Rubber-polytetrafluoroethylene compounded sealing ring

A polytetrafluoroethylene, composite technology, applied in the direction of engine components, piston rings, mechanical equipment, etc., can solve the problems of shortened service life, low elasticity, use leakage, etc., and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The rubber-polytetrafluoroethylene composite sealing ring of the present invention will be further described in detail below with reference to the accompanying drawings.

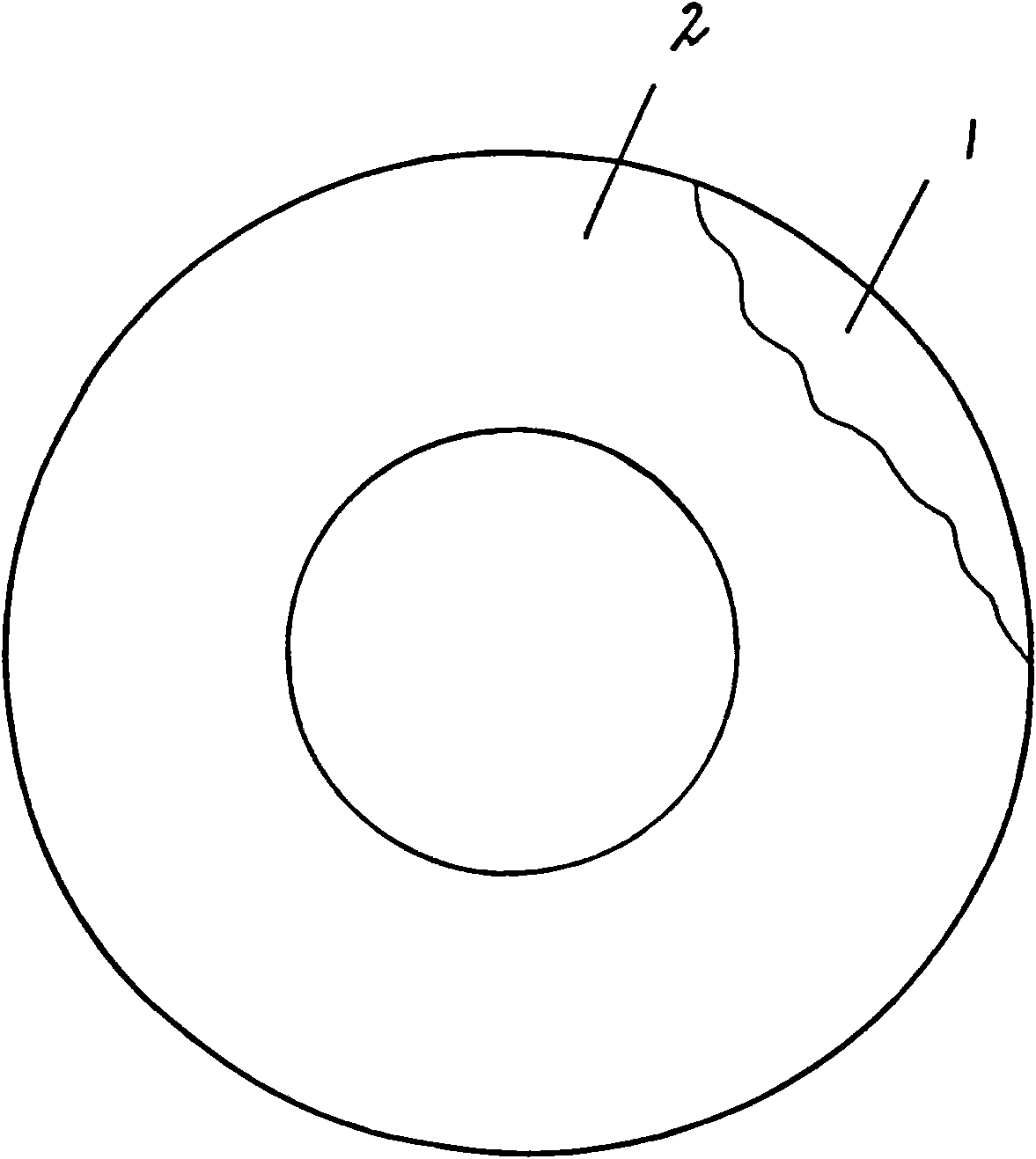

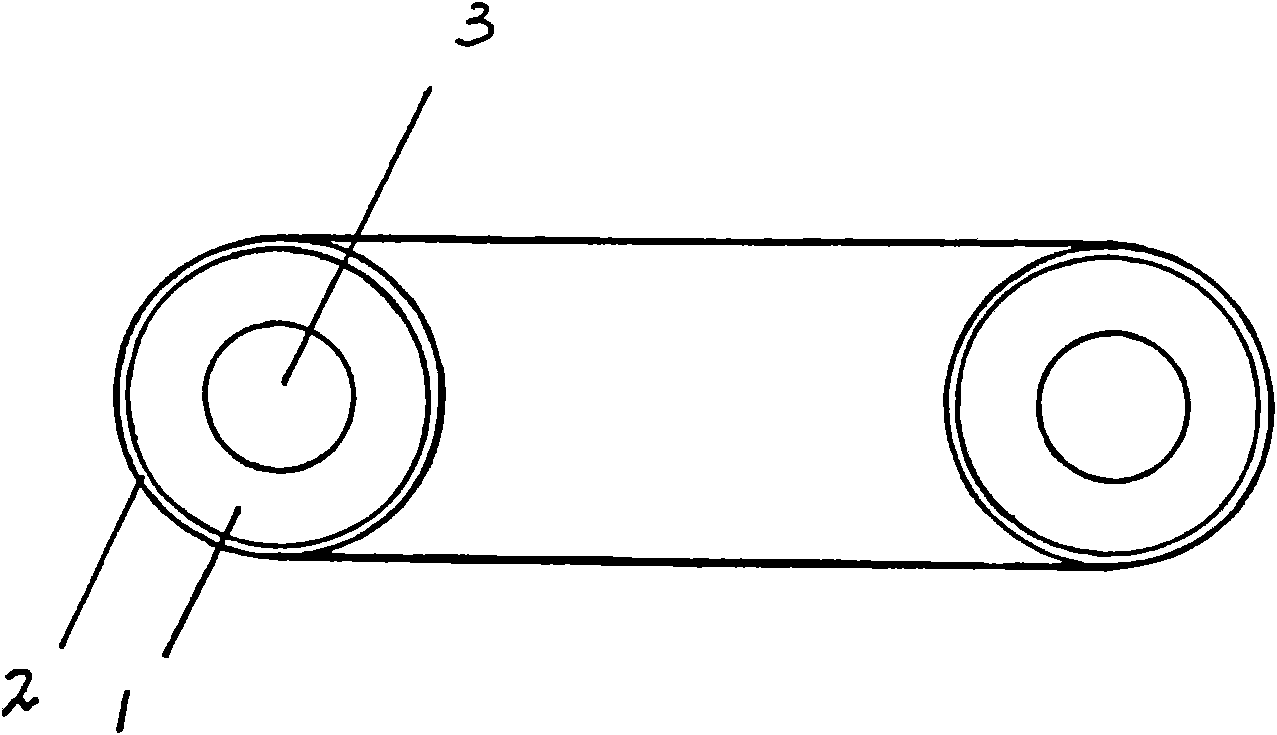

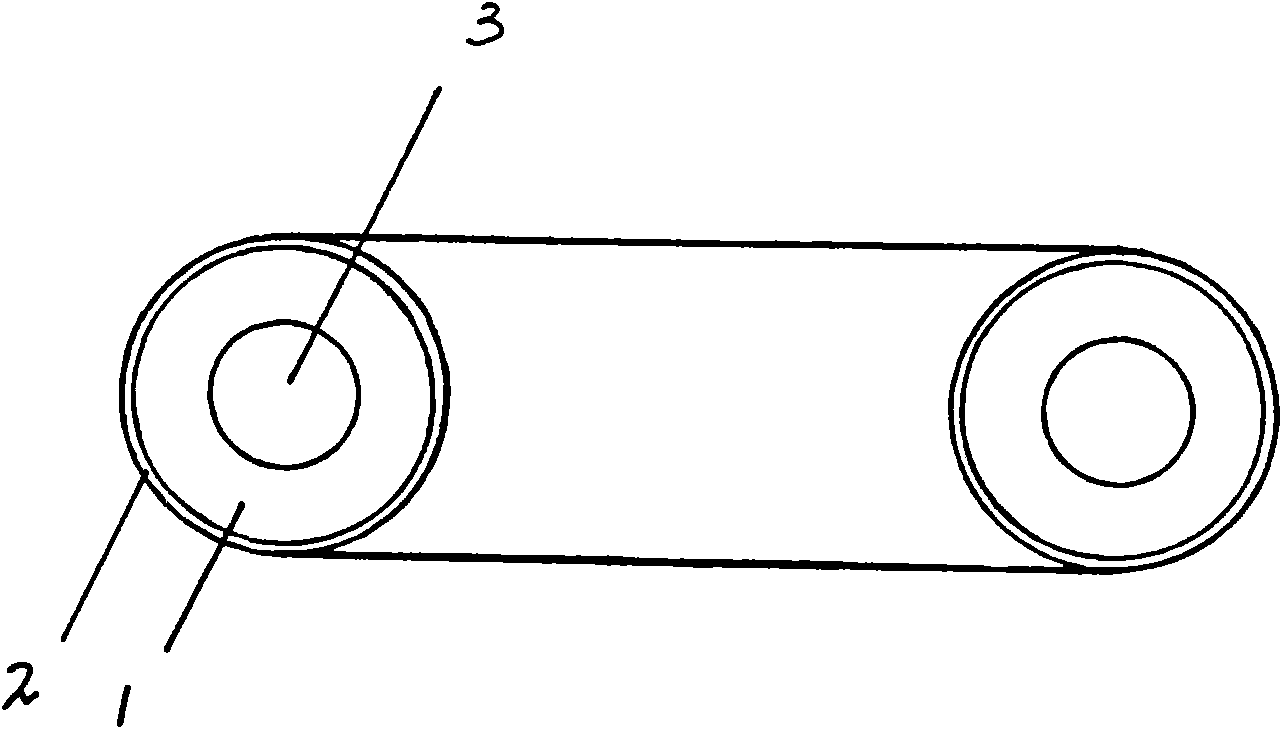

[0018] see figure 1 and figure 2 , the rubber-polytetrafluoroethylene composite sealing ring of the invention includes an annular body 1, the annular body 1 is a silicone rubber annular body or a fluorine rubber annular body, and the described annular body 1 is hollow 3 rings, the hollow 3 rings are wrapped with a polytetrafluoroethylene felt layer 2.

[0019] Modifying the annular body 1 of the rubber-polytetrafluoroethylene composite sealing ring of the present invention into a rectangular shape or a square shape also belongs to the protection category of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com