Treatment method for high-concentration arsenic waste water

A treatment method and high-concentration technology, applied in flotation water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of harsh working environment, high operating costs, and low degree of automation of treatment processes, etc. problem, to achieve the effect of reducing the amount of arsenic slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

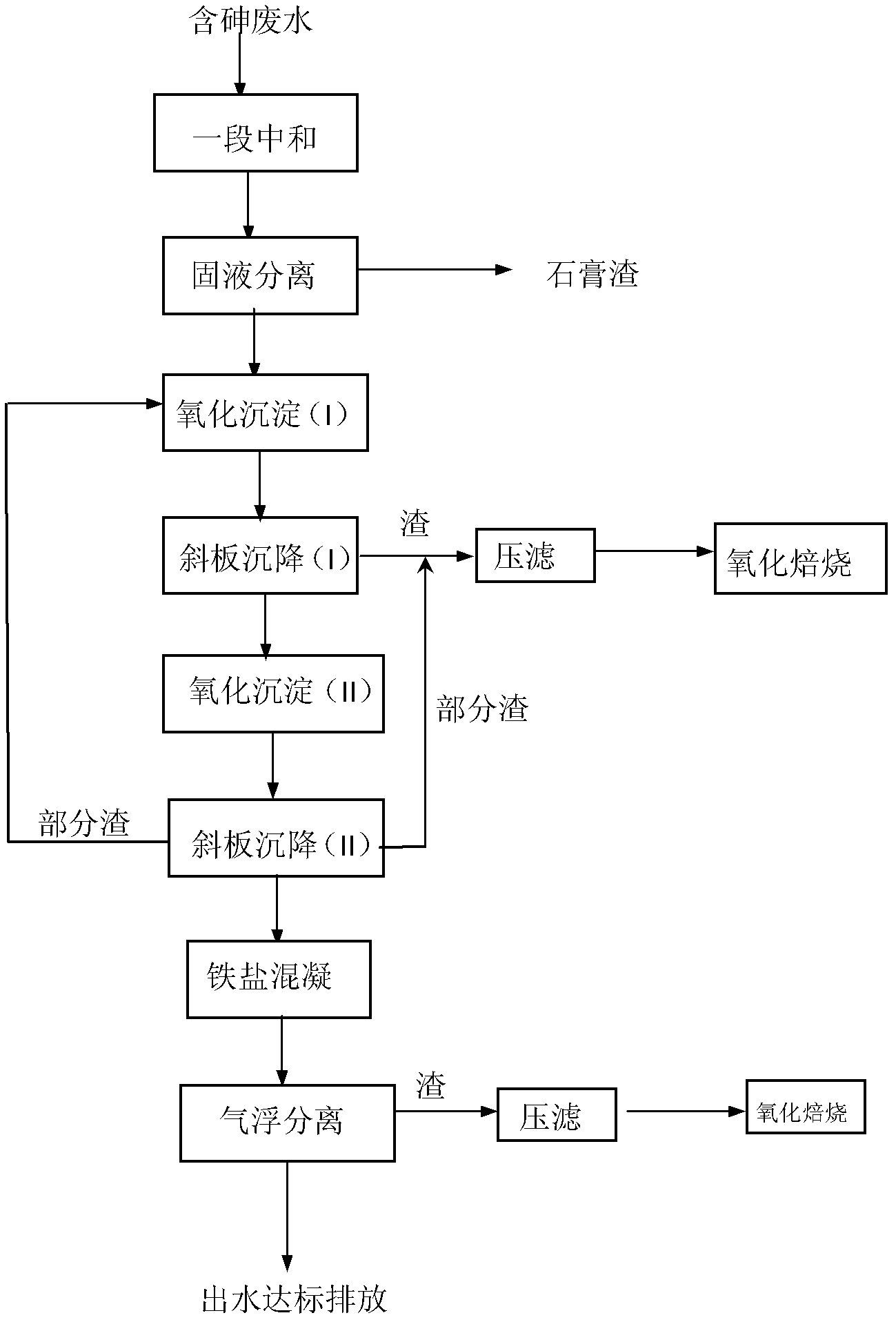

[0033] The present invention is aimed at the specific embodiment of the application of the arsenic-containing wastewater discharged from the sulfuric acid workshop of the copper smelter, and the treatment capacity of the arsenic-containing wastewater is 10m 3 / h, the acid concentration is 6%, and the waste water arsenic (As) content reaches 4.3g / L; Adopt the inventive method to carry out process flow (as figure 1 shown) as follows:

[0034] (1) In the first stage of pH neutralization adjustment, the pH is adjusted by adding lime milk to the arsenic-containing wastewater, and the pH is adjusted to 2, and solid-liquid separation is performed to obtain gypsum and arsenic-containing wastewater.

[0035] (2) Oxidation precipitation (I), add lime milk mixed reaction to the arsenic-containing wastewater after the neutralization of the first section and add calcium hypochlorite simultaneously, control the reaction pH end point value to be 10, after the stirring reaction is completed, ...

Embodiment 2

[0041]The present invention is aimed at the specific embodiment of the application of the arsenic-containing wastewater discharged from the sulfuric acid workshop of the copper smelter, and the treatment capacity of the arsenic-containing wastewater is 10m 3 / h, acid concentration is 6%, and waste water arsenic (As) content reaches 4.9g / L; Adopt the inventive method to carry out process flow (as figure 1 shown) as follows:

[0042] (1) In the first stage of pH neutralization adjustment, the pH value is adjusted by adding milk of lime to the arsenic-containing wastewater, the pH is adjusted to 3, and solid-liquid separation is performed to obtain gypsum and arsenic-containing wastewater.

[0043] (2) Oxidation precipitation (I), add lime milk mixed reaction to the arsenic-containing waste water after the neutralization of the first section and add calcium hypochlorite simultaneously, control the reaction pH end point value to be 12, after the stirring reaction is completed, the...

Embodiment 3

[0049] The present invention is aimed at the specific embodiment of the application of the arsenic-containing wastewater discharged from the sulfuric acid workshop of the copper smelter, and the treatment capacity of the arsenic-containing wastewater is 10m 3 / h, acid concentration is 8%, and waste water arsenic (As) content reaches 5.3g / L; Adopt the inventive method to carry out process flow (as figure 1 shown) as follows:

[0050] (1) In the first stage of pH neutralization adjustment, the pH value is adjusted by adding milk of lime to the arsenic-containing wastewater, and the pH is adjusted to 3, and solid-liquid separation is performed to obtain gypsum and arsenic-containing wastewater.

[0051] (2) Oxidation precipitation (I), add lime milk mixed reaction to the arsenic-containing wastewater after the neutralization of the first section and add chlorine dioxide simultaneously, control the reaction pH end point value to be 11, after the stirring reaction is completed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com