Polyaspartic acid ester type sealant for oil pipeline head and preparation method thereof

An aspartate and petroleum pipeline technology, applied in the field of polyurea, can solve the problems of liquid medium resistance, poor oil resistance, poor anti-aging ability, poor weather resistance, etc., and achieves obvious effects, strong constructability, and reduced usage. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

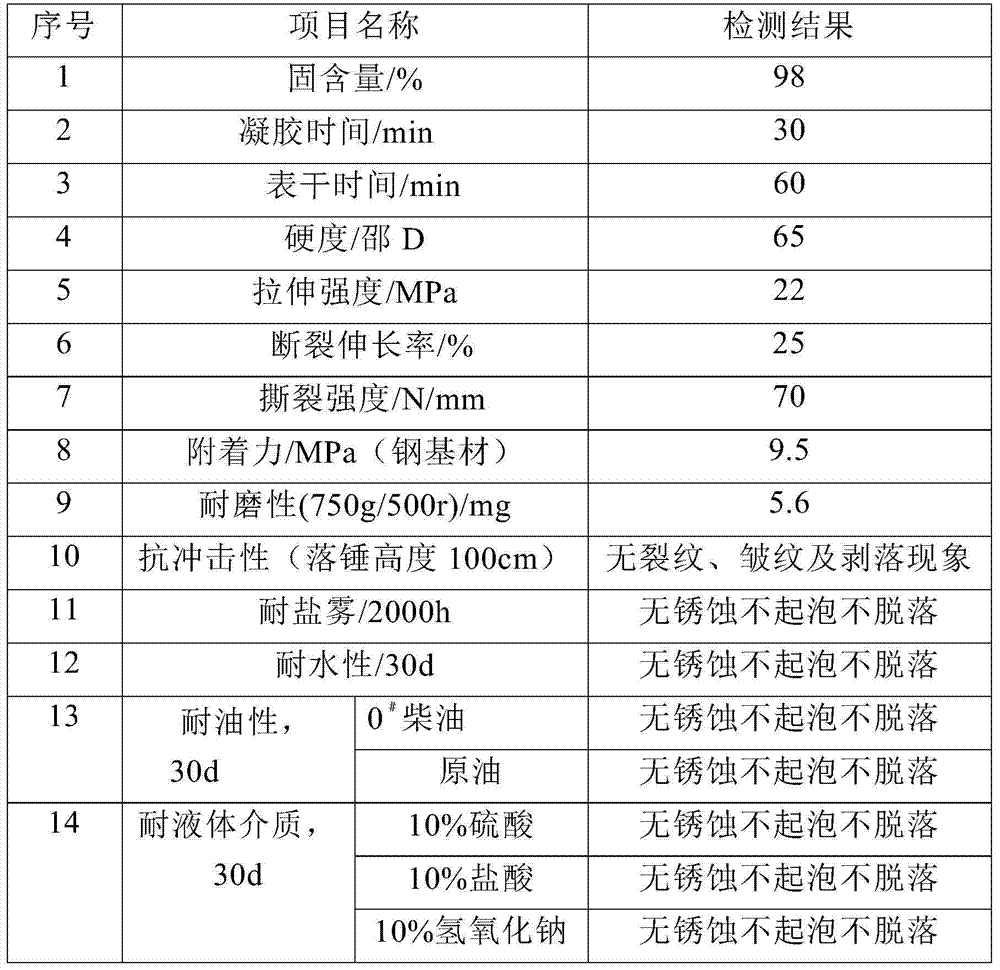

Examples

Embodiment 1

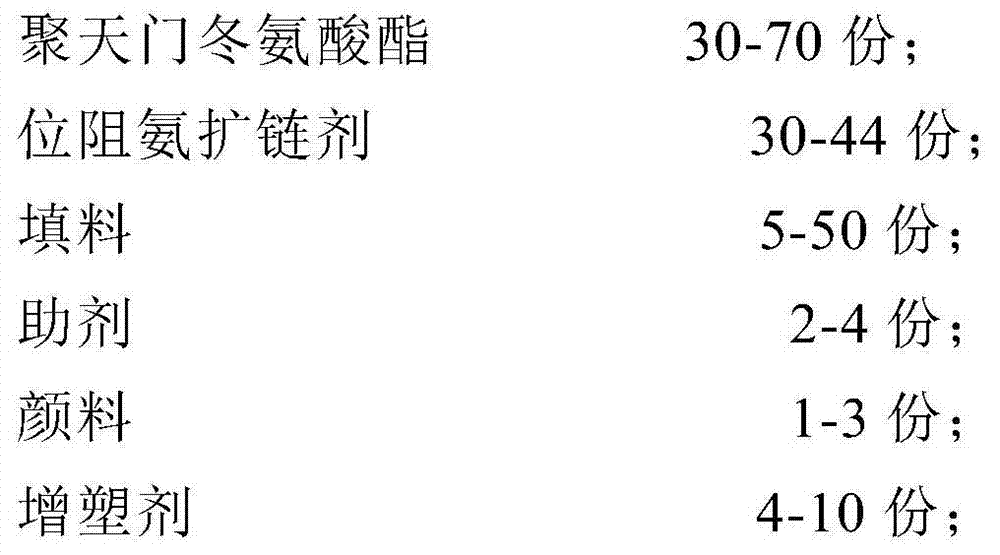

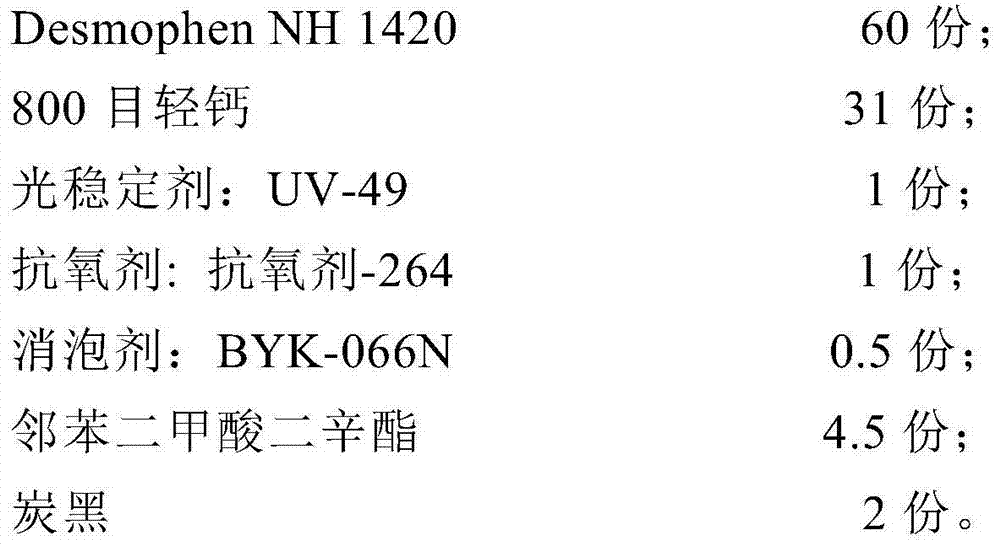

[0042] This embodiment discloses a polyaspartic acid ester type sealant for oil pipeline head, which includes the following components by weight ratio:

[0043] A component:

[0044] Hexamethylene diisocyanate trimer HDI 65.7 parts;

[0045] Polytetrahydrofuran ether polyol PTMG-1000 34.3 parts;

[0046] B component:

[0047]

[0048] The sealant is prepared by the following steps:

[0049] Preparation of component A: Add 34.3g of polytetrahydrofuran ether polyol PTMG-1000 into the container, stir the liquid material at a low speed for 5 minutes, heat it to 110-120°C, turn on the vacuum pump, and the vacuum degree is -0.1-0.08 MPa, vacuum dehydration for 2 hours, remove a small amount of water contained in the raw material, detect that the water content is below 3 / 10,000, and cool until the temperature of the liquid material is about 25°C. Add 65.7g of hexamethylene diisocyanate HDI trimer into the container, stir and react at room temperature for 1 hour, slowly raise t...

Embodiment 2

[0058] This embodiment discloses a polyaspartic acid ester type sealant for oil pipeline head, which includes the following components by weight ratio:

[0059] A component:

[0060] 50.4 parts of 4,4'-dicyclohexylmethane diisocyanate HMDI;

[0061] Polyoxypropylene ether polyol PPG-1000 49.6 parts;

[0062] B component:

[0063]

[0064] The sealant is prepared by the following steps:

[0065] Preparation of component A: Add 49.6g of polyoxypropylene ether polyol PPG-1000 into the container, stir the liquid material at a low speed for 5 minutes, heat it to 110~120℃, turn on the vacuum pump, and the vacuum degree is -0.1~- 0.08MPa, vacuum dehydration for 2 hours, remove a small amount of water contained in the raw material, the water content is detected to be below 3 / 10,000, and cooled until the temperature of the liquid material is about 25 °C. Add 50.4g of 4,4'-dicyclohexylmethane diisocyanate HMDI into the container, stir and react at room temperature for 1 hour, slo...

Embodiment 3

[0073] This embodiment discloses a polyaspartic acid ester type sealant for oil pipeline head, which includes the following components by weight ratio:

[0074] A component:

[0075] 69.3 parts of hexamethylene diisocyanate HDI trimer;

[0076] Polyoxypropylene ether polyol PPG-1000 30.7 parts;

[0077] B component:

[0078]

[0079] The sealant is prepared by the following steps:

[0080] Preparation of component A: Add 30.7g of polyoxypropylene ether polyol PPG-1000 into the container, stir the liquid material at a low speed for 5 minutes, heat it to 110~120℃, turn on the vacuum pump, and the vacuum degree is -0.1~- 0.08MPa, vacuum dehydration for 2 hours, remove a small amount of water contained in the raw material, the water content is detected to be below 3 / 10,000, and cooled until the temperature of the liquid material is about 25 °C. Add 69.3g of hexamethylene diisocyanate HDI trimer into the container, stir and react at room temperature for 1 hour, slowly raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com