Wear-resisting epoxy paint

A technology of wear-resistant rings and coatings, applied in the field of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Component A of the paint includes 20 parts of mixed epoxy resin, 8 parts of diluent, 1 part of silane coupling agent, 20 parts of iron-based alloy powder, 20 parts of alumina powder, 15 parts of silicon carbide, 10 parts of porcelain powder, glass 4 parts of scales, 1 part of carbon black.

[0020] Component B: 70 parts of high hardness and wear-resistant epoxy curing agent, 30 parts of epoxy accelerator.

example 2

[0022] Component A of the paint includes 25 parts of mixed epoxy resin, 5 parts of diluent, 3 parts of silane coupling agent, 10 parts of iron-based alloy powder, 10 parts of alumina powder, 20 parts of silicon carbide, 14 parts of porcelain powder, glass 2 parts of scales, 2 parts of carbon black.

[0023] Component B: 75 parts of high hardness and wear-resistant epoxy curing agent, 25 parts of epoxy accelerator.

example 3

[0025] Component A of the coating includes 45 parts of mixed epoxy resin, 2 parts of diluent, 4 parts of silane coupling agent, 30 parts of iron-based alloy powder, 30 parts of alumina powder, 5 parts of silicon carbide, 20 parts of porcelain powder, glass 1 part of scale, 4 parts of carbon black.

[0026] Component B: 80 parts of high hardness and wear-resistant epoxy curing agent, 20 parts of epoxy accelerator.

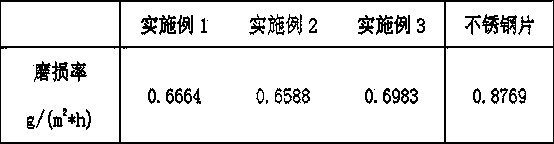

[0027] In above embodiment 1~3

[0028] Further can: described mixed epoxy resin is E-51 epoxy resin and E-44 epoxy resin, wherein E-51 epoxy resin consumption is 4060% of mixed epoxy resin gross weight, E-44 epoxy resin consumption It is 4060% of the total weight of the mixed epoxy resin.

[0029] Further can: described high hardness wear-resistant epoxy curing agent is modified aromatic amine epoxy curing agent and polyamide epoxy curing agent, wherein the amount of modified aromatic amine epoxy curing agent is high hardness wear-resistant epoxy curing agent 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com