Method for producing potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar

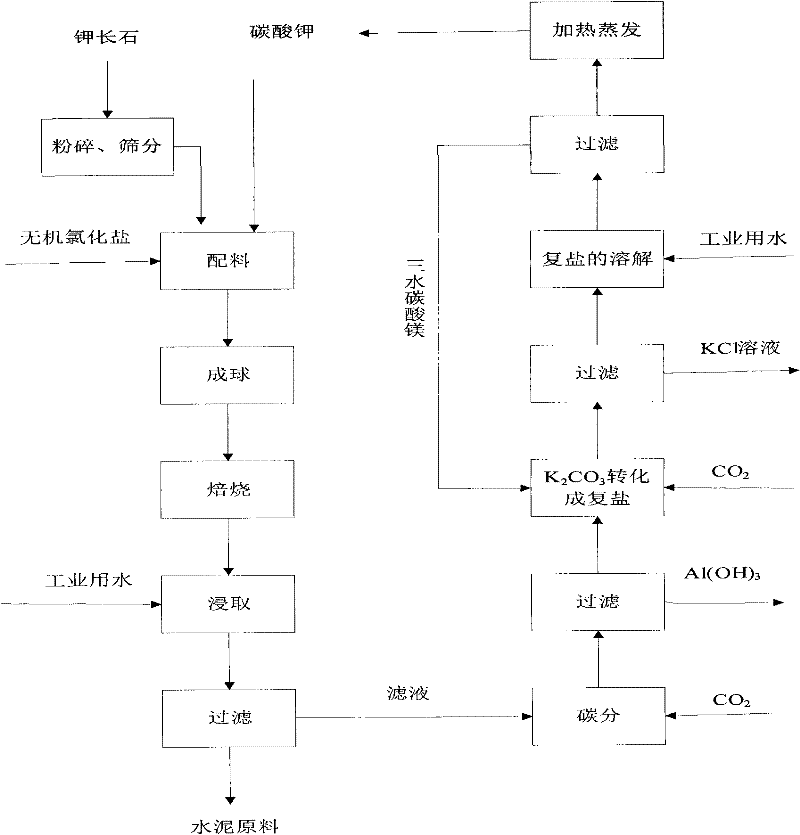

A technology of potassium feldspar and alumina, which is applied in the field of comprehensive utilization of potassium feldspar to produce potash fertilizer and alumina, can solve the problems of ineffective utilization, low aluminum dissolution rate, high equipment requirements, etc., and achieves the improvement of comprehensive utilization effect, The effect of saving raw materials and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

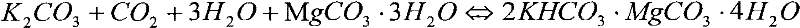

[0047] Potassium feldspar (K 2 O content 9.5%, Al 2 o 3 Content 10.3%) and calcium chloride are ground to 1mm particle size, according to mass ratio potassium feldspar: calcium chloride: potassium carbonate=1:1:2 Weigh the material in the crucible, after mixing into balls, in the muffle furnace Calcination at 800°C for 2 hours, after cooling down to room temperature, take out the crucible and wash it with deionized water, move the washing solution to the reactor for water leaching experiment for 2 hours; then filter the leaching solution and fully wash the filter residue; The filtrate was transferred to a 500mL volumetric flask, and the K content of the sample was analyzed after constant volume. Take 200mL of the filtrate and pass through it with a sufficient amount of CO 2 , and then separate the precipitate from the filtrate, and carry out accurate weighing to calculate the content of Al therein.

[0048] After detection and calculation, the dissolution rate of K is 71.1...

Embodiment 2

[0050] Potassium feldspar (K 2 O content 9.5%, Al 2 o 3 Content 10.3%) and calcium chloride are ground to 1mm particle size, according to mass ratio potassium feldspar: calcium chloride: potassium carbonate=1:2:2 Weigh the material in the crucible, after mixing into balls, in the muffle furnace Calcination at 800°C for 2 hours, after cooling down to room temperature, take out the crucible and wash it with deionized water, move the washing solution to the reactor for water leaching experiment for 2 hours; then filter the leaching solution and fully wash the filter residue; The filtrate was transferred to a 500mL volumetric flask, and the K content of the sample was analyzed after constant volume. Take 200mL of the filtrate and pass through it with a sufficient amount of CO 2 , and then separate the precipitate from the filtrate, and carry out accurate weighing to calculate the content of Al therein.

[0051] After testing, the dissolution rate of K was 76.2%, and that of Al...

Embodiment 3

[0053] Potassium feldspar (K 2 O content 9.5%, Al 2 o 3 Content 10.3%) and calcium chloride are ground to 1mm particle size, according to mass ratio potassium feldspar: calcium chloride: potassium carbonate=1:1:3 Weigh the material in the crucible, after mixing into balls, in the muffle furnace Calcination at 900°C for 2 hours, after cooling down to room temperature, take out the crucible and wash it with deionized water, move the washing liquid to the reactor for water leaching experiment for 2 hours; then filter the leachate and fully wash the filter residue; The filtrate was transferred to a 500mL volumetric flask, and the K content of the sample was analyzed after constant volume. Take 200mL of the filtrate and pass through it with a sufficient amount of CO 2 , and then separate the precipitate from the filtrate, and carry out accurate weighing to calculate the content of Al therein.

[0054] After testing, the dissolution rate of K was 80.4%. The dissolution rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com