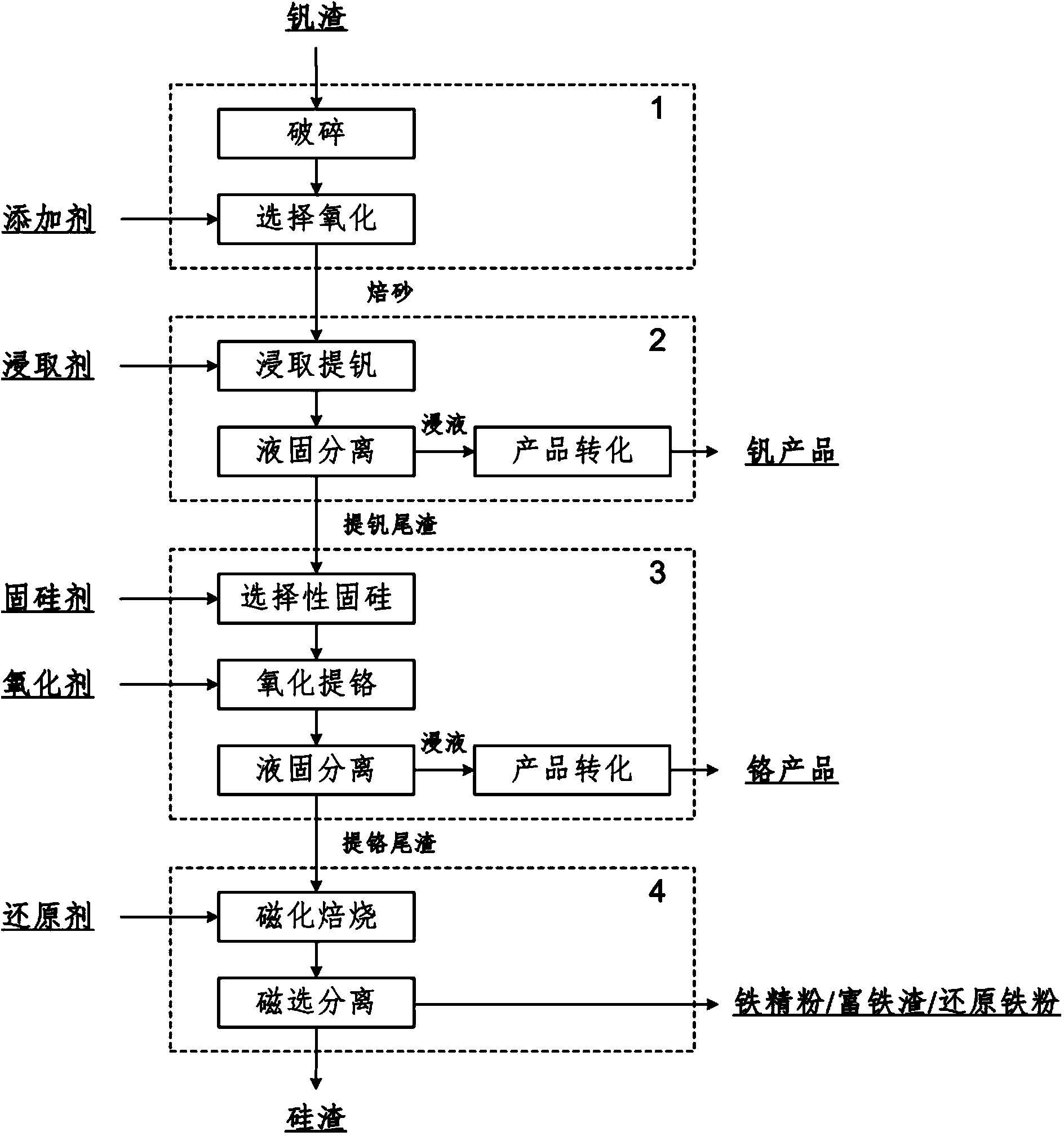

Clean process method for extracting vanadium, chromium and iron from vanadium slag step by step

A process method, a technology for extracting vanadium tailings, applied in the field of chromium, high-efficiency step-by-step extraction of vanadium and iron in vanadium-chromium slag, and can solve the problem of high process energy consumption, incomplete separation of vanadium and chromium, unfavorable product conversion, etc. problem, to achieve the effect of high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The vanadium-chromium slag used contains V8.06wt.%, Cr1.35wt.%, TFe26.30wt%, Si7.03wt%, Ca1.07wt%, Mg1.68wt%.

[0042] (1) After 50g of vanadium-chromium slag is crushed, add calcium carbonate and vanadium slag to mix the ingredients, and control the calcium carbonate and V in the mixture. 2 o 5 The molar ratio is 0.8, and then oxidized at 800°C for 90 minutes to obtain calcined sand;

[0043] (2) Add calcined sand to 250g / L ammonium carbonate solution, react at 140°C for 2.5h, obtain ammonium metavanadate solution and vanadium extraction tailings after liquid-solid separation; obtain ammonium metavanadate after cooling and crystallizing the ammonium metavanadate solution crystal;

[0044] (3) Add vanadium extraction tailings and quicklime to 8% sodium hydroxide solution, and react at 90°C for 2h to selectively solidify silicon; After reacting for 6 hours, sodium chromate alkaline solution and chromium extraction tailings were obtained after liquid-solid separation; ...

Embodiment 2

[0048] The vanadium-chromium slag used contains V8.40wt.%, Cr1.37wt.%, TFe23.34wt%, Si6.46wt%, Ca1.05wt%, Mg1.75wt%.

[0049] (1) After 50g of vanadium-chromium slag is crushed, it is oxidized at 900°C for 60 minutes to obtain calcined sand;

[0050] (2) Add calcined sand to 300g / L ammonium bicarbonate solution, react at 150°C for 3 hours, and obtain ammonium metavanadate solution and vanadium extraction tailings after liquid-solid separation; ammonium metavanadate solution is obtained after cooling and crystallization of ammonium metavanadate solution Crystals, ammonium metavanadate crystals are thermally decomposed to produce vanadium pentoxide;

[0051] (3) Add vanadium extraction tailings and milk of lime to 12% sodium hydroxide solution, react at 70°C for 3 hours to selectively solidify silicon, and then perform liquid-solid separation. The filtrate is recycled for leaching of silicon, and hydrogen oxide is added to the filter residue Sodium is roasted at 900°C for 3 hou...

Embodiment 3

[0055] The vanadium-chromium slag used contains V7.31wt.%, Cr10.18wt.%, TFe35.30wt%, Si5.61wt%, Ca1.62wt%, Mg0.618wt%.

[0056] (1) After 50g of vanadium-chromium slag is crushed, it is oxidized at 900°C for 60 minutes to obtain calcined sand;

[0057] (2) Add calcined sand to 150g / L ammonium nitrate solution, react at 150°C for 3 hours, obtain ammonium metavanadate solution and vanadium extraction tailings after liquid-solid separation; obtain ammonium metavanadate crystals after cooling and crystallizing the ammonium metavanadate solution , ammonium metavanadate crystals are thermally decomposed to produce vanadium pentoxide;

[0058] (3) Add vanadium extraction tailings and quicklime to 15% sodium hydroxide solution, react at 60°C for 2h to selectively solidify silicon, then add sodium hydroxide to adjust the alkali concentration of the solution to 40%, and place it under an oxygen atmosphere at 260°C After reacting for 1.5 hours, sodium chromate alkaline solution and chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com