Fluororubber/ N,N'-m-phenylene bismaleimide composite

A technology of phenylene bismaleimide and composite materials, which is applied in the field of fluororubber/N,N'-m-phenylene bismaleimide composite materials, can solve the problem of large decline in mechanical properties and resistance Problems such as poor radiation performance and poor processing performance can achieve the effect of improving high temperature resistance and medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

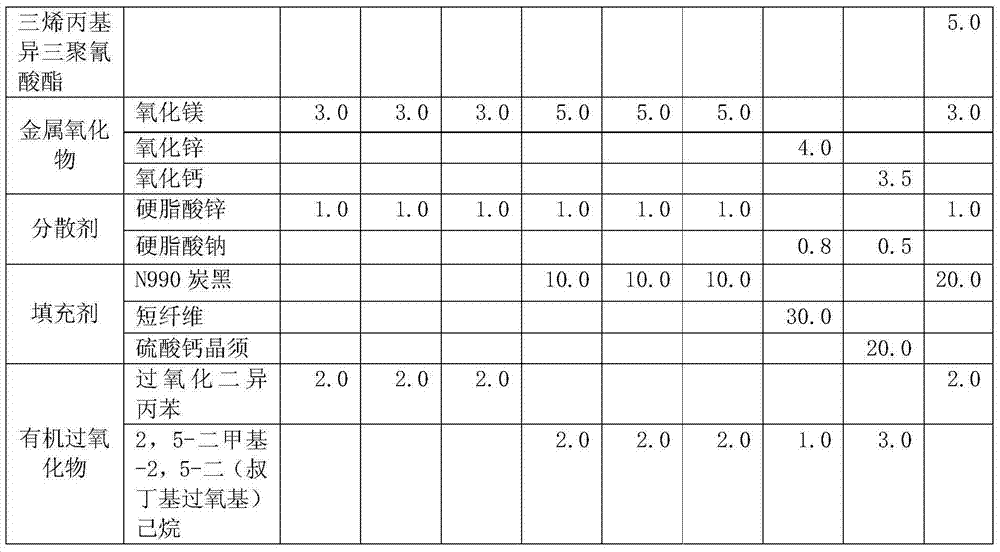

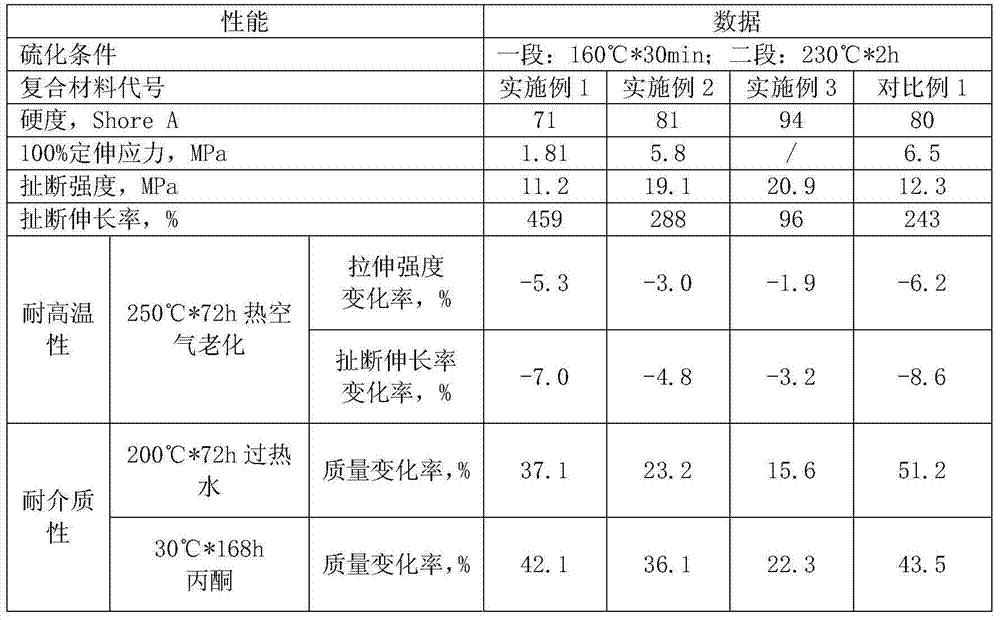

Embodiment 1

[0032] Carry out rubber mixing (mechanical blending method) according to the components specified in Table 1 below, and the mixing of rubber materials is carried out in two stages. The first stage of mixing is carried out in the F-type or GK type internal mixer, and the second stage of mixing is carried out in the double-roller open mill. The order of feeding during one-stage mixing is fluororubber, N,N'-m-phenylene bismaleimide, metal oxide, dispersant (if any), filler (if any). The organic peroxide is added during the second-stage mixing. The performance tests of the obtained rubber compounds are carried out, and the test results are listed in Table 2.

Embodiment 2

[0034] Carry out rubber mixing by each component specified in the following table 1, the mixing of rubber material is the same as embodiment 1, has listed test result in table 2.

Embodiment 3

[0036] Carry out rubber mixing by each component specified in the following table 1, the mixing of rubber material is the same as embodiment 1, has listed test result in table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com