Method for recycling value metal from lithium cell slag containing Co, Ni, Mn

A valuable metal, lithium battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problem of high recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Leaching and solvent extraction were performed on 100 g of a paste (Co 11%, Ni 11%, Mn 11%, and Li 4.3% hereinafter simply referred to as "paste") containing a ternary metal Li salt. In the test described below, the extraction time was 10 minutes of stirring, the back extraction time was 10 minutes of stirring, and the cleaning was 10 minutes of stirring.

[0078] (1) Leaching

[0079] The paste was poured into 1000 L of a 300 g / l sulfuric acid aqueous solution, stirred while heating at 70 to 80° C. for 4 hours, and then filtered to leave 10 g of residue in a dried state. The metal concentration in the filtrate of 1000L is as follows, which can be leached 100%.

[0080] 【table 3】

[0081] filtrate co Ni mn LI Concentration (g / l) 11 11 11 4.3 Distribution rate (%) 100 100 100 100

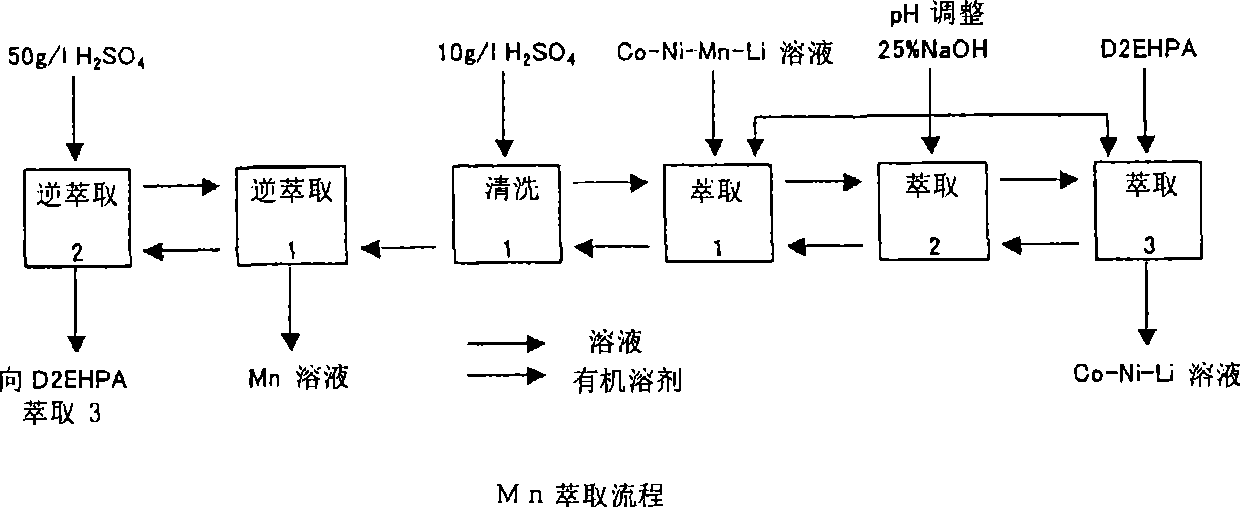

[0082] (2) Mn extraction

[0083] After the filtrate was neutralized with 25% NaOH solution, solvent extraction of Mn was performed. The neutralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com