High-oil-resistance polyurethane adhesive

A polyurethane adhesive, oil resistance technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of limited application scope and high cost, achieve high peel strength and medium resistance, good The effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

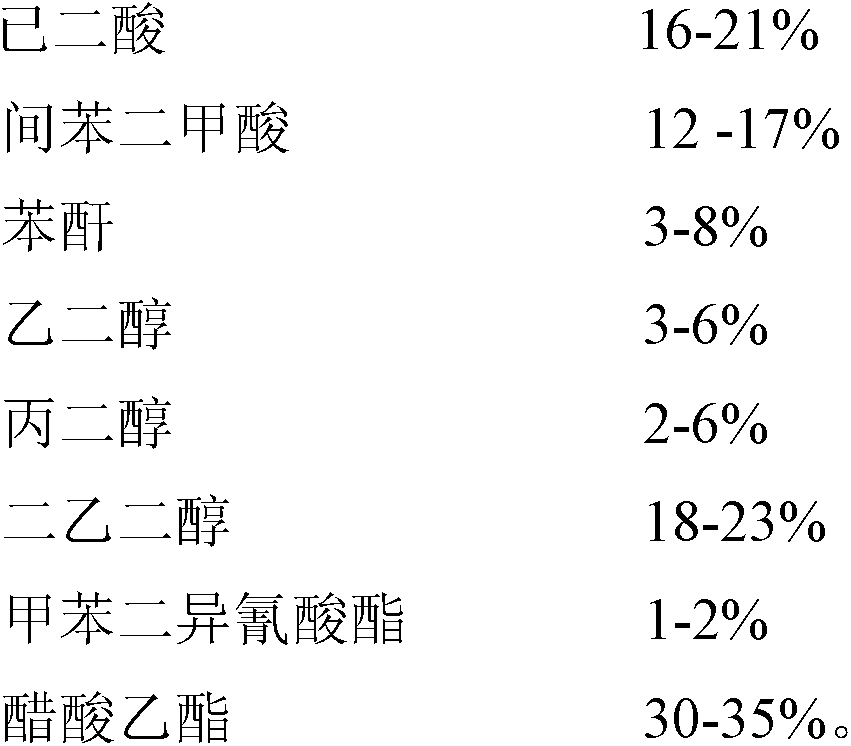

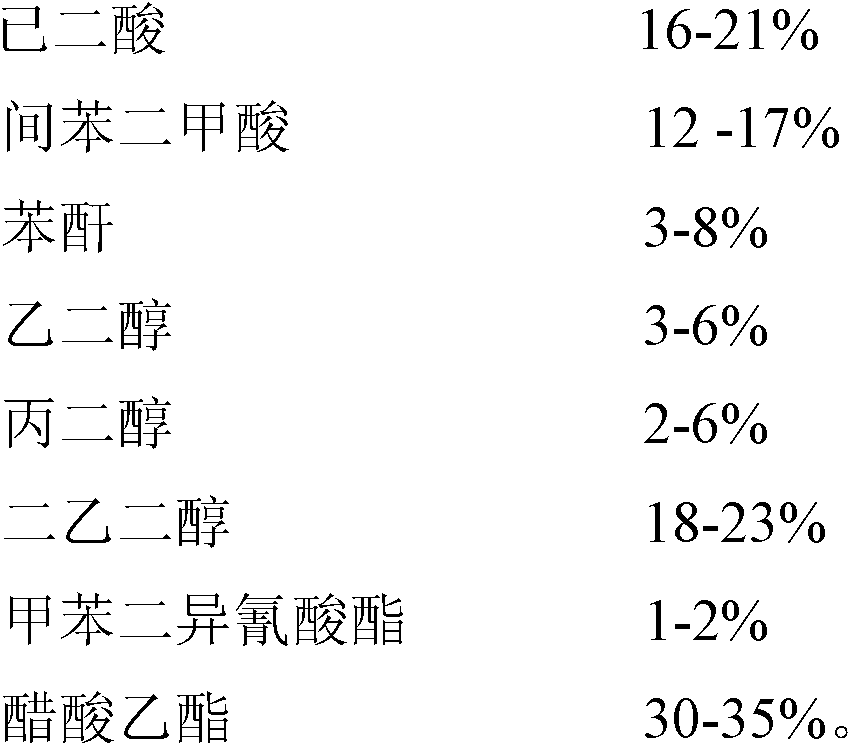

Method used

Image

Examples

Embodiment 1

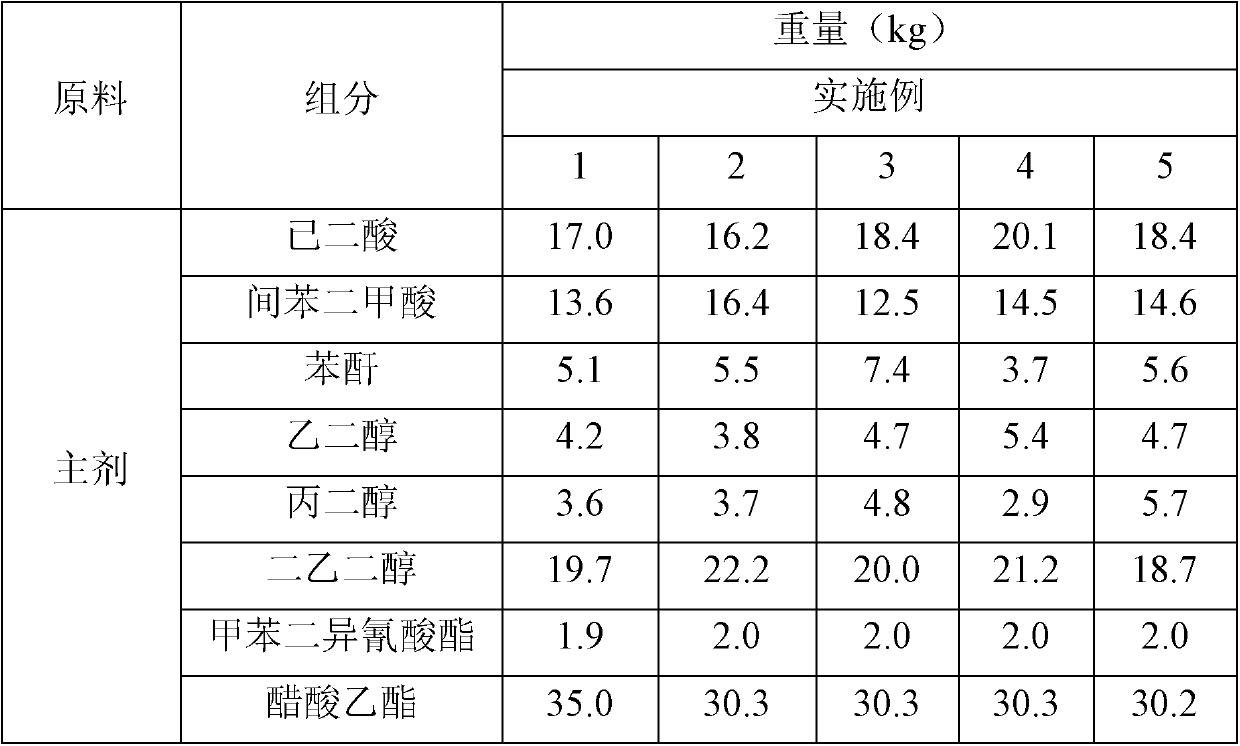

[0029] Prepare the main ingredient: (1) According to the ratio in Table 1, mix the adipic acid, isophthalic acid, phthalic anhydride, ethylene glycol, propylene glycol, and diethylene glycol in the main ingredient, and then perform esterification reaction at 150-230°C , the esterification was carried out for 10 hours (during the reaction, the temperature was gradually increased from 150°C to 230°C according to the degree of reaction), and the reaction was stopped; (2) The material liquid obtained from the esterification of step (1) was placed in a vacuum environment of 0-0.01MPa Carry out polycondensation reaction and react for 5 hours to obtain polyester polyol with an average molecular weight of 5000 and an acid value of 0.40; (3) add toluene diisocyanate chain extender to step (2) and react 4 polyols at 80-110°C After one hour, add ethyl acetate to dilute to obtain a light yellow transparent main agent with a viscosity of 2000 mPa.s (the weight percent content of solids in t...

Embodiment 2

[0033] Prepare the main ingredient: (1) According to the ratio in Table 1, mix the adipic acid, isophthalic acid, phthalic anhydride, ethylene glycol, propylene glycol, and diethylene glycol in the main ingredient, and then perform esterification reaction at 150-230°C , the esterification was carried out for 10 hours (during the reaction, the temperature was gradually increased from 150°C to 230°C according to the degree of reaction), and the reaction was stopped; (2) The material liquid obtained from the esterification of step (1) was placed in a vacuum environment of 0-0.01MPa Carry out polycondensation reaction and react for 5 hours to obtain a polyester polyol with an average molecular weight of 4750 and an acid value of 0.35; (3) add toluene diisocyanate chain extender to step (2) and react 4 polyols at 80-110°C After one hour, add ethyl acetate to dilute to obtain a light yellow transparent main agent with a viscosity of 2200 mPa.s (the weight percent content of solids in...

Embodiment 3

[0037] Prepare the main ingredient: (1) According to the ratio in Table 1, mix the adipic acid, isophthalic acid, phthalic anhydride, ethylene glycol, propylene glycol, and diethylene glycol in the main ingredient, and then perform esterification reaction at 150-230°C , the esterification was carried out for 10 hours (during the reaction, the temperature was gradually increased from 150°C to 230°C according to the degree of reaction), and the reaction was stopped; (2) The material liquid obtained from the esterification of step (1) was placed in a vacuum environment of 0-0.01MPa Carry out polycondensation reaction and react for 5 hours to obtain a polyester polyol with an average molecular weight of 4800 and an acid value of 0.48; (3) add toluene diisocyanate chain extender to step (2) and react 4 polyols at 80-110° C. After one hour, ethyl acetate was added to dilute to obtain a light yellow transparent main agent with a viscosity of 2260 mPa.s (the weight percent content of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com