Preparation method of ultraviolet light curing composite binding agent

A composite adhesive and ultraviolet light technology, which is applied in the direction of grafted polymer adhesives, adhesive types, adhesives, etc., can solve the problems of high toxicity, high viscosity, poor adhesion and medium resistance, etc. Achieve the effect of improving bonding and anti-medium performance, moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment 1 provides a preparation method of an ultraviolet (UV) light-cured composite adhesive, which is used to prepare a high-performance, environmentally friendly UV-cured composite adhesive. The method comprises the following steps:

[0029] (1) Preparation of polyester polyol:

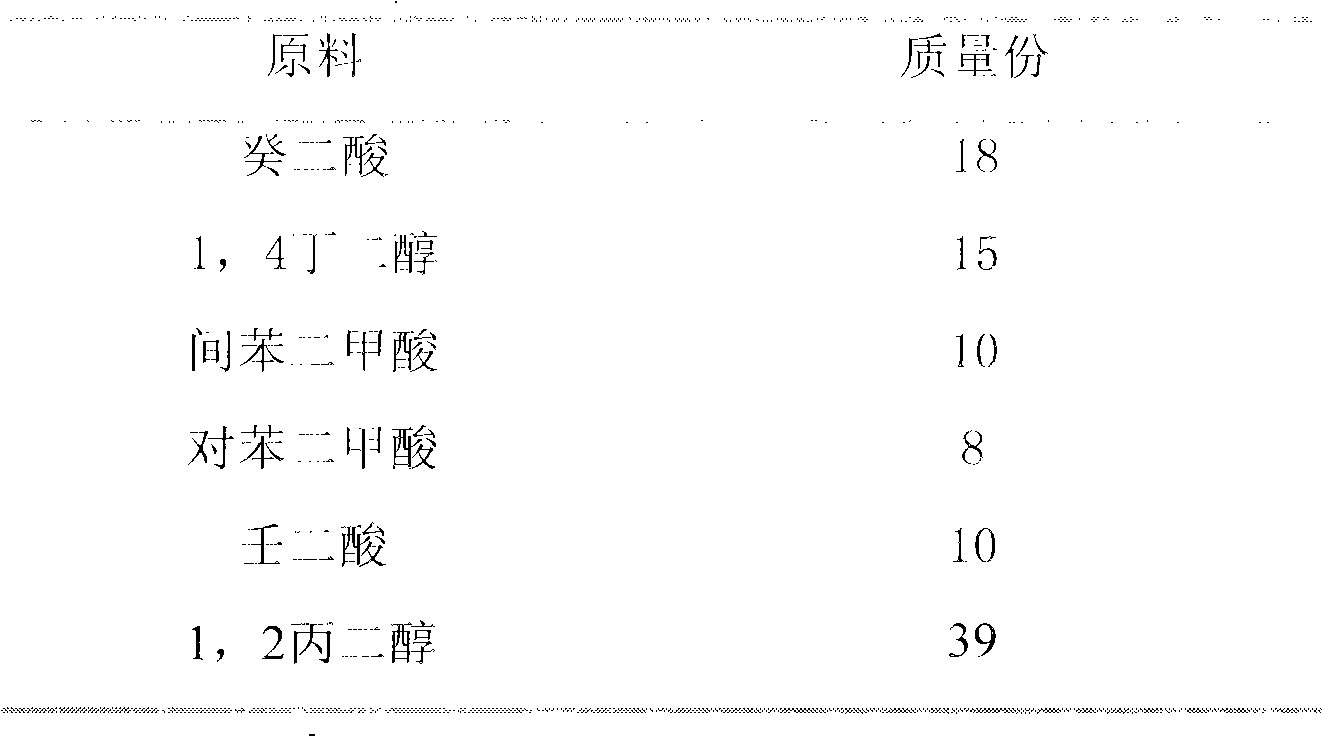

[0030] Prepare each raw material of polyester polyol by mass percentage, comprise:

[0031] Sebacic acid 10-20%, 1,4 butanediol 15-25%, isophthalic acid 5-15%, terephthalic acid 5-10%, azelaic acid 5-15% and 1,2 propylene glycol 30% ~40%;

[0032] a. Primary esterification:

[0033] Add sebacic acid and 1,4-butanediol into the polyester synthesis kettle, heat up to 210-230°C, react for 2-3 hours, and distill 2-4kg of water;

[0034] b. Secondary esterification:

[0035] Add isophthalic acid, terephthalic acid, azelaic acid and 1,2 propylene glycol into the above-mentioned polyester synthesis kettle that has completed one-time esterification, raise the temperature to 210-230°C, an...

Embodiment 2

[0054] This embodiment 2 provides a preparation method of an ultraviolet (UV) light-cured composite adhesive, which is used to prepare a high-performance, environmentally friendly ultraviolet-cured composite adhesive. The method comprises the following steps:

[0055] (1) prepare polyester polyol, get each raw material by following mass percentage:

[0056]

[0057] The preparation method of polyester polyol:

[0058] a. Primary esterification:

[0059] Add sebacic acid and 1,4 butanediol into the polyester synthesis kettle, raise the temperature to 210-230°C, and react for 2-3 hours. The primary esterification is completed. During the primary esterification, the polyester synthesis kettle distills water for 2-3 hours. 4kg;

[0060] b. Secondary esterification:

[0061] Add isophthalic acid, terephthalic acid, azelaic acid and 1,2 propylene glycol into the above-mentioned polyester synthesis kettle that has completed primary esterification, raise the temperature to 210-2...

Embodiment 3

[0074] (1) prepare polyester polyol, get each raw material by following mass percentage:

[0075]

[0076]

[0077] The method for preparing polyester polyol is substantially the same as embodiment 2, and the method that provides with reference to embodiment 2 can prepare polyester polyol;

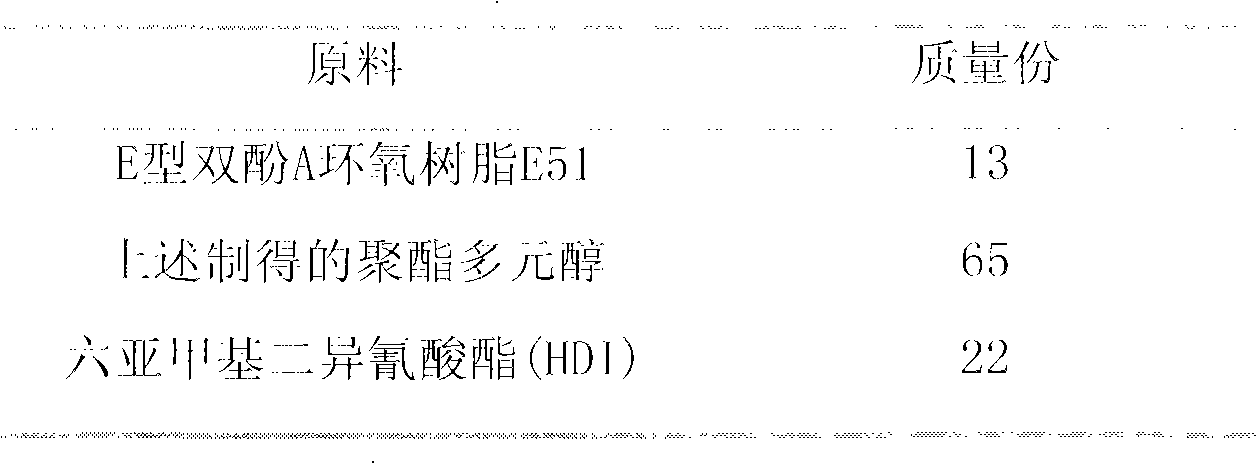

[0078] (2) Preparation of epoxy-modified polyurethane prepolymer:

[0079]

[0080] The preparation method of bad oxygen modified polyurethane prepolymer:

[0081] E-type bisphenol A epoxy resin E20, polyester polyol and terexylylene diisocyanate (XDI) were reacted at 65°C for 3 hours to prepare epoxy-modified polyurethane prepolymer. The -NCO content of the permanent polyurethane prepolymer is 3.9%;

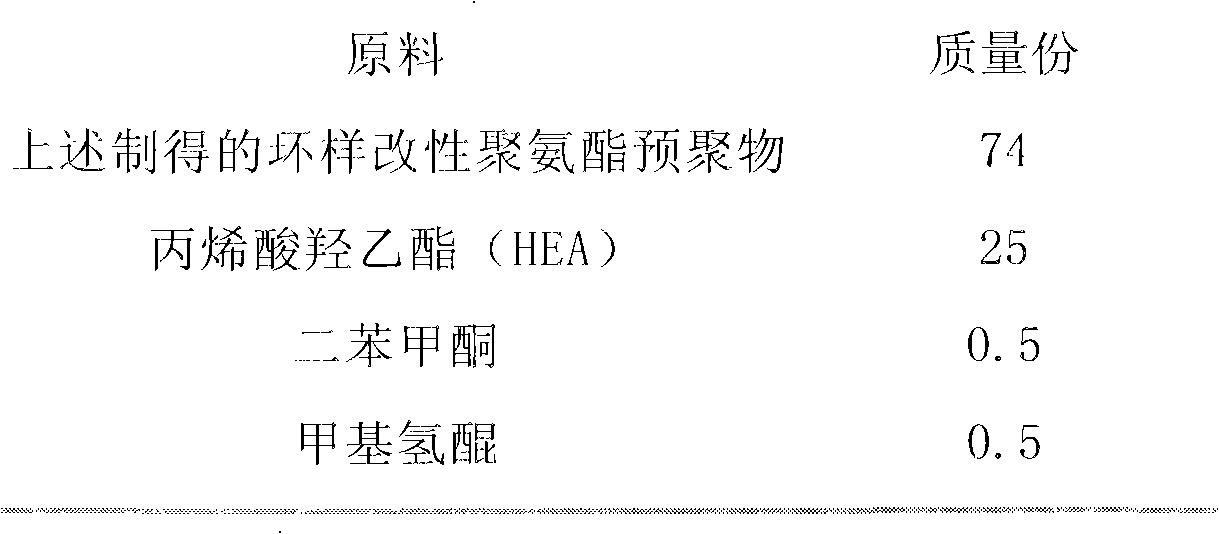

[0082] (3) Preparation of epoxy-modified polyurethane acrylate:

[0083]

[0084] The preparation method of bad oxygen modified polyurethane acrylate:

[0085] React epoxy-modified polyurethane prepolymer and trimethylolpropane triacrylate (TMPTA) at 70°C for 5 to 6 hours, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com