Preparation method of biomass charcoal-based magnetic activated sludge and application of biomass charcoal-based magnetic activated sludge to uranium-bearing wastewater treatment

A biochar and activated sludge technology, applied in radioactive purification, alkali metal compounds, other chemical processes, etc., can solve problems such as unstable structure, reduced specific surface area, low magnetic strength, etc. It is easy to achieve and overcome the heating conditions The effect of low porosity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of biochar

[0039] After the rice husk is dried under natural conditions, it is pulverized by a pulverizer, put into a muffle furnace at 400°C, decomposed by heat under anaerobic sealing conditions, and then left at a constant temperature, cooled, and ground to obtain powdery biomass carbon.

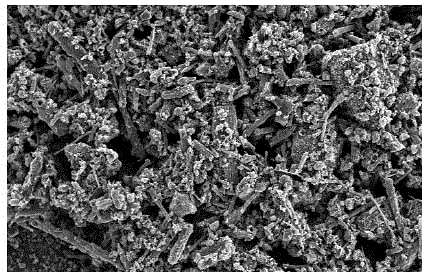

[0040] (2) Biomass carbon-based magnetic nano-Fe 3 o 4 preparation of

[0041] Weigh 1.5g FeSO 4 .7H 2 O and 2.9gFeCl 3 .6H 2 O, and according to Fe 2+ with Fe 3+ The molar ratio of the solution is 1:2, put it in a 500mL three-neck beaker with 150mL deionized water, add 1.5g sucrose, and then place it in a constant temperature water bath at 50°C for 30min with magnetic stirring to form a uniformly mixed iron ion solution. Then add 6g of biomass carbon powder to the iron ion solution, continue magnetic stirring at room temperature for 20 minutes, and add ammonia water with a mass concentration of 25% dropwise as a precipitant, adjust the pH value of the so...

Embodiment 2

[0050] (1) Preparation of biochar

[0051] After the peanut shells are dried under natural conditions, crushed by a pulverizer, placed in a muffle furnace at 350°C, decomposed by heat under anaerobic sealing conditions, left at a constant temperature, cooled, and ground to obtain powdery biomass charcoal .

[0052] (2) Biomass carbon-based magnetic nano-Fe 3 o 4 preparation of

[0053] Weigh 1.495g FeSO 4 .7H 2 O and 1.45gFeCl 3 .6H 2 O, and according to Fe 2+ with Fe 3+ The molar ratio of the solution is 1:1, put it in a 500mL three-neck beaker filled with 150mL deionized water, add 1g of glucose, and then place it in a constant temperature water bath at 50°C for 30min with magnetic stirring to form a uniformly mixed iron ion solution. Then add 5.5g of biochar powder to the iron ion solution, continue magnetic stirring at room temperature for 20min, and add dropwise ammonia water with a mass concentration of 25% as a precipitant, adjust the pH value of the solution t...

Embodiment 3

[0062] (1) Preparation of biochar

[0063] After the sawdust is dried in the sun under natural conditions, it is pulverized by a pulverizer, put into a muffle furnace at 450°C, decomposed by heat under anaerobic sealing conditions, left at a constant temperature, cooled, and ground to obtain powdery biomass carbon.

[0064] (2) Biomass carbon-based magnetic nano-Fe 3 o 4 preparation of

[0065] Weigh 1.495g FeSO 4 .7H 2 O and 2.17 g FeCl 3 .6H 2 O, and according to Fe 2+ with Fe 3+ The molar ratio is 1:1.5, placed in a 500mL three-neck beaker filled with 150mL deionized water, and then 2g of maltose was added, and then placed in a constant temperature water bath at 50°C for 30min with magnetic stirring to form a uniformly mixed iron ion solution. Then add 5g of biomass charcoal powder to the iron ion solution, continue magnetic stirring at room temperature for 20min, and add ammonia water with a mass concentration of 25% dropwise as a precipitant, adjust the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com