and wash the leaching residue twice with water to make the pH value of the leaching residue nearly neutral (pH=5 -7). Discard the leaching slag, add 0.05g bone glue to the nitric acid leachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com