Sealant of silane-terminated polymer and preparation method thereof

A silane-terminated, polymer technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of poor medium resistance, affecting the storage stability of prepolymer sealant, complex polymer preparation process, etc. Problems, to achieve the effect of improving medium resistance and bonding performance, improving storage stability, improving storage stability and medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

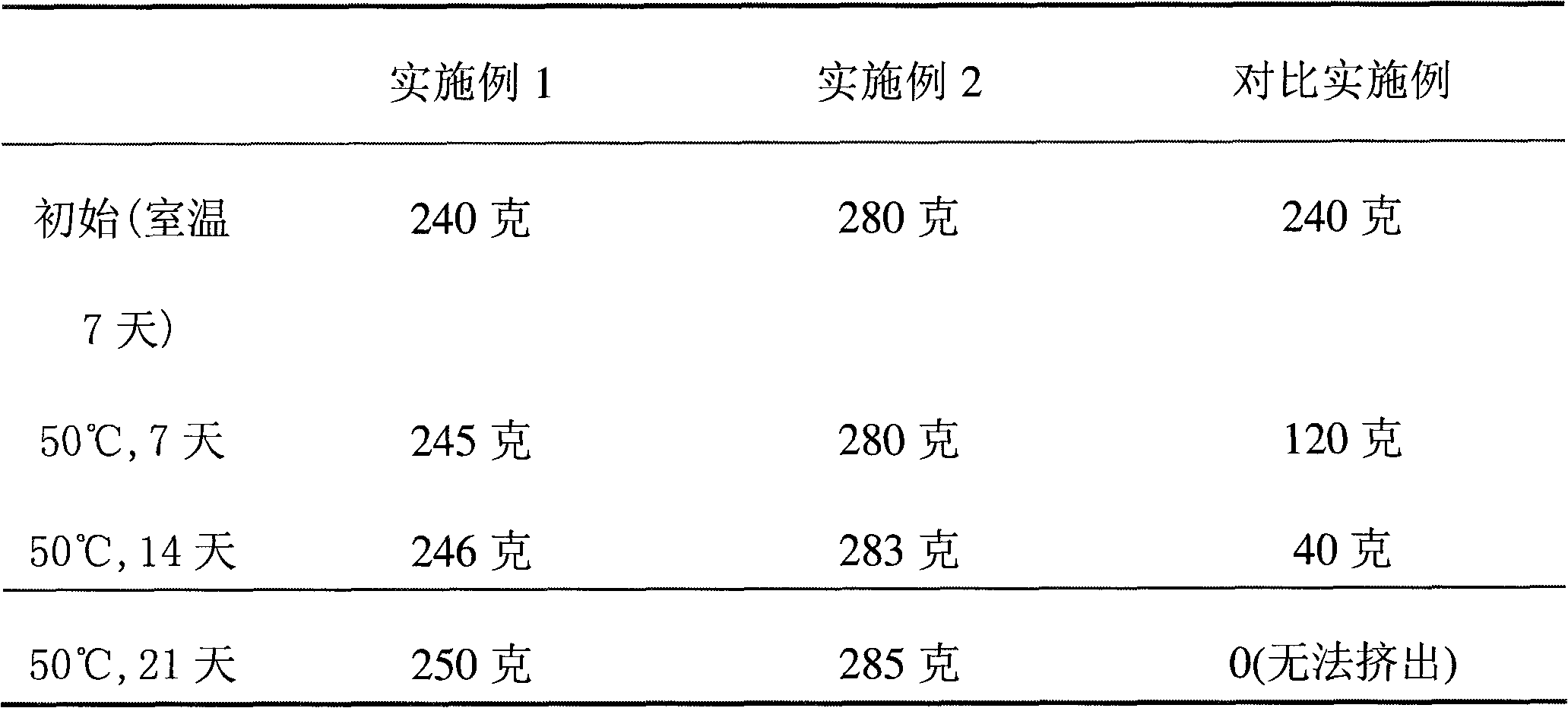

Embodiment 1

[0026] 8000 grams of polyoxypropylene glycol (average molecular weight 8000) was added to the reactor with mechanical stirring, nitrogen protection and heating device. Under the protection of nitrogen, heat the above mixture to 50℃, then add 261 grams of toluene diisocyanate, stir evenly, add 0.1 grams of dibutyltin dilaurate, stir for 2h, then add methylaminopropylmethyldimethoxy Silane 177g, continue to react for 2h to obtain silane-terminated polymer.

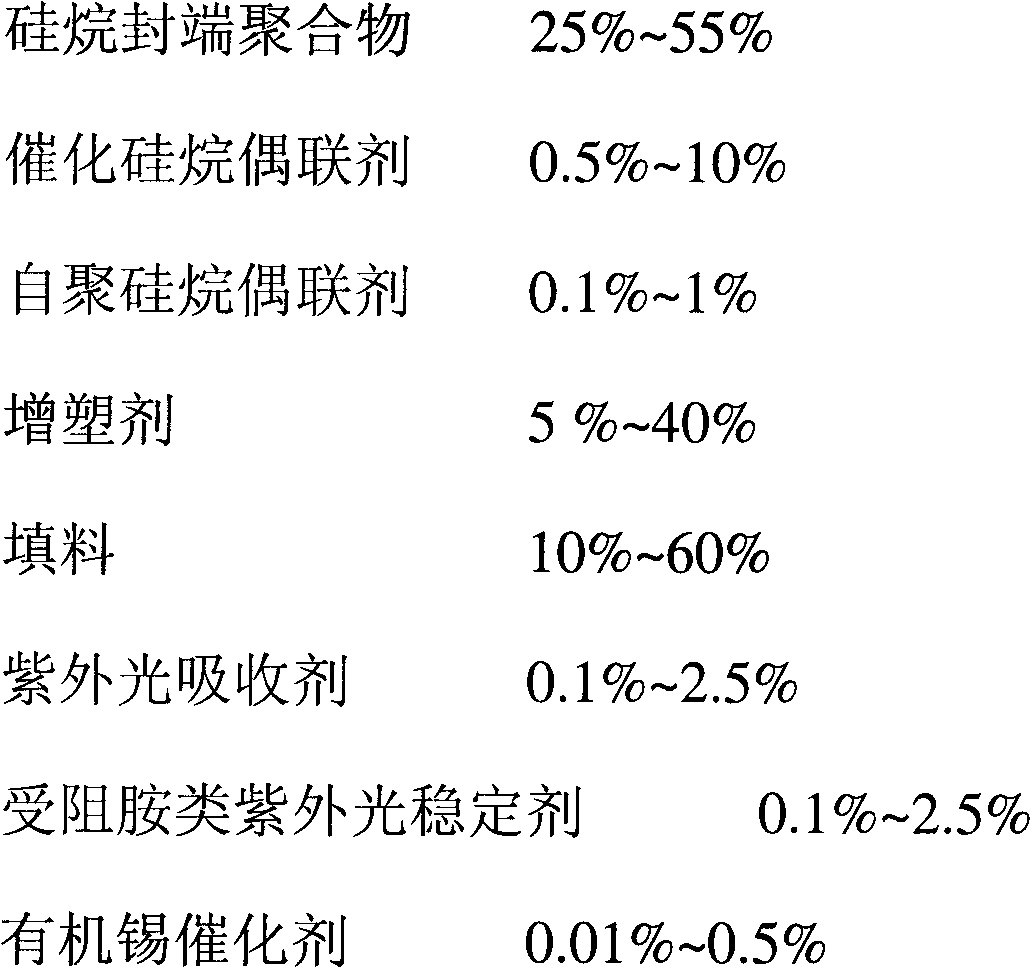

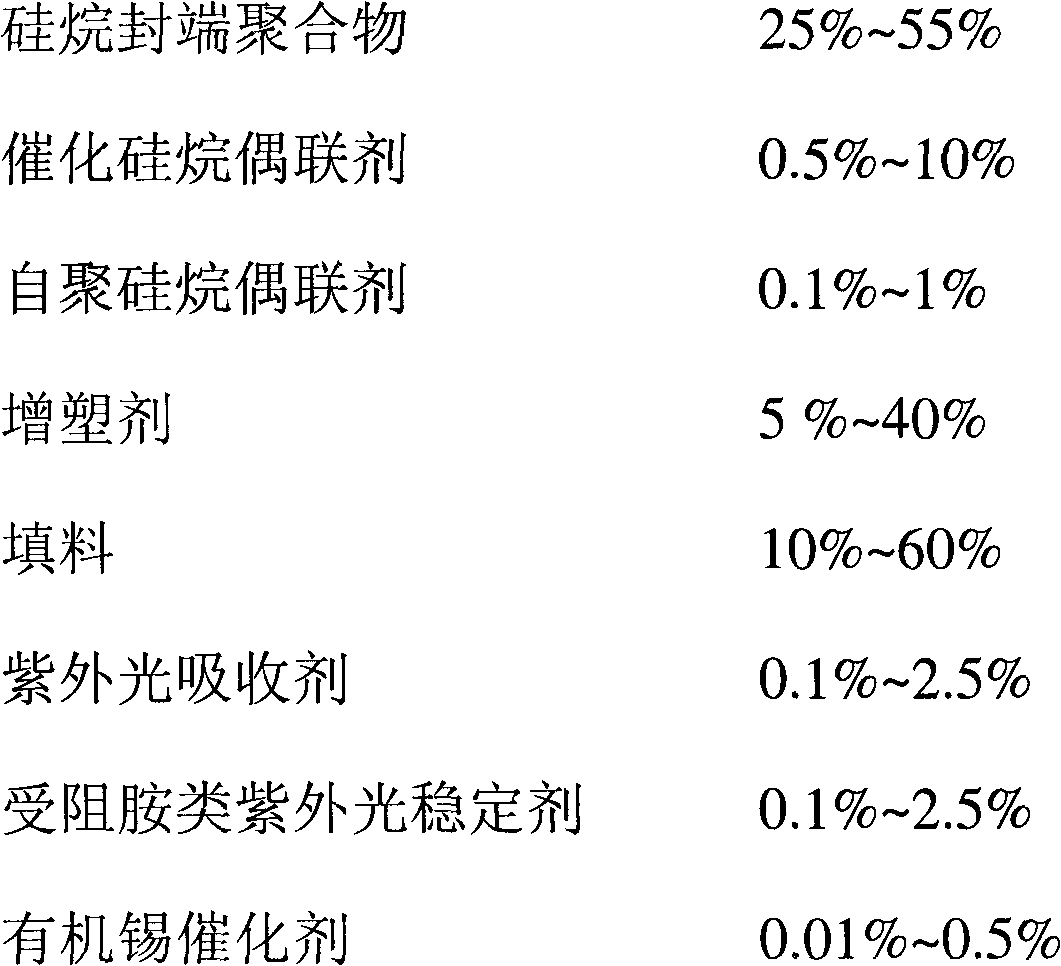

[0027] Add 500 grams of silane-terminated polymer, 5 grams of adhesion promoter N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, and stabilizer vinyl trimethoxysilane to the stirred tank at room temperature. Silane 5g, plasticizer diisodecyl phthalate 200g, surface treated light calcium carbonate 600g, catalyst 15g dibutyltin dilaurate, UV absorber 10g, UV stabilizer 10g, after Mix uniformly under vacuum protection to obtain a thixotropic silane-terminated polymer sealant.

Embodiment 2

[0029] 12,000 grams of polyoxypropylene glycol (average molecular weight of 12,000) was added to a reactor equipped with mechanical stirring, nitrogen protection and heating devices. Under the protection of nitrogen, heat the above mixture to 60℃, then add 444.6 g of isophorone diisocyanate, stir evenly, add 0.1 g of dibutyltin dilaurate, stir for 4h, then add methylaminopropyl methyl di Methoxysilane 354g, continue to react for 2h to obtain silane-terminated polymer.

[0030] Add 500 grams of silane-terminated polymer, 6 grams of adhesion promoter N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, and stabilizer vinyl trimethoxysilane to the stirred tank at room temperature. Silane 5g, plasticizer diisodecyl phthalate 200g, surface-treated light calcium carbonate 600g, catalyst 15g dibutyltin dilaurate, UV absorber 10g, UV stabilizer 10g, after Mix uniformly under vacuum protection to obtain a thixotropic silane-terminated polymer sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com